Manuscript printing quality control method for spot-color ICC (international color consortium) curve proofing

A printing quality and curve technology, applied in the general parts of printing machinery, printing, printing machines and other directions, can solve the problems of uncontrollable effect, stability and continuity, increase quality problems, etc., to save time and cost waste, The effect of reducing quality rework and increasing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] The method for controlling the printing quality of a manuscript by spot color "ICC" curve proofing of the present invention comprises the following steps:

[0017] a. Formulate the printing process and spot color standard for the manuscript sample according to the substrate;

[0018] b. Match the spot color color code of the manuscript with ink from the concave sample, and simulate the customer's printing conditions according to the corresponding process to print the "ICC" color table sample;

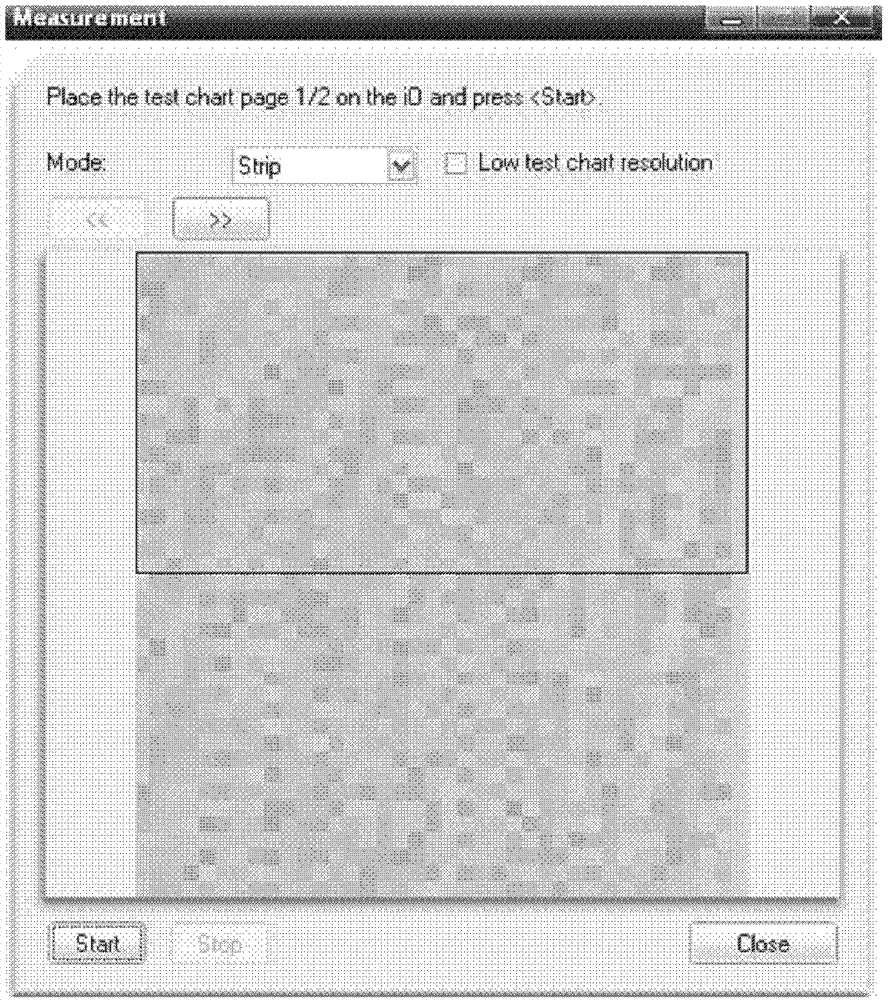

[0019] c. Collect information on the "ICC" color table sample through the Eye-one platform;

[0020] d. Use Profilemaker to generate "ICC" curve;

[0021] e. Print digital proofs through the "ICC" curve to obtain simulated printing effects;

[0022] f. Compare the printed digital proof with the customer's original sample, and apply the color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com