Integrated mining excavation and loading machine

An all-in-one machine and mining technology, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problems of poor site adaptability and low excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

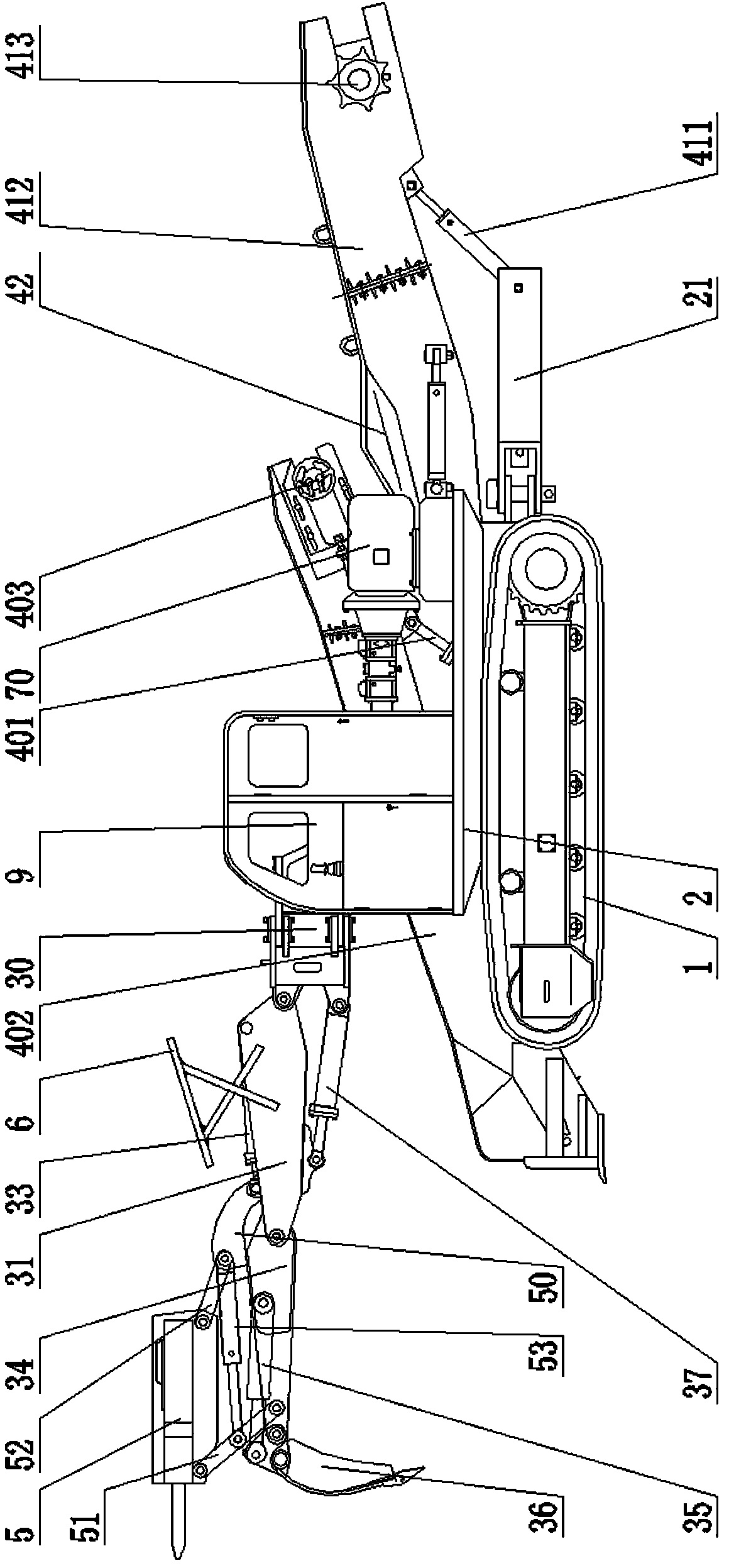

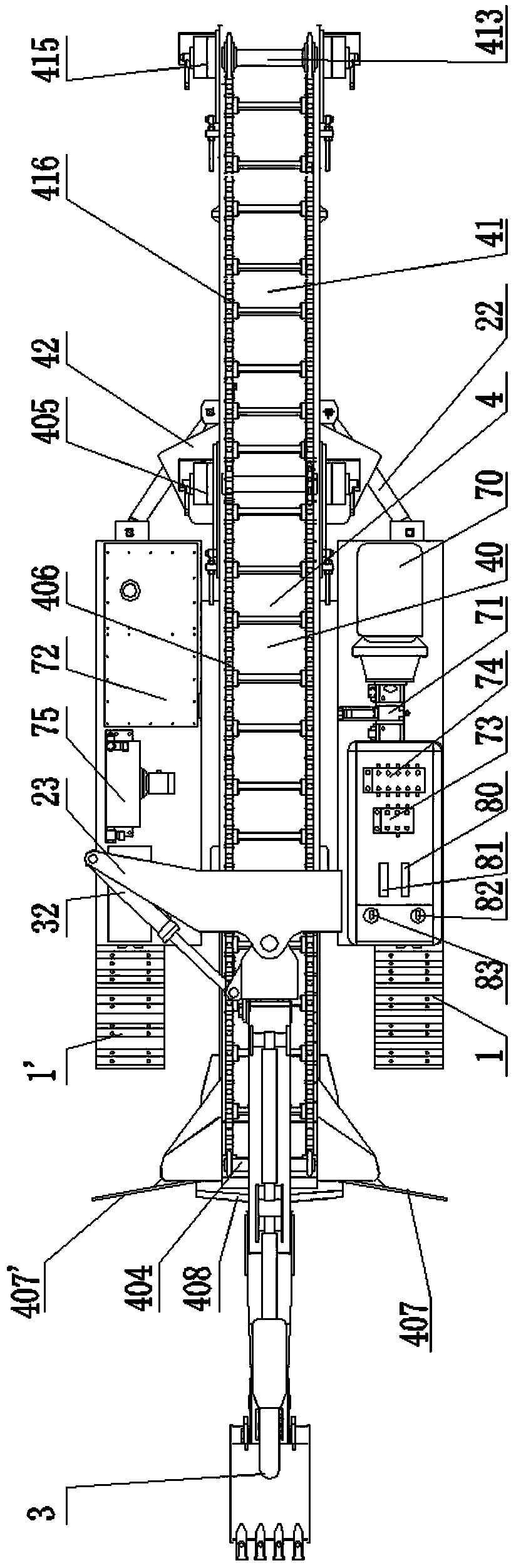

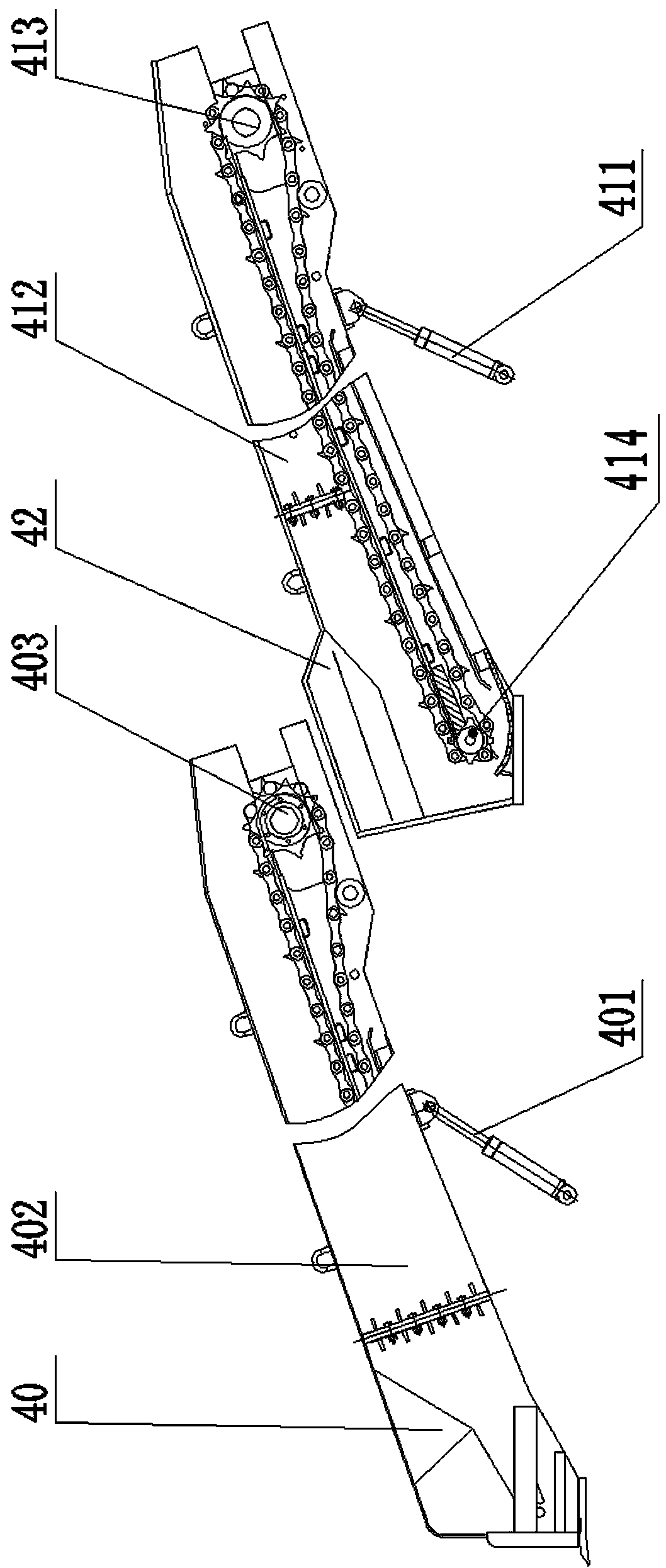

[0021] Such as figure 1 , figure 2 It can be seen that the mining digging and loading machine of the present invention includes left and right traveling mechanisms 1, 1' arranged on both sides. The left and right traveling mechanisms 1, 1' are provided with a frame 2, and also include a set The excavating mechanism 3 in front of the frame 2 is provided with a conveying mechanism 4 on the frame 2 between the left and right traveling mechanisms 1, 1', and also includes a power unit and a manipulation device. The conveying mechanism 4 It includes a front conveying mechanism 40 arranged at the front end of the frame 2 and a rear conveying mechanism 41 arranged at the rear end of the frame 2 which can swing left and right along the axis of the conveying mechanism 4 . A funnel 42 is provided between the tails.

[0022] After adopting the above-mentioned technical scheme,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com