Bulb lamp and manufacturing method thereof

A bulb lamp and LED bulb lamp technology, applied in the LED field, can solve the problems of not being able to substantially improve the quantitative control of the illumination range, uneven luminescence, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following discussion belongs to but does not limit the protection scope of the claims of the present invention, and the claims shall prevail when judging the rights.

[0035] The realization of the present invention is based on the following two points of consensus:

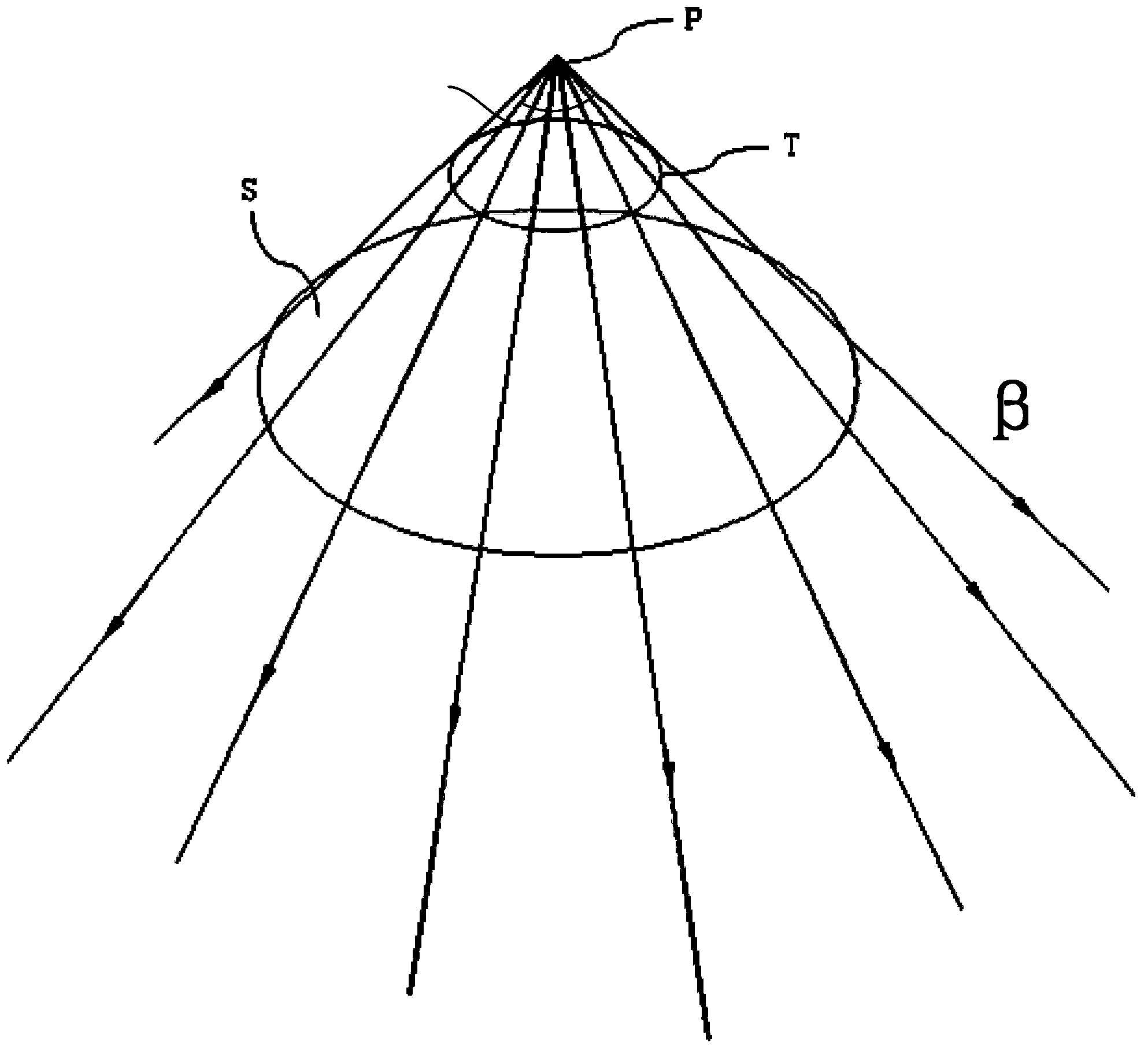

[0036] 1. In principle, the bulb lamp with built-in point light source can project light to any place except the dark area formed by the shading part of the lamp body;

[0037] 2. For a bulb with a reasonable design, the area that cannot be illuminated by the LED chip closest to the shading part of the lamp body will form a blind area for lighting of the bulb.

