A compound milling cutter

A milling cutter and compound cutting technology, used in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of casualties, overall destructiveness, loss, etc., to enhance the crack resistance, expand the scope of application, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

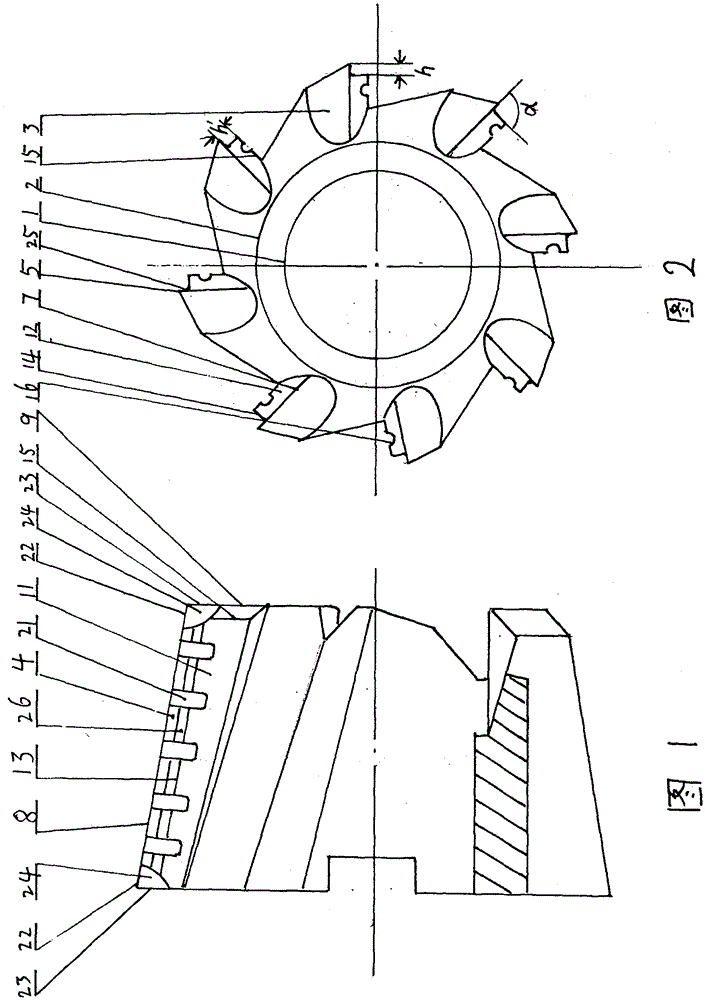

[0043] like Figure 1-2 As shown, the compound milling cutter according to the first embodiment of the present invention, in particular, relates to various compound shell end mills, including a tool shank or a positioning hole 1 and a tool head 2, the tool shank or positioning hole 1 and a tool head 2 connected or formed as one, the tool head 2 is integrally provided with a plurality of cutting blades 3, on the cutting surface 4 of each cutting blade 3, the rear side or the back side of the cutting surface 4 facing the cutting direction is post cutting Face 5 or side cutting surface 7, and cutting surface 4 intersects with rear cutting surface 5 or side cutting surface 7 to form at least one cutting edge 8, or at least one side cutting edge 9, and the compound milling cutter involves various concave and convex Semicircle milling cutters, or various keyway milling cutters, or various T-slot milling cutters, or various straight shank reverse dovetail groove milling cutters and va...

