Air inlet blocking mechanism for motor vehicle engine air inlet pressure test

A technology of engine air inlet and air inlet pressure, which is applied in the direction of engine testing, machine/structural component testing, measuring devices, etc. It can solve the problems of inconvenient plugging head and difficult air inlet accurate correspondence, etc., and achieves easy installation The effect of maintenance, high accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

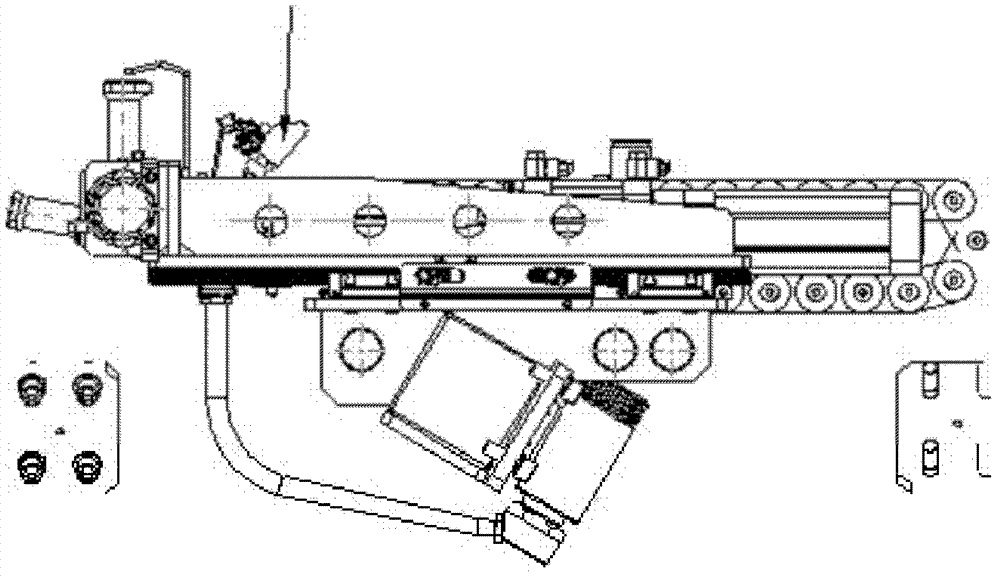

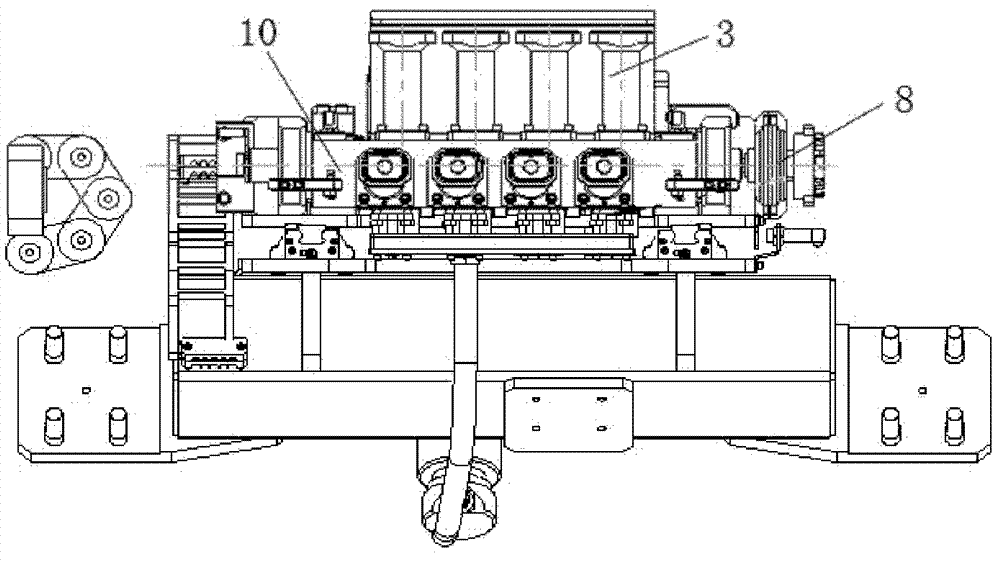

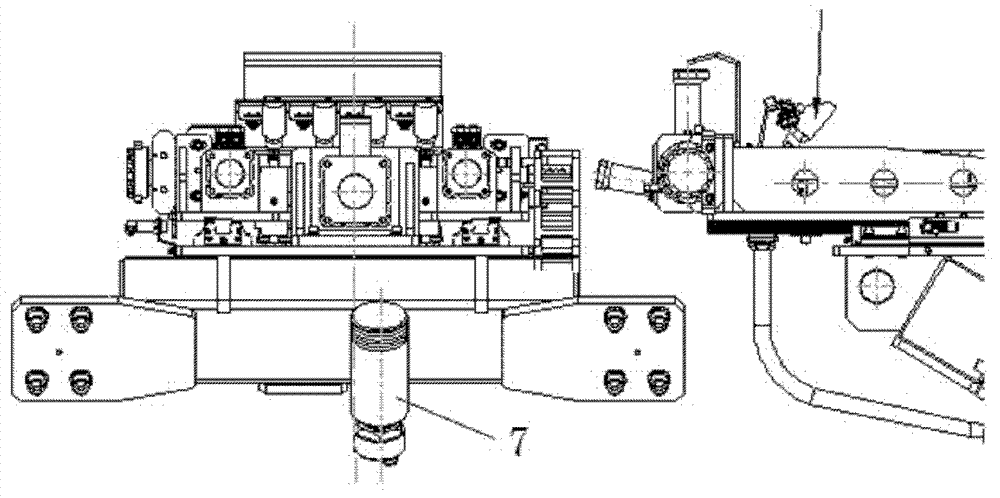

[0040]An air intake blocking mechanism for an air intake pressure test of a motor vehicle engine, comprising: a mobile platform 1 arranged and movable on a fixed bracket; For the plugging heads 3 of the air inlet of the engine under test, the two groups of plugging heads 3 are arranged at an angle of 90°.

[0041] The cylinders 2A, 2B and 2C are arranged on the rear side of the second group of plugging heads 3, the first cylinder 2B is used to push the plugging heads, and the second cylinders 2A-2C drive the intake docking seat 9 to connect with the changing shaft. The pressure sensor 5 and the pneumatic ball valve 6 are arranged on the back side of the plugging head and communicated with the plugging head 3. The intake pressure sensor 5 is used to test the pressure of the engine air inlet, and the pneumatic ball valve 6 is opened according to the test requirements. Or close the passage of the engine exhaust port and the outside atmosphere, which is used to control the breathi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com