Circuit breaker motion mechanism

A technology of action mechanism and circuit breaker, applied in the direction of protection switch operation/release mechanism, etc., which can solve the problems of long inherent time of action mechanism and difficulty in absorbing and extinguishing arcs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

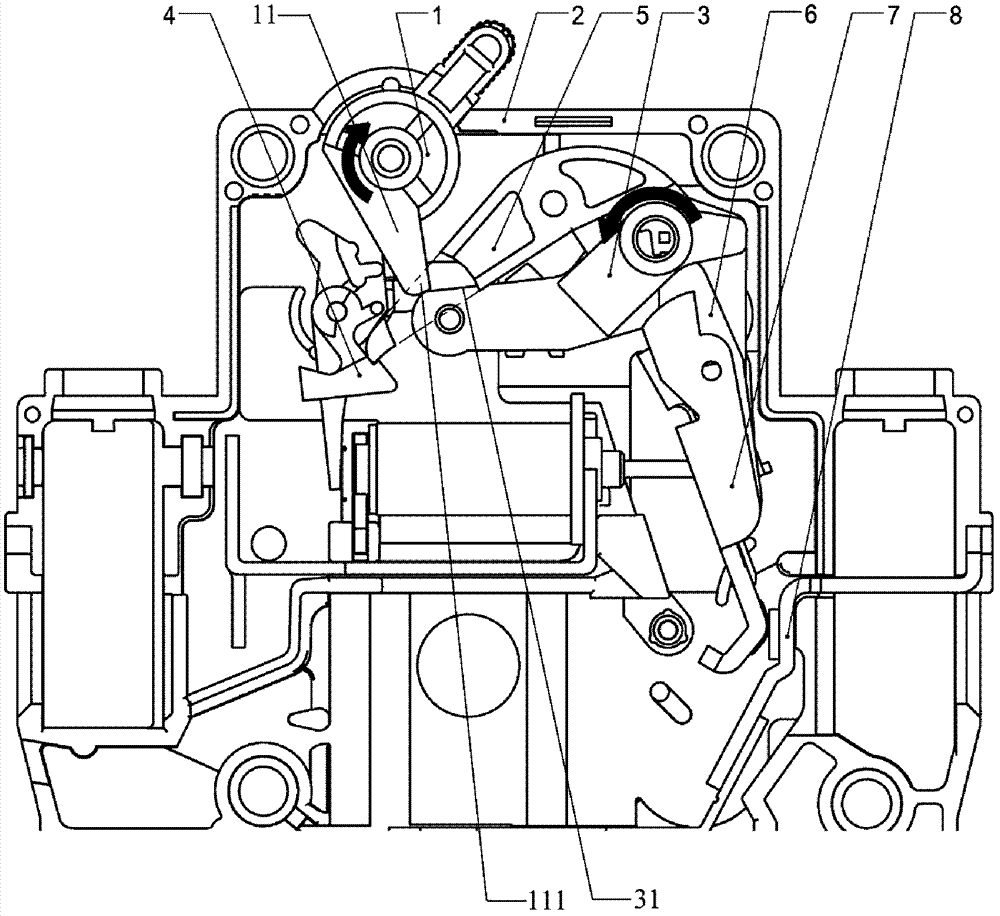

[0016] Such as figure 1 As shown, the operating mechanism of the circuit breaker of the present invention includes the handle 1, the upper link 3 and the movable contact 7 installed in the base 2, but there is no U-shaped link between the handle 1 and the upper link 3, and no other The connecting member, but protrudes a swing arm 11 from the handle. In this preferred embodiment, the swing arm 11 and the handle 1 are integrally formed, and the movable contact 7 is rotatably connected to a bracket 6 .

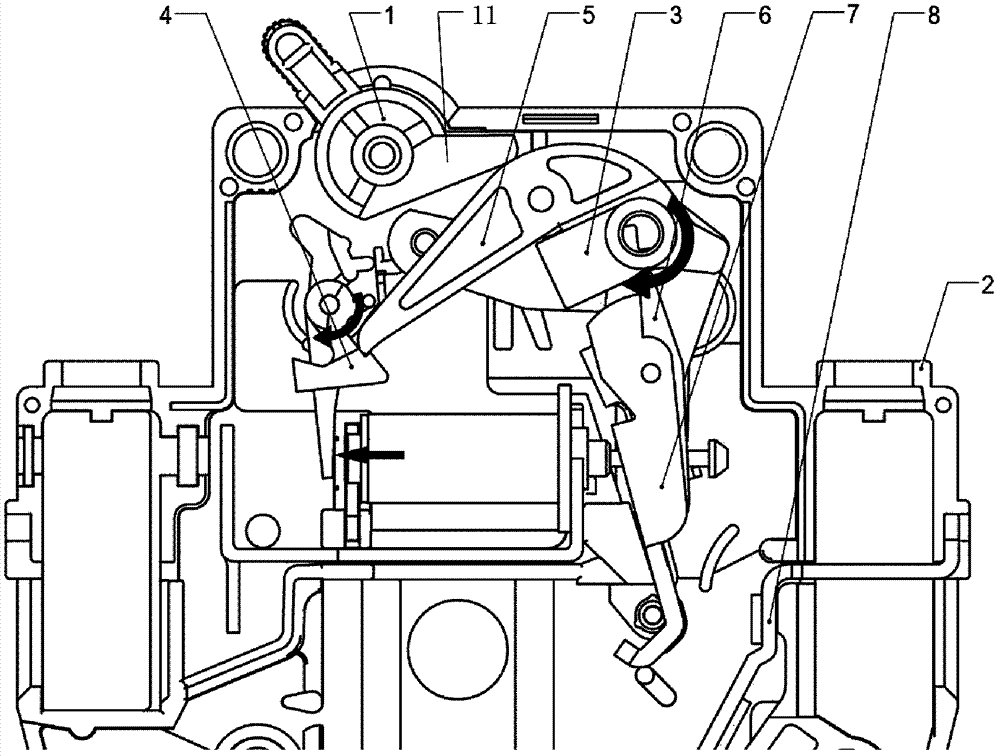

[0017] In the open state, such as figure 2 As shown, the handle 1 including the swing arm 11 is not in contact with the upper link 3 and is completely separated.

[0018] Only when turning the handle to close, such as figure 1 When the handle 1 is turned clockwise, the lower end 111 of the swing arm will come into contact with the upper surface 31 of the upper link and generate sliding friction, thereby pushing the upper link 3 to rotate, and then the link will drive the lock...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com