High-precision full-automatic zero returning compensation type body axis system balance calibration system

A balance calibration and fully automatic technology, which is applied in aerodynamic tests, measuring devices, instruments, etc., can solve problems such as complex equipment structure, difficulty in the exact position of the force point, and increased error, and achieve the effect of improving time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

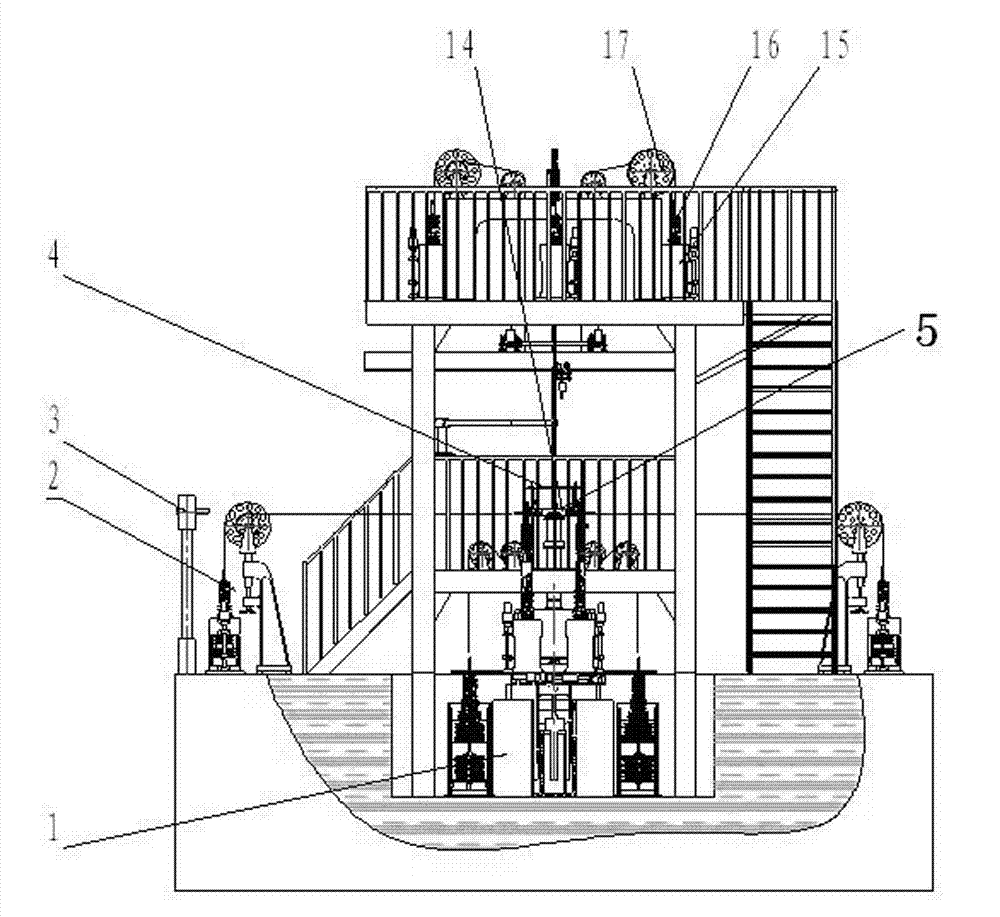

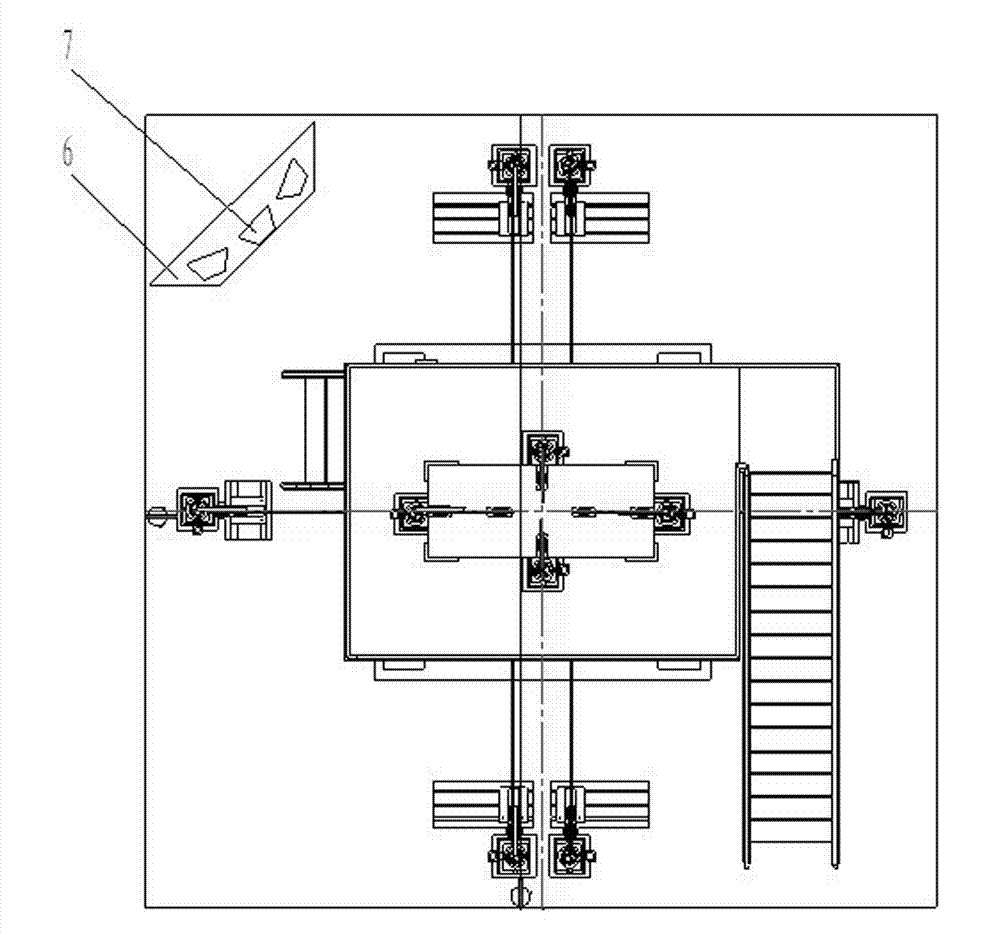

[0037] High-precision full-automatic zero-return compensation type body axis balance calibration system, including reset subsystem 1, loading subsystem 2, loading head initial positioning subsystem 3, reset measurement subsystem 4, box balance 5, control subsystem 6 and software subsystem7.

