LED drive circuit

A technology of LED drive and circuit, applied in the direction of lamp circuit layout, electric light source, lighting device, etc., can solve the problems of high cost and complicated drive circuit, and achieve the effect of simple and reliable circuit, scattered heat loss and reasonable setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

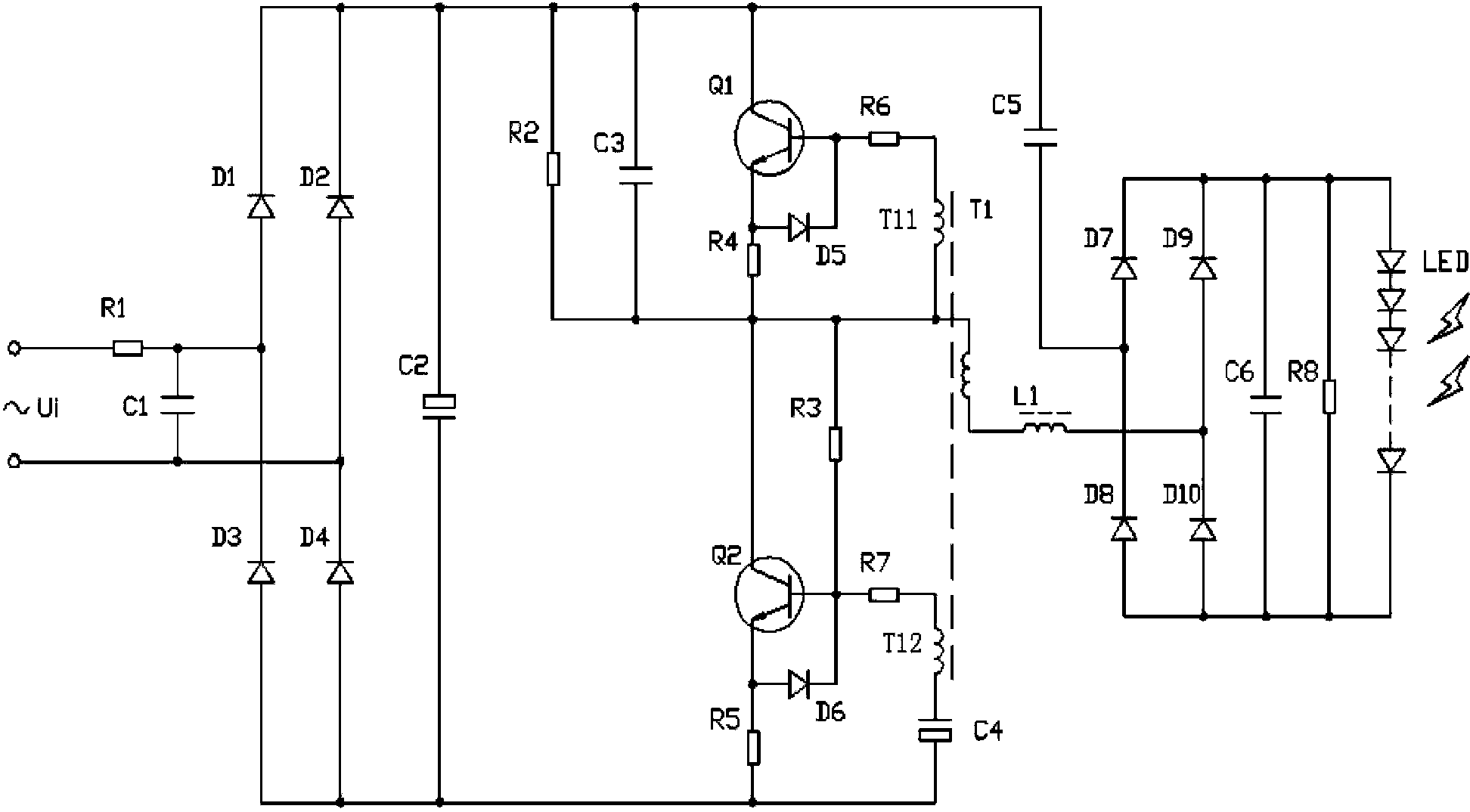

[0009] Such as figure 1 As shown, an LED drive circuit, the power supply Ui is connected to the two AC input ports of the rectification and filtering circuit composed of diodes D1, D2, D3 and D4 through the insurance resistor R1 and X capacitor C1, and the rectification output of the rectification and filtering circuit is positive and output The capacitor C2 is connected between the negative poles, the collector of the transistor Q1 is connected to the positive output of the rectifier filter circuit, the emitter of the transistor Q1 is connected to the collector of the transistor Q2 through the bias resistor R4, and the emitter of the transistor Q2 is connected to the rectifier through the bias resistor R5 The output cathode of the filter circuit, the diode D5 and the diode D6 are respectively connected between the base and the emitter of the transistor Q1 and the transistor Q2, the resistor R2 and the resistor R3 are connected in series, the resistor R2 is connected to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com