Photovoltaic junction box

A technology for photovoltaic junction boxes and box covers, which is applied in the field of photovoltaic junction boxes, and can solve problems such as the inability to fix the upper cover and box cover, and colloid melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

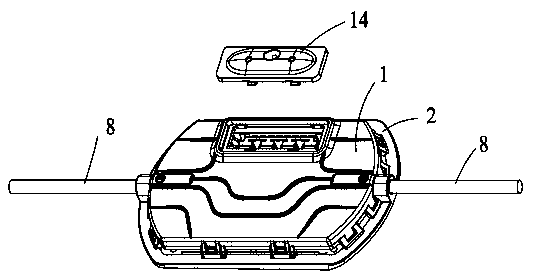

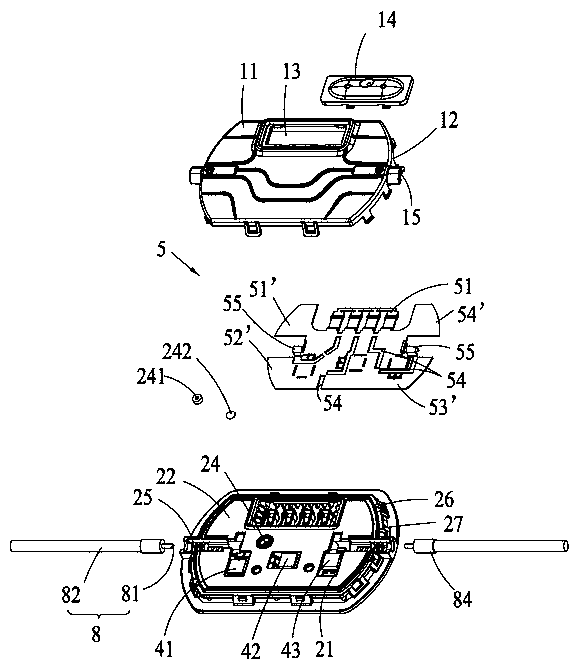

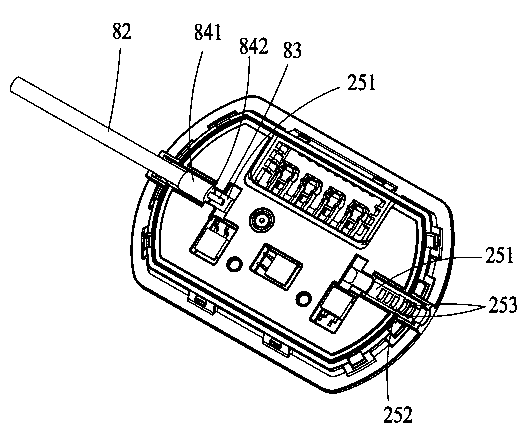

[0020] See figure 1 , a photovoltaic junction box, including a box body 2, a box cover 1 cooperating with the box body 2, a copper plate 5 arranged in the box body 2, four busbars (not shown), and two electrically connected copper plates 5 Cables, and cables 8 are used to lead the cables 8 from the outside of the photovoltaic junction box into the cable grooves in the photovoltaic junction box box. Part of the cables 8 are accommodated in the cable grooves. The metal connecting ends 51 are electrically connected one-to-one.

[0021] See Figure 4 , 5 The box cover 1 includes a cover body 11, a side plate 12 extending downward from the edge of the cover body 11, and an upper cover 14 snap-fitted to the cover body 11. The cover body 11 has a penetrating The glue filling area 13 of the cover body 11 and the upper cover plate 14 are used to cover the glue filling area 13 . In this embodiment, the buckle connection between the cover body 11 and the upper cover plate 14 adopts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com