Embodiment approach 2

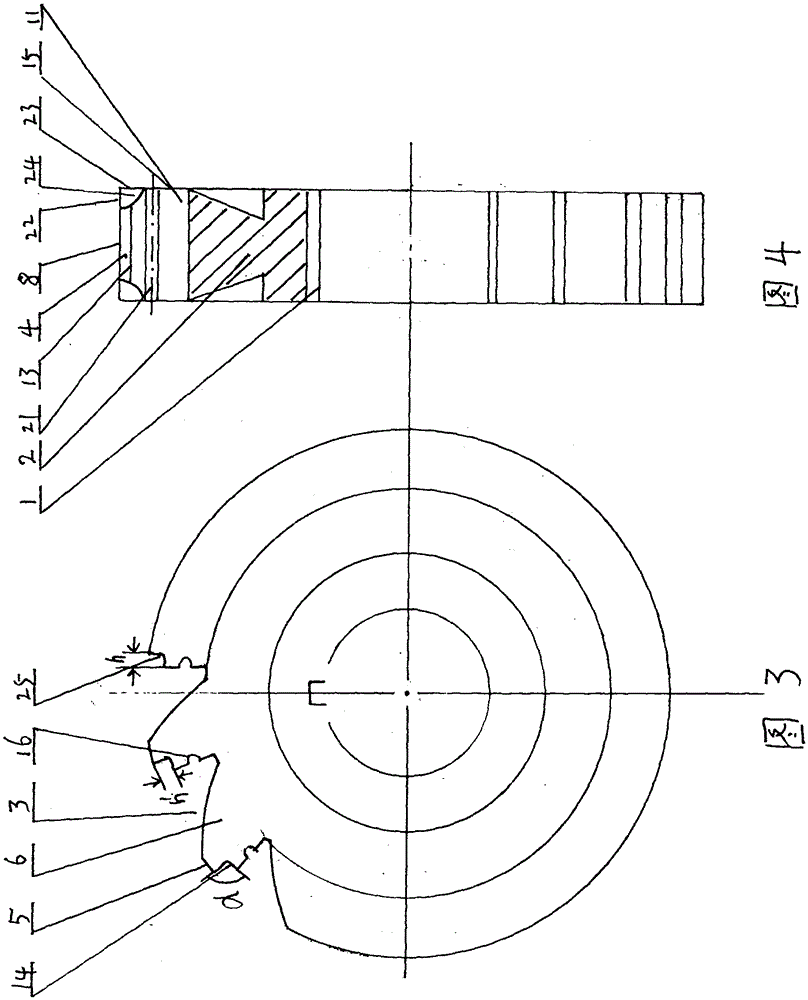

[0046] like Figure 3-4 As shown, the compound milling cutter of the second embodiment of the present invention, specifically relates to various compound saw blade milling cutters, on the basis of the effect of the first embodiment, the present invention includes a positioning hole 1 and a cutter head 2, the cutter The shank or positioning hole 1 and the cutter head 2 are integrally formed, and the cutter head 2 is integrally provided with a plurality of cutting blades 3, and each cutting blade 3 has a cutting surface 4, behind the cutting surface 4 facing the cutting direction. The side or back side is the rear cutting surface 5, or the side cutting surface 6, or the secondary cutting surface 7, and the cutting surface 4 intersects with the rear cutting surface 5 or the side cutting surface 7, forming at least one cutting edge 8, or at least one side cutting surface Edge 9, toward the inboard of the cutting surface on the cutting direction, arc-shaped protrusion or oblique pr...

Embodiment approach 3

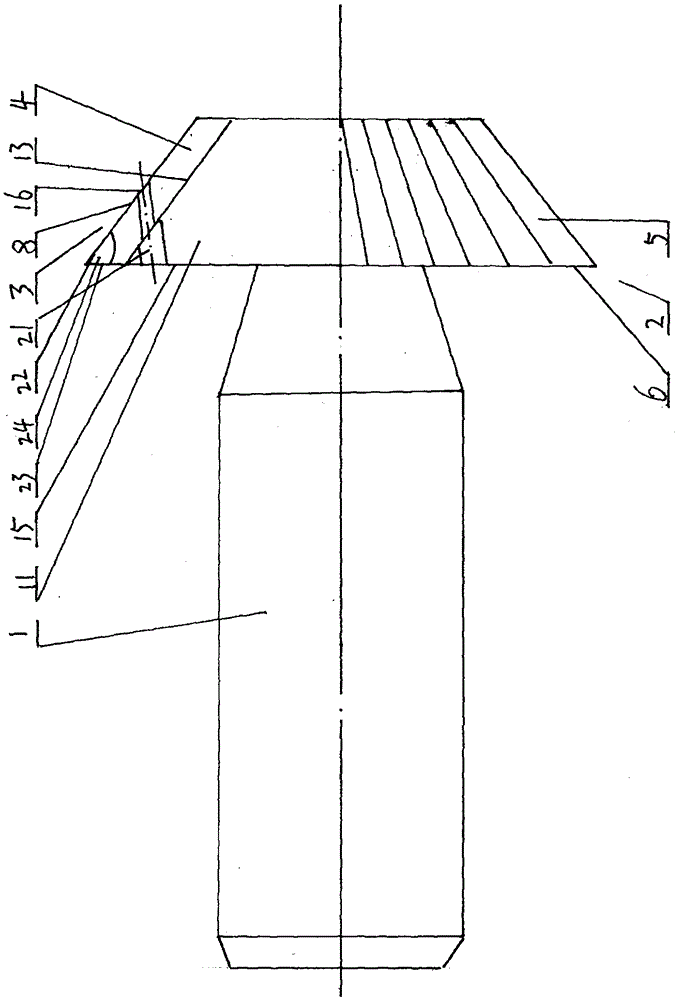

[0049] like Figure 5 Figure 16 As shown, the compound milling cutter of the third embodiment of the present invention, specifically relates to various compound dovetail grooves or compound reverse dovetail groove milling cutters, on the basis of the effects of the first and second embodiments, the present invention includes positioning holes 1 and the tool head 2, the tool handle or positioning hole 1 and the tool head 2 are integrally formed, and the tool head 2 is integrally provided with a plurality of cutting blades 3, and each cutting blade 3 has a cutting surface 4, facing The rear side or back side of the cutting surface 4 in the cutting direction is the rear cutting surface 5, or the side cutting surface 6, or the secondary cutting surface 7, and the cutting surface 4 intersects the rear cutting surface 5 or the side cutting surface 7, forming at least one cutting surface. Edge 8, or at least one side cutting edge 9, towards the inboard of the cutting surface on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com