Old frame bridge dismantling method in new-old frame bridge replacing process

A replacement process, frame bridge technology, applied in building maintenance, construction, building construction, etc., can solve problems such as large vibration of breaking hammer, poor safety, instability of railway embankment, etc., to speed up construction progress, reduce construction time, and ensure safety good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The method for dismantling the old frame bridge provided by the present invention in the process of replacing the old frame bridge will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

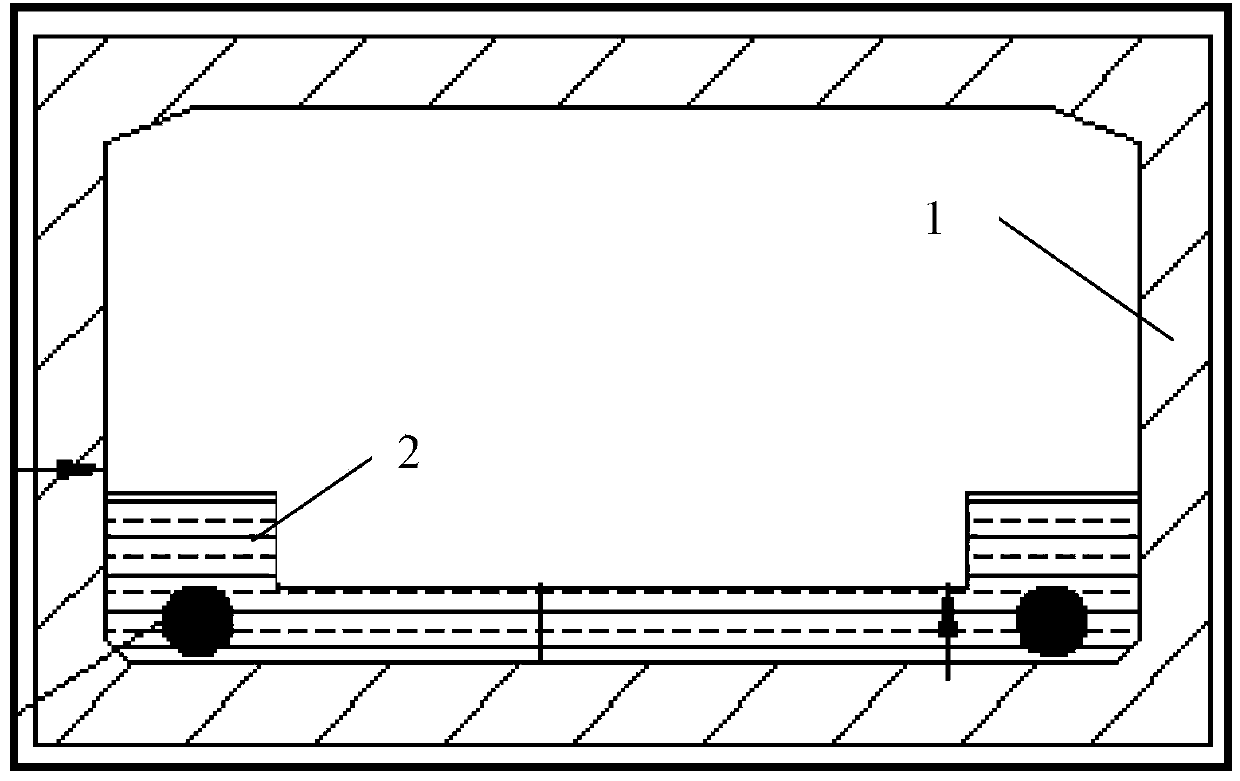

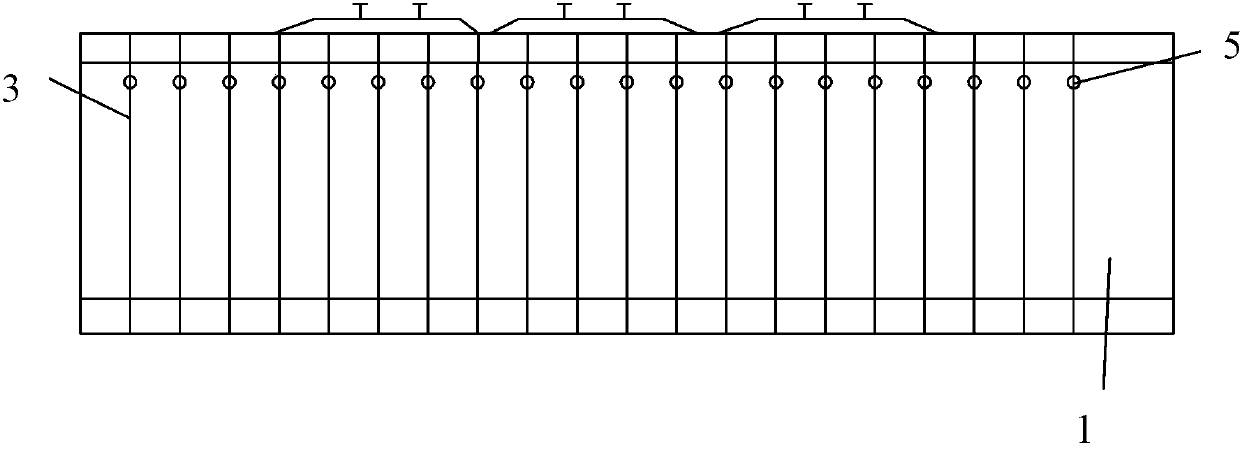

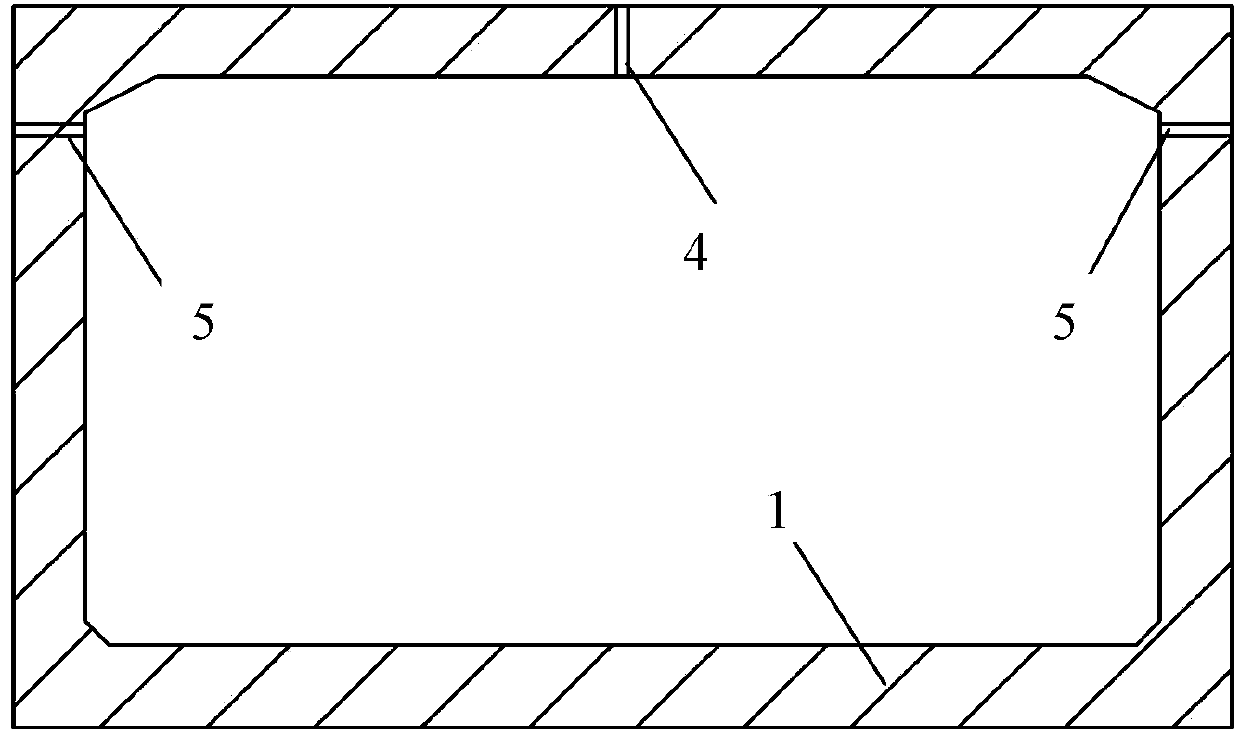

[0021] Such as figure 1 — Figure 4 As shown, the method for dismantling the old frame bridge in the old and new frame bridge replacement process provided by the invention includes the following steps carried out in order:

[0022] 1) First, the existing line above the old frame bridge 1 is reinforced according to commonly used reinforcement methods;

[0023] 2) Use a breaking hammer to break down the sidewalk and road surface 2 in the old frame bridge 1 to be demolished until the concrete floor is exposed;

[0024] 3) On the four inner walls of the old frame bridge 1, a plurality of circles of square cutting lines 3 are made at intervals, thereby dividing the structure of the old frame bridge 1 into multiple sections;

[0025] 4) U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com