Triangular carbon fiber photoelectricity composite overhead conductor

A photoelectric composite, overhead wire technology, applied in circuits, power cables, electrical components, etc., can solve the problems of inability to realize communication functions, poor wind resistance effect of wires, large galloping amplitude, etc., and achieve good soft performance and improved tensile strength. , reduce the effect of dancing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

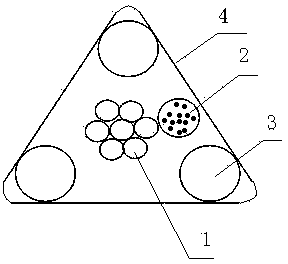

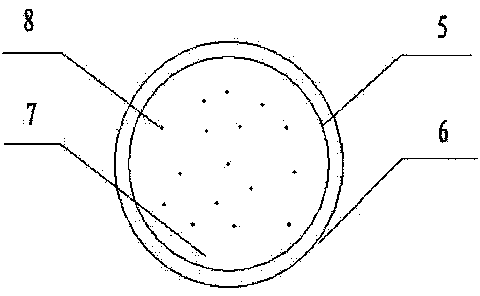

[0023] Such as figure 1 As shown, a triangular carbon fiber photoelectric composite overhead wire includes a photoelectric composite structure composed of a carbon fiber load-bearing member 1, a stainless steel light unit 2 and a hard aluminum round wire 3, and a high-temperature-resistant insulating material layer 4; the high-temperature-resistant insulating material layer 4 The cross-section of the triangular section is triangular, and each corner of the triangular section accommodates a hard aluminum round wire 3, and the center of the cross-section of the high-temperature-resistant insulating material layer accommodates a carbon fiber load-bearing member 1, and the high-temperature-resistant insulating material layer The stainless steel light unit 2 is accommodated in the gap between the duralumin round wire 3 and the carbon fiber load-bearing member 1 in layer 4; the carbon fiber load-bearing member 1 is a composite ultra-high-strength core wire, including high-performance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com