Hydraulic hose four way connection joint body

A hydraulic hose and joint body technology, which is applied in the hydraulic field, can solve problems such as oil leakage, misalignment, and poor sealing effect, and achieve the effect of improving the sealing effect and solving misalignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

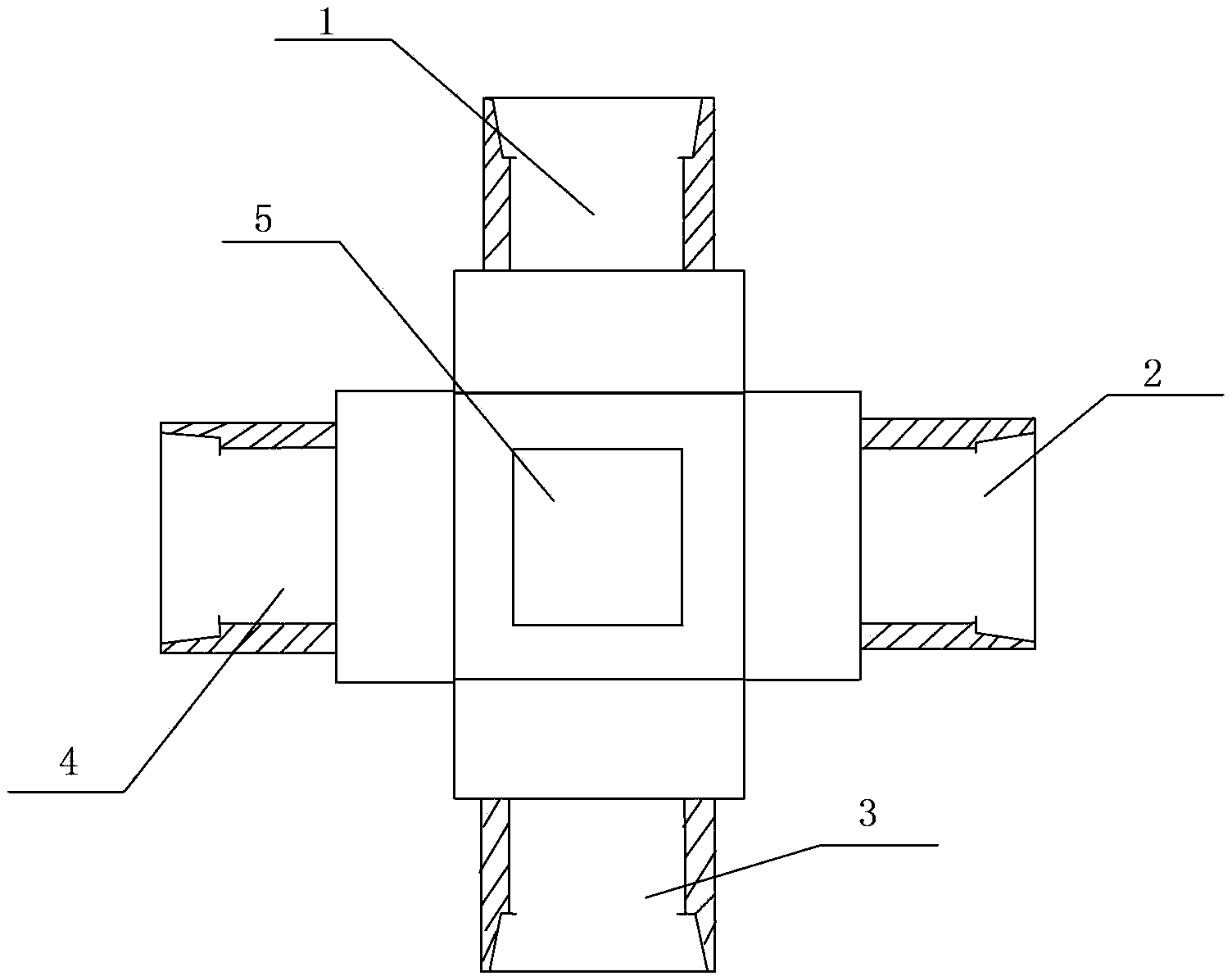

[0010] attached by figure 1 It can be seen that the present invention includes a main body 5, which is composed of four passages: passage I1, passage II2, passage III3 and passage IV4. There are threads on the outside of each passage, that is, the four-way joint body is connected with a hose joint with a nut, and the inner diameter of each passage gradually expands from the inside to the outside, with a flaring design. The four pathways are distributed in a criss-cross manner in the same plane.

[0011] When in use, the inner core of the hose joint with a nut that needs to be connected is first inserted into the passage, and then the nut is tightened. Since each channel is designed with flaring, the hose joint is inserted into the four-way joint body during connection, which not only completely solves the problem of misalignment, but also greatly improves the sealing effect, and there is no need to worry about gaps at the joint when the hydraulic load increases The situation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com