Cavity type plastic toy with adhering lining and manufacturing technology thereof

A production process and adhesive technology, applied in the field of cavity plastic toys and its production process, can solve the problems of low visual impact and low entertainment, to ensure fixed stability, improve visual effects, and increase tensile strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Follow the steps below,

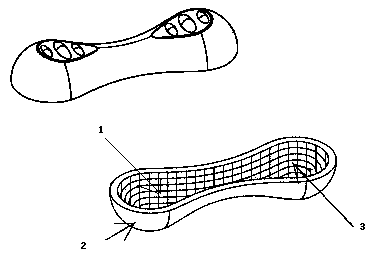

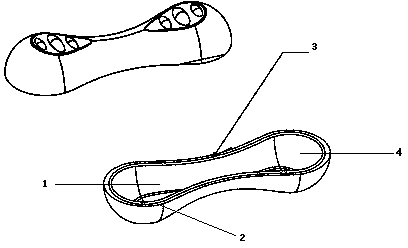

[0049] S1, according to the shape of the cavity-type plastic toy, split it into two half-liners, and make the upper half-liner forming mold and the lower half-liner forming mold respectively;

[0050] S2, take the production of the upper half gallbladder as an example, the upper half gallbladder forming mold can be divided into the upper half gallbladder forming mold positive film, the upper half gallbladder forming mold female mold, and the adhesive lining is placed on the upper half gallbladder forming mold male mold Between the upper half-bladder forming mold female mold, molding at high temperature, shearing, to obtain the adhesive lining base material to be compounded with the same shape as the upper half-bladder;

[0051] The specific temperature for setting the shape is determined according to the basic characteristics of the incoming material and the thickness required by the product. It is based on no deformation within 48 hours after ...

Embodiment 2

[0059] Follow the steps below:

[0060] S1, according to the shape of the cavity-type plastic toy, split it into two half-liners, and make the upper half-liner forming mold and the lower half-liner forming mold respectively;

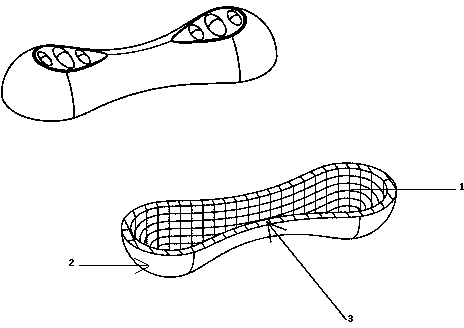

[0061] S2, take the production of the upper half gallbladder as an example, the upper half gallbladder forming mold can be divided into the upper half gallbladder forming mold positive film, the upper half gallbladder forming mold female mold, and the adhesive lining is placed on the upper half gallbladder forming mold male mold Injection molding is directly completed between the female mold of the upper half-bladder forming mold, and the adhesive lining is formed on the inner wall of the upper half-bladder at the same time, and the excess trim is removed by cutting;

[0062] S3, repeating step S2, making the lower half tank with an adhesive lining;

[0063] S4, bonding the edges of the upper and lower half bladders obtained in step S2 and S3 to form a ...

Embodiment 3

[0068] Follow the steps below:

[0069] S1, according to the shape of the cavity-type plastic toy, split it into two half-liners, and make the upper half-liner forming mold and the lower half-liner forming mold respectively;

[0070] S2, take the production of the upper half gallbladder as an example, the upper half gallbladder forming mold can be divided into the upper half gallbladder forming mold positive film, the upper half gallbladder forming mold female mold, and the adhesive lining is placed on the upper half gallbladder forming mold male mold Injection molding is directly completed between the female mold of the upper half-bladder forming mold, and the adhesive lining is formed on the inner wall of the upper half-bladder at the same time, and the excess trim is removed by cutting;

[0071] S3, repeating step S2, making the lower half tank with an adhesive lining;

[0072] S4, bonding the edges of the upper and lower half bladders obtained in step S2 and S3 to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com