Turnover movable coiled material transportation device

A technology of transportation devices and coils, which is applied in the direction of transportation and packaging, transportation of passenger cars, trucks, etc., can solve the problems that cannot meet the needs of loading and transportation of tall and large goods, and achieve the advantages of convenient coil loading and unloading operations, good reliability and good practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

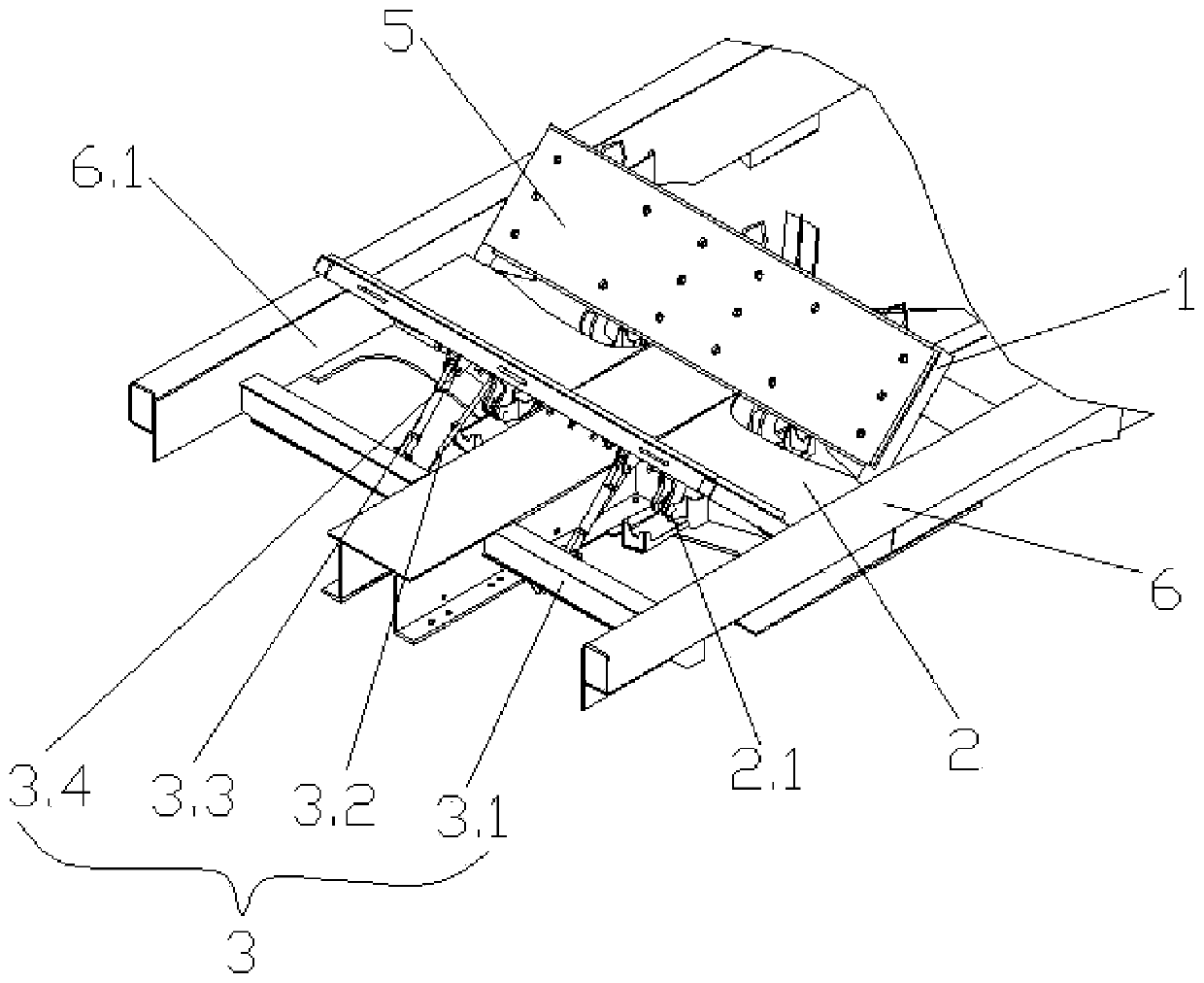

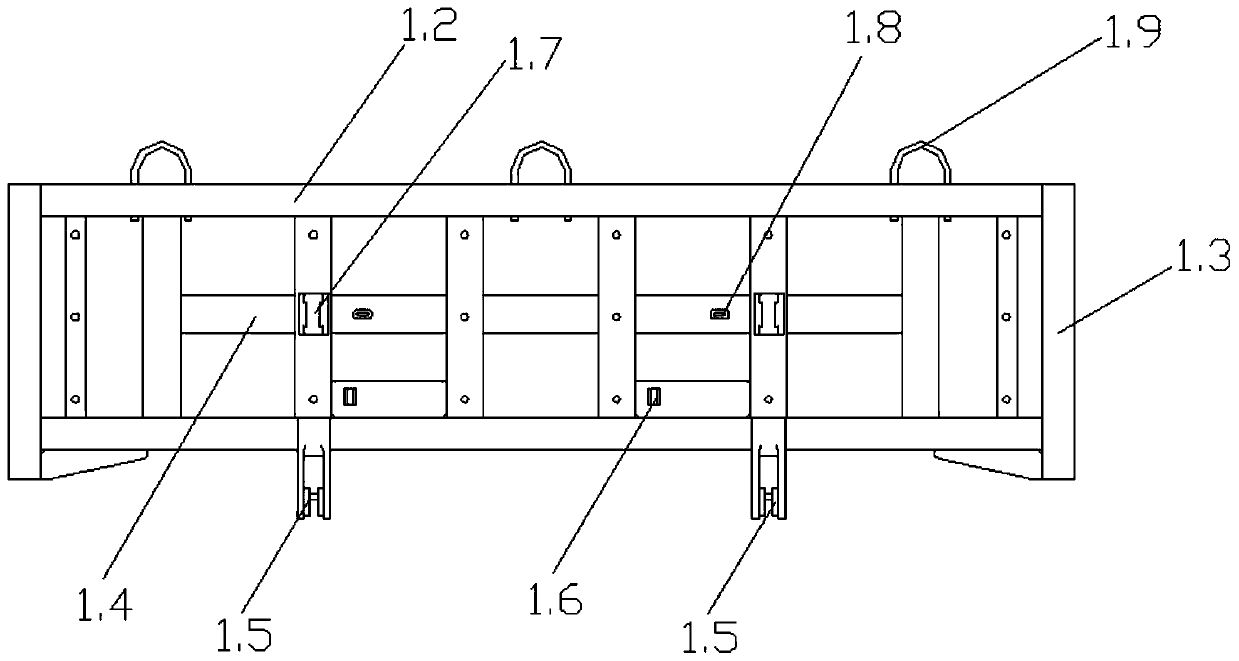

[0039] The embodiment is basically as figure 1 and figure 2 As shown: this embodiment provides a reversible movable coil transportation device, including two bearing frames 1, mounting beams 2 and support mechanisms 3 arranged on both sides of the carrier frame 1, each of the two carrier frames 1 has a supporting surface 1.1; A rubber sheet 5 is laid on the supporting surfaces 1.1 of the two bearing frames 1, and the rubber sheet 5 can be connected to the carrier frame 1 by bonding or fasteners, so that the rubber sheet 5 can be used to contact the coiled material, which can effectively increase the volume of the coiled material. friction with the contact surface, and play the role of flexible buffer to prevent the surface of the plate from being worn; the mounting beam 2 is located at the bottom of the carrier 1, and is used to fix the carrier 1 on the frame 6, and the two carrier 1 It is symmetrically arranged on the installation beam 2 along the length direction of the ve...