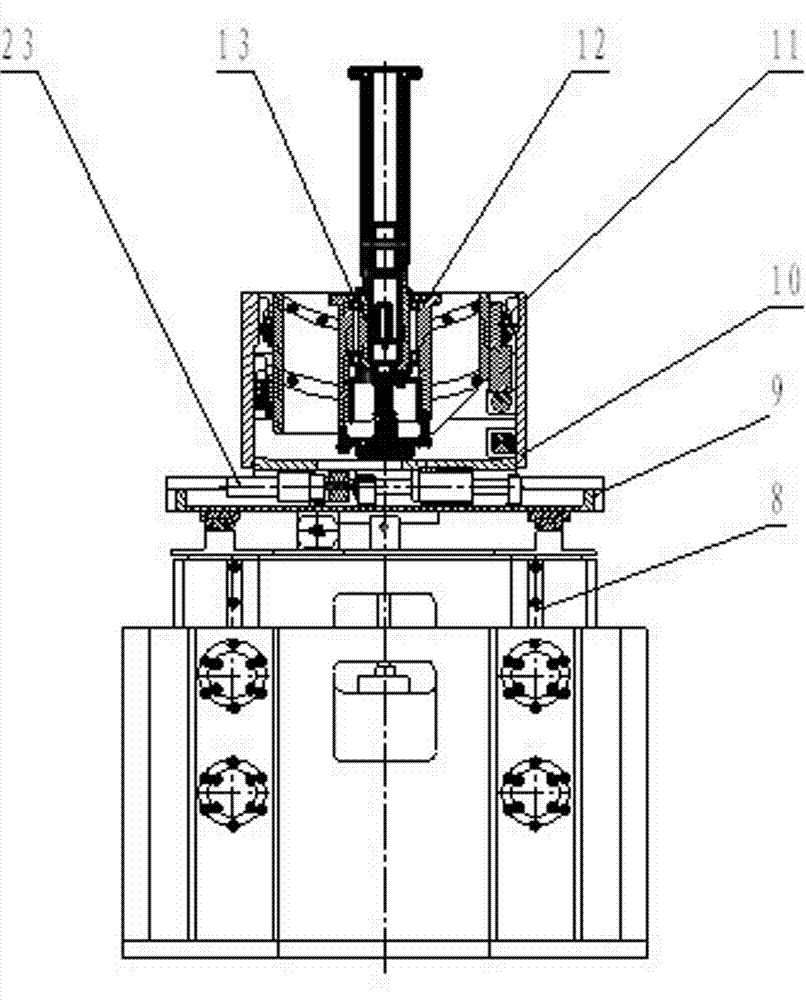

[0038]The reset subsystem 1 includes a normal linear motion mechanism 8 , an axial linear motion mechanism 9 , a lateral linear motion mechanism 10 , a pitch angle motion mechanism 11 , a roll angle motion mechanism 12 and a sideslip angle motion mechanism 13 . The normal linear motion mechanism 8, the axial linear motion mechanism 9, the lateral linear motion mechanism 10, the pitch angle motion mechanism 11, the roll angle motion mechanism 12 and the sideslip angle motion mechanism 13 are connected in series from bottom to top.

[0039] The loading subsystem 2 includes a box-shaped loading head 14 , a drag device 15 , a weight string 16 , and a force transmission device 17 . Weight str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com