A special-shaped anti-skid pre-twisted wire

A pre-twisted, special-shaped technology, applied in the field of special-shaped anti-slip pre-twisted wires, can solve the problems of inconvenient installation and construction, abrasion of wires, easy wear, etc., and achieve the effects of simple construction, increased friction, and convenient portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

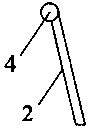

[0028] see figure 1 , is a schematic diagram of the structure of the special-shaped non-slip pre-twisted wire provided in Embodiment 1 of the present invention.

[0029] The special-shaped non-slip pre-twisted wire provided by the embodiment of the present invention includes: a pre-twisted wire body 1, a support end 2, a parallel tail end 5 and an anti-skid layer 3, wherein,

[0030] The pre-twisted wire body 1 is helical, and one end of the pre-twisted wire body 1 is higher than the radial height of the pre-twisted wire body 1;

[0031] Specifically, the overall size of the pre-twisted wire provided in this embodiment is equivalent to half of the size of the existing pre-twisted wire, and on the basis of the existing pre-twisted wire structure, one end of the pre-twisted wire body 1 is increased to make One end of the pre-twisted wire body 1 is obviously higher than the radial height of the pre-twisted wire body 1 . The increased section of the pre-twisted wire body 1 can e...

Embodiment 2

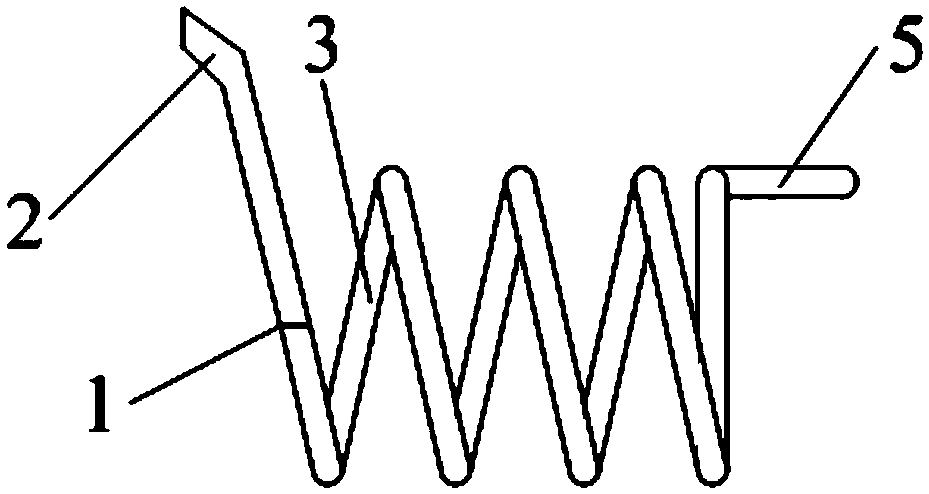

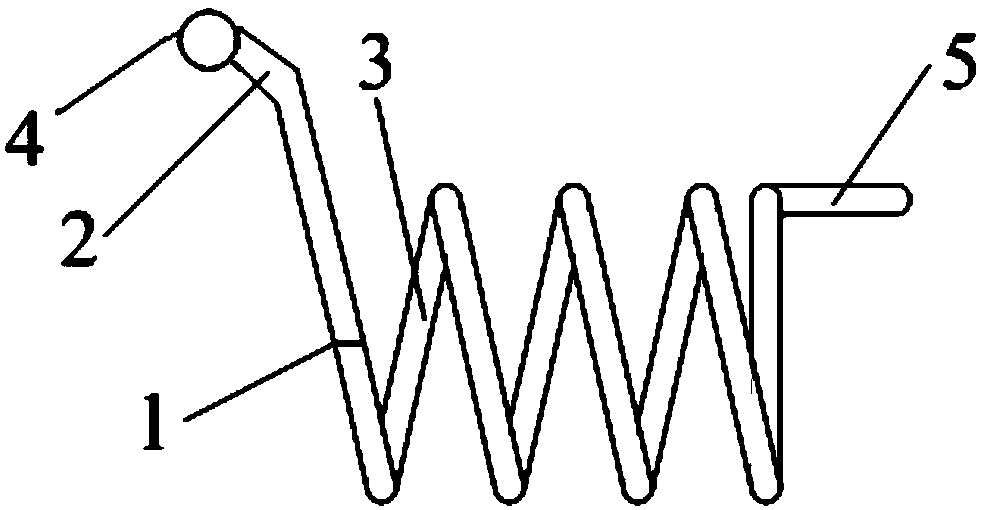

[0044] see figure 2 and image 3 , figure 2 A schematic diagram of the structure of the special-shaped wire anti-vibration hammer anti-slip pre-twisted wire provided by Embodiment 2 of the present invention, image 3 An enlarged view of a solid bead provided as an example of the present invention.

[0045] The difference between the special-shaped non-slip pre-twisted wire provided by the embodiment of the present invention and the first embodiment is that it further includes a solid ball 4 , and the solid ball 4 is arranged at the other end of the support end 2 .

[0046] The purpose of setting the solid ball 4 can better realize the contact between the pre-twisted wire and the outer edge of the anti-vibration hammer, and block the outer surface of the anti-vibration hammer without damaging the wire.

[0047] Optionally, the diameter of the solid ball 4 is 3mm-5mm. The diameter of the solid ball 4 need not be too large, so as to block the anti-vibration hammer.

[0048...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com