Automatic charging and tire accepting device of tire base

An automatic feeding and tire base technology, applied in lamination devices, chemical instruments and methods, layered products, etc., can solve problems such as heavy workload, impact on safety, improper operation, etc., to ensure quality and ensure reliability. , the effect of reliable positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, further illustrate the present invention.

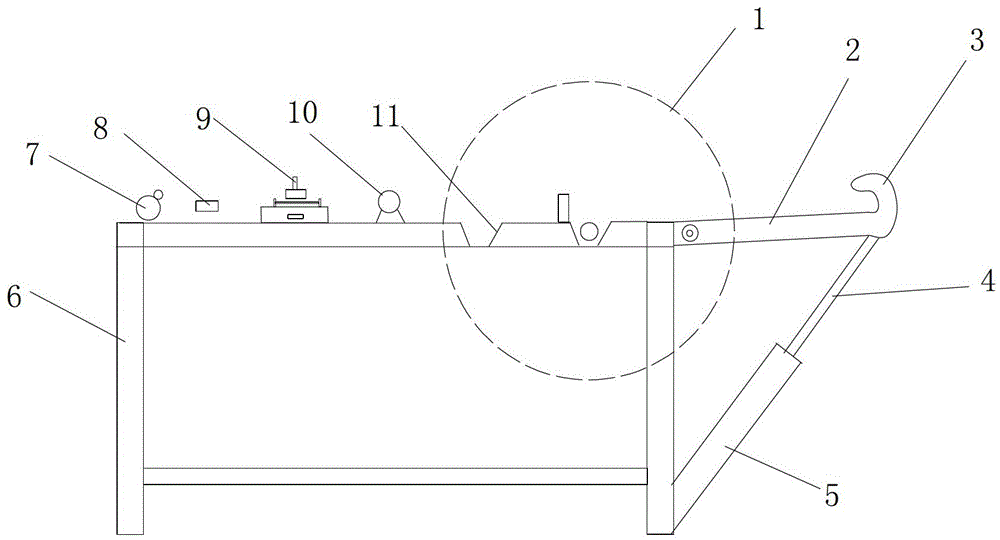

[0020] Such as figure 1 In the shown automatic feeding device for tire base, one end of the frame 6 is hinged with the movable rod 2, and a cylinder 5 is arranged at the bottom of the frame 6, and the telescopic rod 4 of the cylinder 5 is connected with the outer end of the movable rod 4, and the telescopic rod 4 telescopic control movable rod 2 swings up and down. The outer end of movable bar 2 is hook shape 3, and hook shape 3 is upward. The outer end of the movable rod 2 is higher than the inner end of the movable rod 2 and is inclined. A tire base positioning groove 11 is set near the movable rod 2 on the frame 6 . The rear end that is positioned at positioning groove 11 on the frame 6 is also provided with tire base feeding roller 10, tire base quick connector 9, connects compactor 8, tire base counter and tire base roller 7.

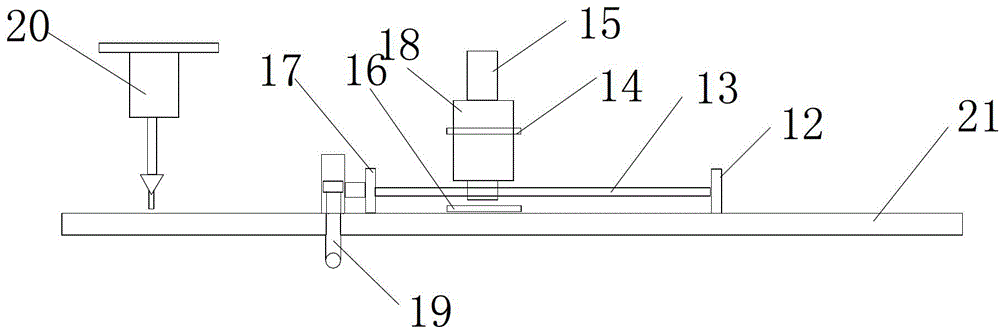

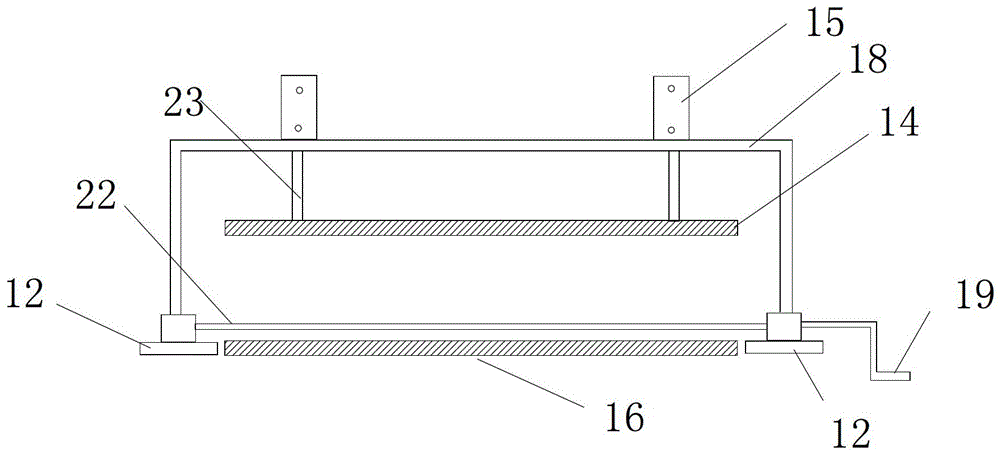

[0021] Such as figure 2 with 3 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com