Drum-type precision seeder

A precision seeding and drum-type technology, applied in the direction of spaced quantitative seeding machinery, planter parts, etc., can solve the problems of high void rate and double seed rate, inaccurate seeding, easy seed damage, etc., to achieve and Effects of low double particle rate, low void rate, and few failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

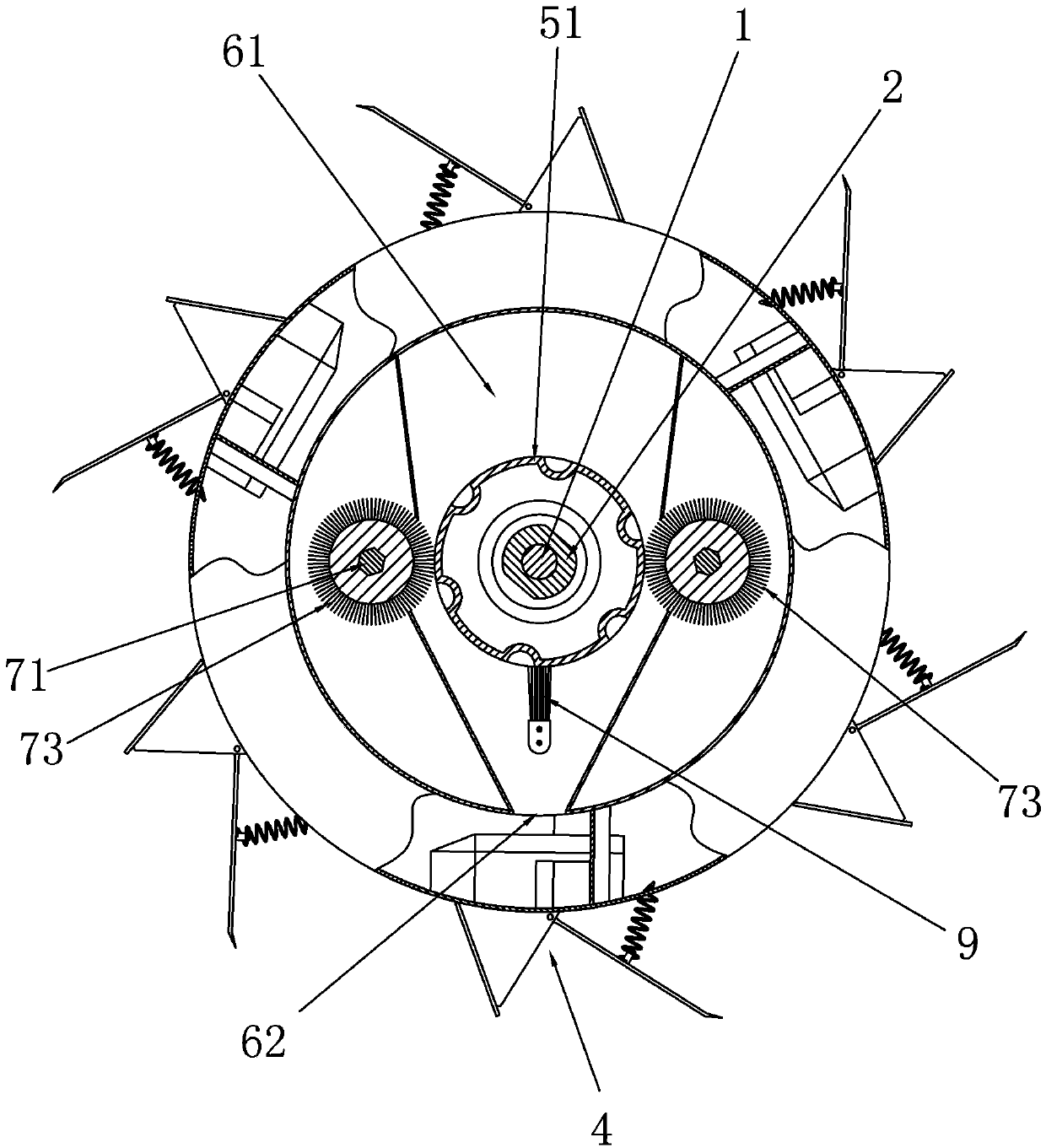

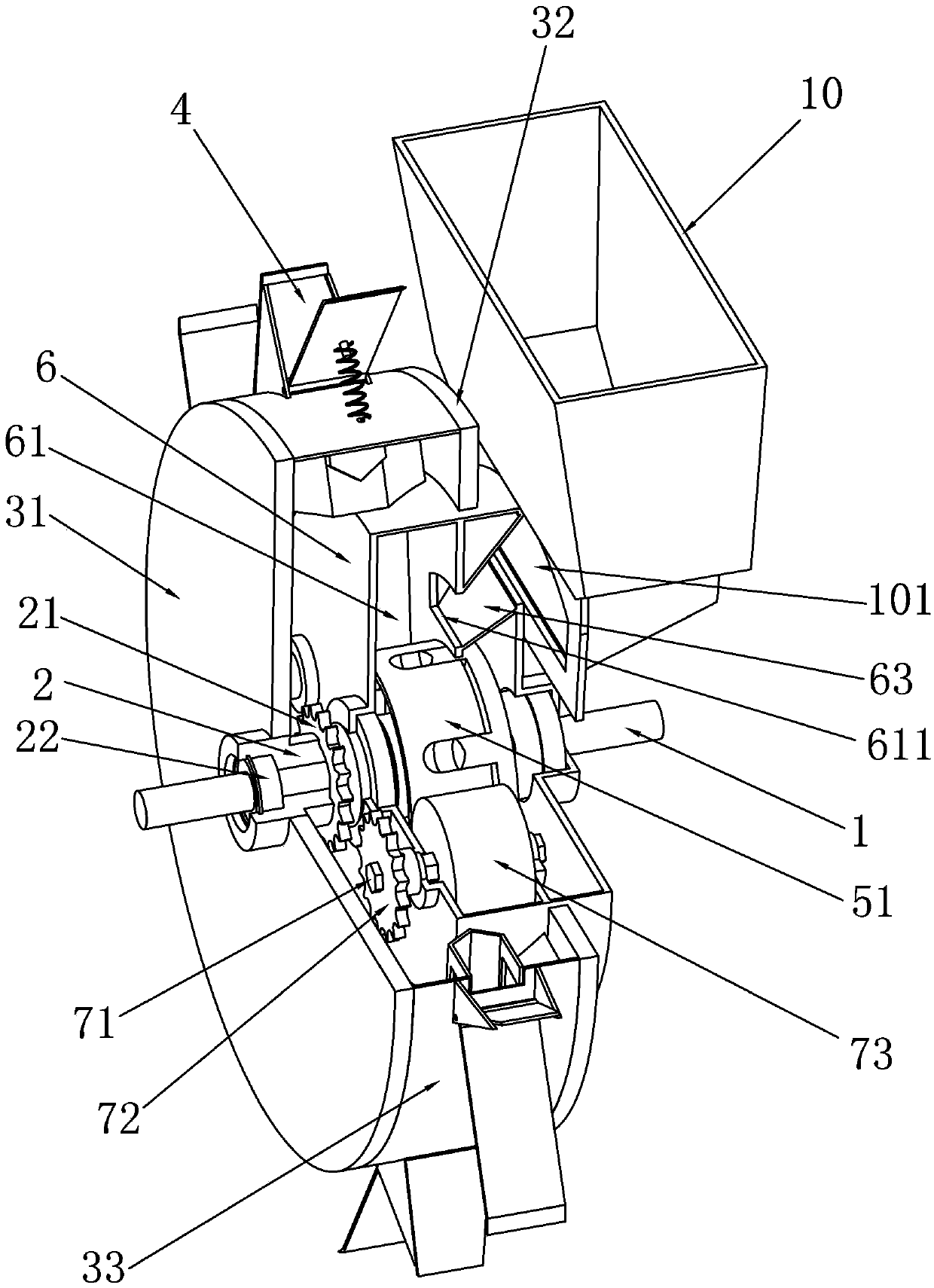

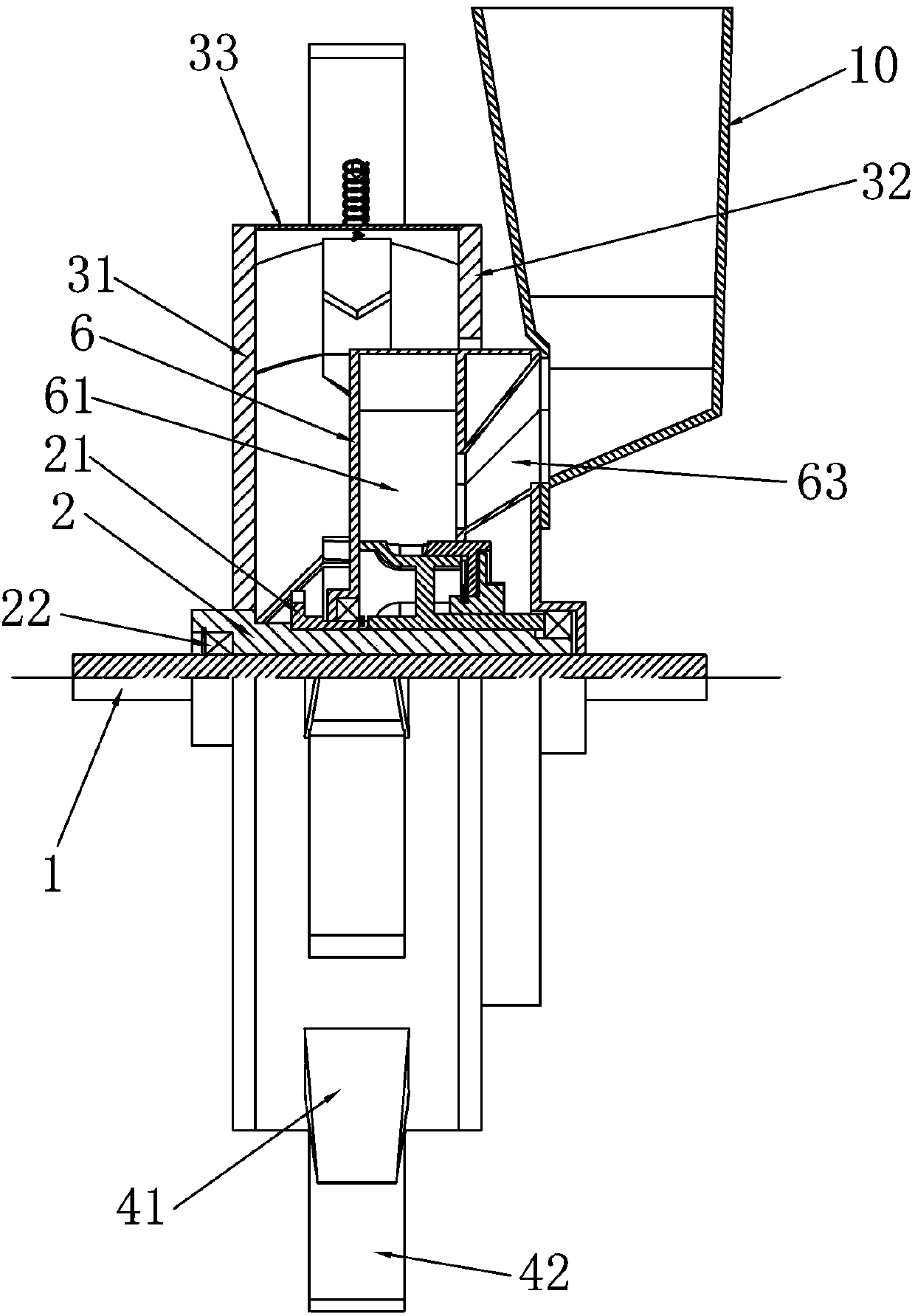

[0038] Such as figure 1 The shown first embodiment of the drum type precision seeder of the present invention includes a central shaft 1, and a sleeve 2 is sleeved on the central shaft 1, see figure 2 with image 3 A bearing 22 is installed in the left end of the sleeve 2, the sleeve 2 can rotate around the central shaft 1, a central sprocket 21 is fixed on the sleeve 2, and the left end of the sleeve 2 is fixedly connected with a first housing 31, and also includes a first housing 31. The second housing 32, the second housing 32 and the first housing 31 are fixedly connected by a cylindrical peripheral wall 33, see figure 1 , The cylindrical peripheral wall 33 is provided with six duckbill holes at equal intervals (the duckbill holes are not shown in the figure), and the cylindrical peripheral wall 33 is provided with a duckbill 4 outside each duckbill hole. The housing 31, the second housing 32 and the cylindrical peripheral wall 33 are all arranged coaxially with the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com