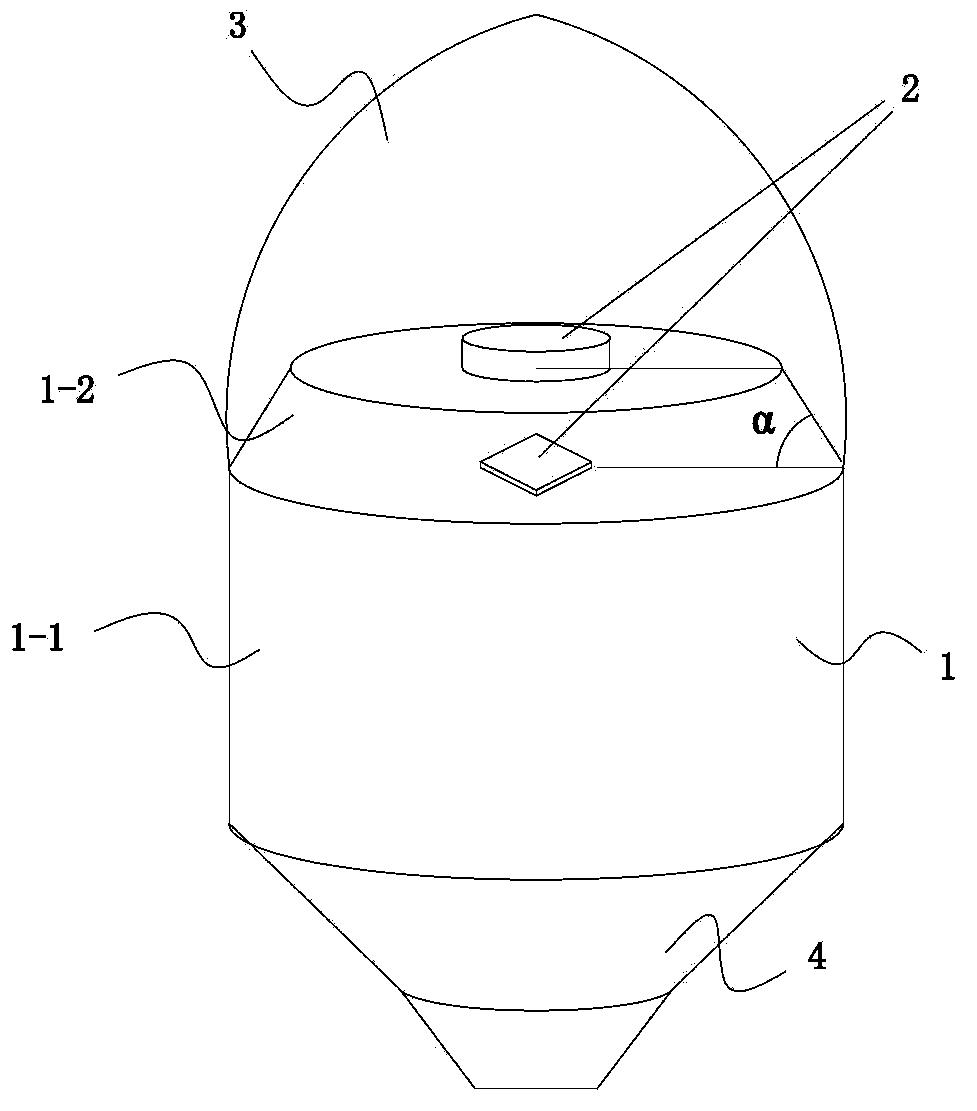

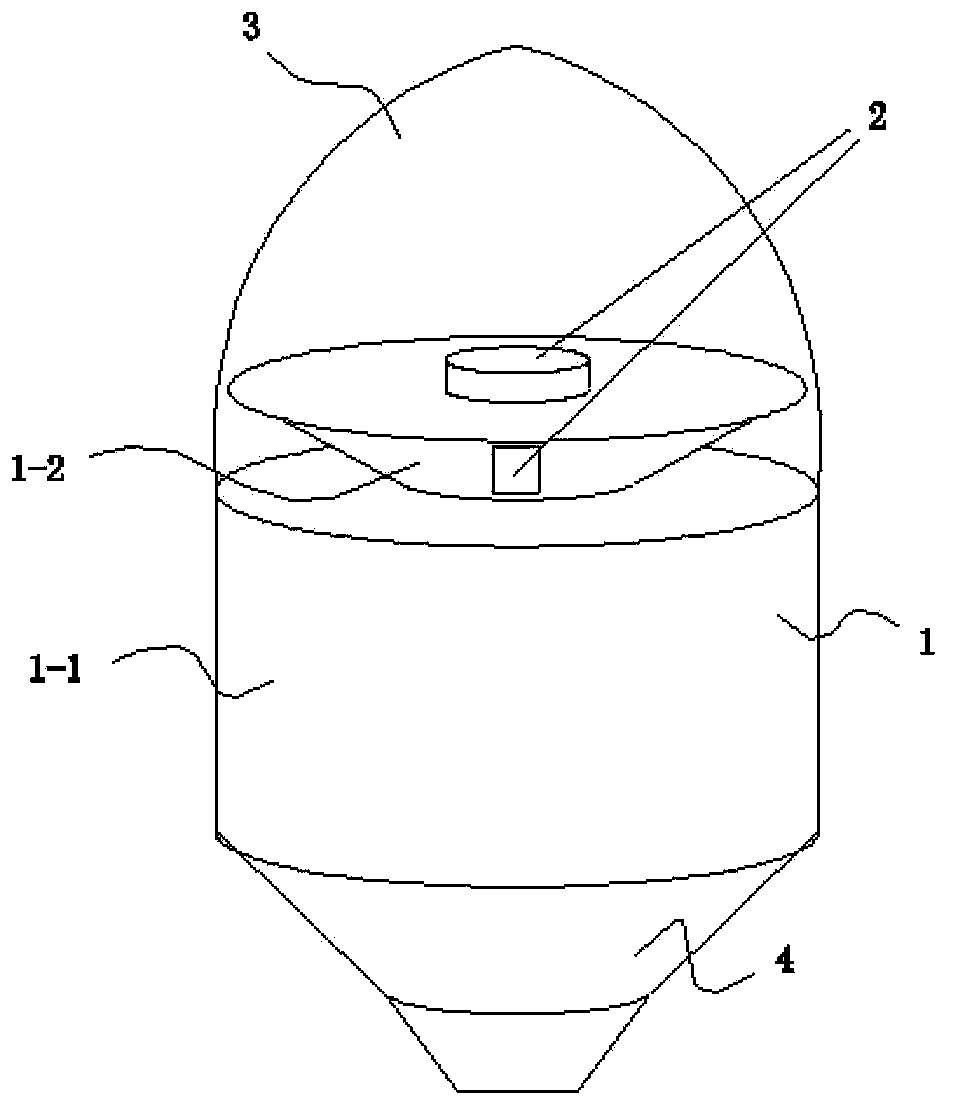

[0038] In a preferred embodiment, see figure 2 , The bulb lamp includes a transparent lampshade 3 , a lamp body 1 , four LED chips 2 and a lamp cap 4 . The lamp body 1 includes a cylindrical part 1-1 and a conical part 1-2, wherein the conical part 1-2 is used for installing LED chips. The cylinder part 1-1 and the frustum part 1-2 of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com