Clamping tool

A technology of tools and jaws, which is applied in the field of clamping tools, can solve problems such as excessive hand force, wear of terminal resistance and socket, damage to terminal resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

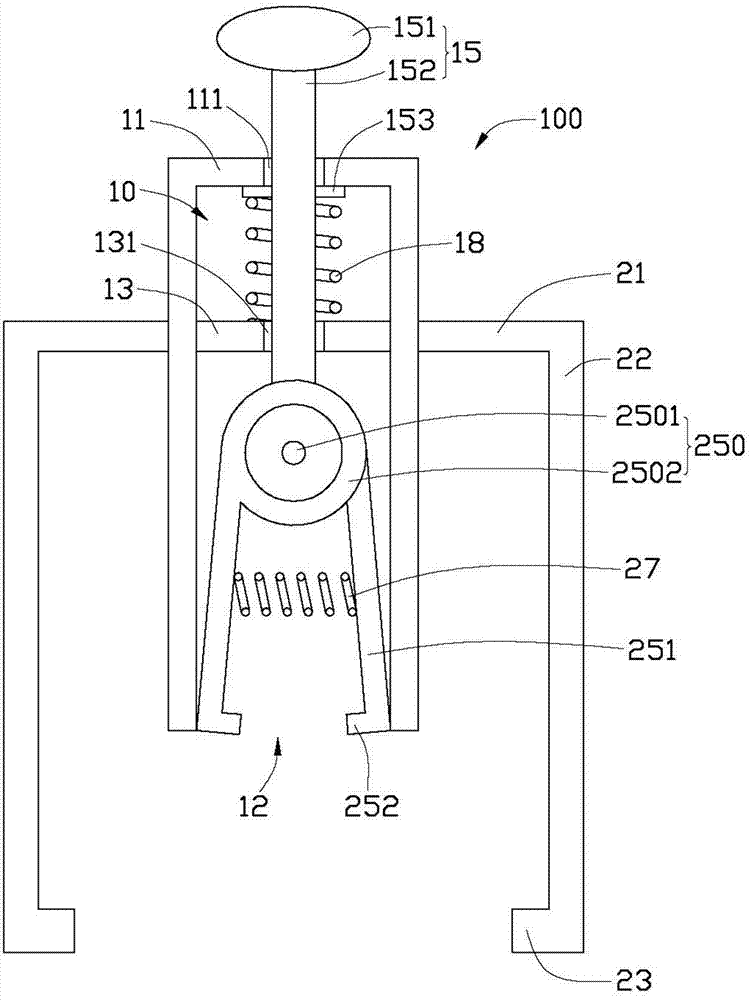

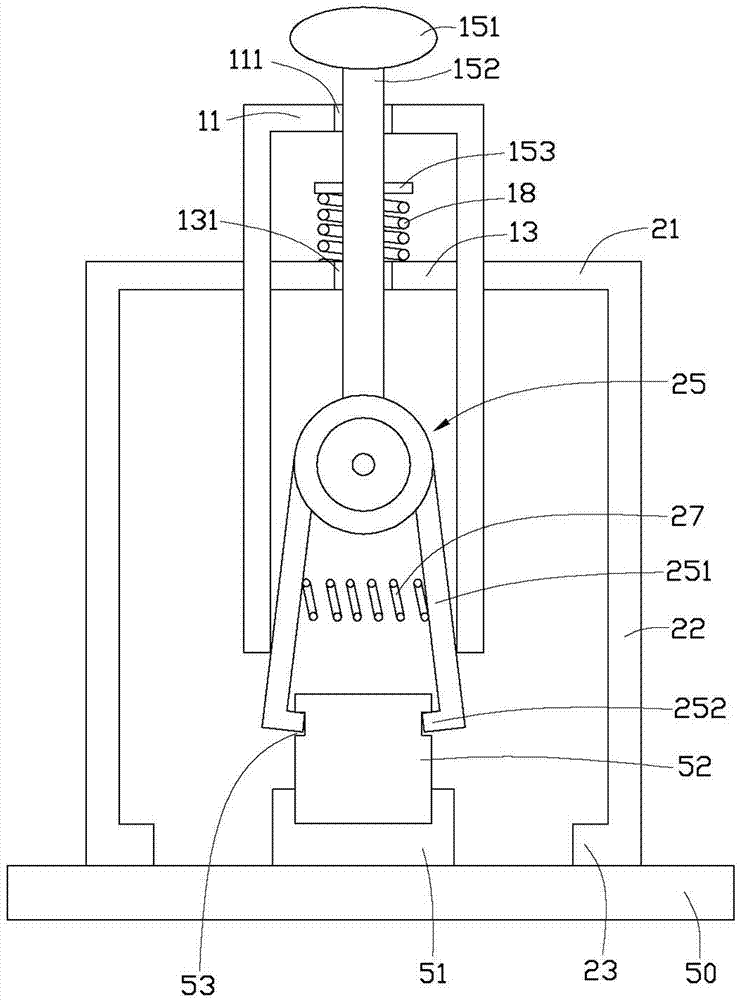

[0011] See figure 1 versus figure 2 The clamping tool 100 of the preferred embodiment of the present invention is used to clamp a workpiece, such as a terminal resistor 52 inserted into a socket 51 of a circuit board 50. A card slot 53 is provided on the outer periphery of the terminal resistor 52. The clamping tool 100 includes a main body 10, a handle 15, a bracket 20 and a clamping part 25. The clamping portion 25 is slidably mounted in the main body 10, the hand lever 15 is slidably mounted on the main body 10 and is elastically connected to the clamping portion 25, and the bracket 20 is fixed to the outside of the main body 10 to support the clamping tool , Pushing the hand lever 15 to expose the clamping portion 25 to the body 10 to clamp the workpiece.

[0012] The main body 10 is a cylindrical cylinder formed by the relative combination of two hollow semi-cylinders. The body 10 includes an end wall 11, an opening 12 and a resisting plate 13. The end wall 11 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com