Embodiment 2

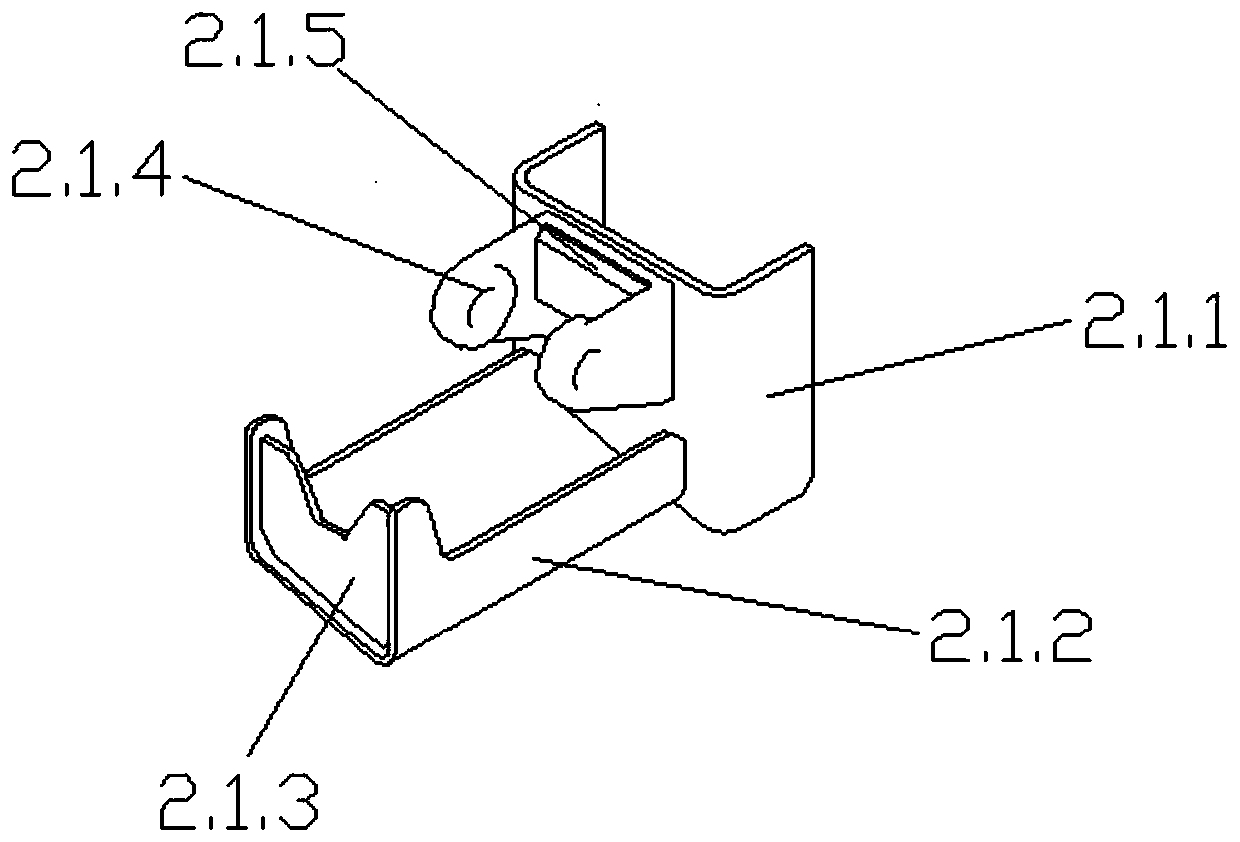

[0048] Embodiment 2 is basically the same as Embodiment 1, the difference is: please combine Figure 6 to Figure 8 As shown, the transportation device provided in this embodiment also includes a lateral stop mechanism 4, which is located on the installation beam 2 in the V-shaped groove; 2, two transverse stop mechanisms 4 can be arranged at a certain distance along the length of the V-shaped groove, which are used to limit and fix the axial ends of the coil respectively, so that the coil is placed horizontally in the V-shaped groove At the same time, it plays an axial positioning role on the coil. In this way, combined with the V-shaped groove structure design, the loaded coil can be fixed in both radial and axial directions. After loading, there is no need to manually set up an additional coil fixing structure, and it can effectively ensure its fixing stability and safety during transportation. It is convenient for coil loading and unloading and can effectively improve its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com