Positioning device of dedusting and cleaning dolly and positioning method thereof

A technology for cleaning trolleys and positioning devices, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as high labor intensity, dust pollution, and frequent movement of trolleys, so as to reduce labor intensity and improve the use effect. and longevity effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

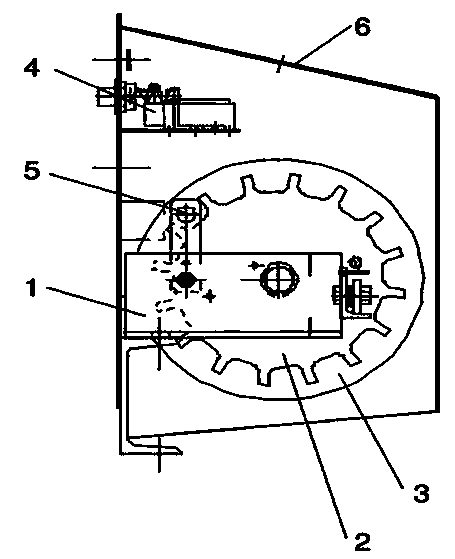

[0011] Example 1 Such as figure 1 Shown: a positioning device for a dust removal and cleaning trolley, including a cleaning trolley pulled by a traction wire rope. The wheels of the cleaning trolley walk along the track laid in front of the suspended dust bag; the bracket 1 connected to the casing 6 is installed on the cleaning trolley On the top, the guide disc 2 with indexing teeth and the sprocket 3 are installed concentrically on the rotating shaft of the bracket 1, and when the cleaning trolley moves forward, the guide disc 2 is driven to rotate by the sprocket 3; the guide disc 2 is indexed An inductive switch 5 is installed on the side of the tooth, and the inductive switch 5 is connected with the programmable controller PLC, and a terminal limit switch 4 is installed at the limit position of the edge.

Embodiment 2

[0012] Example 2 Such as figure 1 Shown: Adopt the positioning method of a positioning device for dust removal and cleaning trolley described in Example 1: the cleaning trolley is pulled by the traction wire rope and walks along the track laid in front of the suspended dust removal bag, and the cleaning trolley is driven to move forward. The guide disc 2 of the tooth rotates; whenever an indexing tooth passes and triggers the induction switch 5 installed on the side of the indexing tooth of the guide disc 2, the induction switch 5 counts once, and the programmable switch connected with the induction switch 5 Write a counting program in the PLC program of the controller, and the cleaning trolley will accurately stop in front of the dust bag that needs to be cleaned and purged, and the exact position of the cleaning trolley can be known through the cumulative calculation of the counting program; when the cleaning trolley moves to the edge limit position, trigger the terminal l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com