Intelligent heat preservation formwork cast-in-place concrete cavity-free composite wall heat preservation system

A technology of thermal insulation formwork and composite wall, applied in thermal insulation, wall, visible signal device and other directions, can solve the problems of inability to adjust the spacing of wall panels, inability to intelligently warn at night, poor thermal insulation and noise reduction effect, etc., to ensure convenient disassembly and installation The effect of ensuring the stability of fixation and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

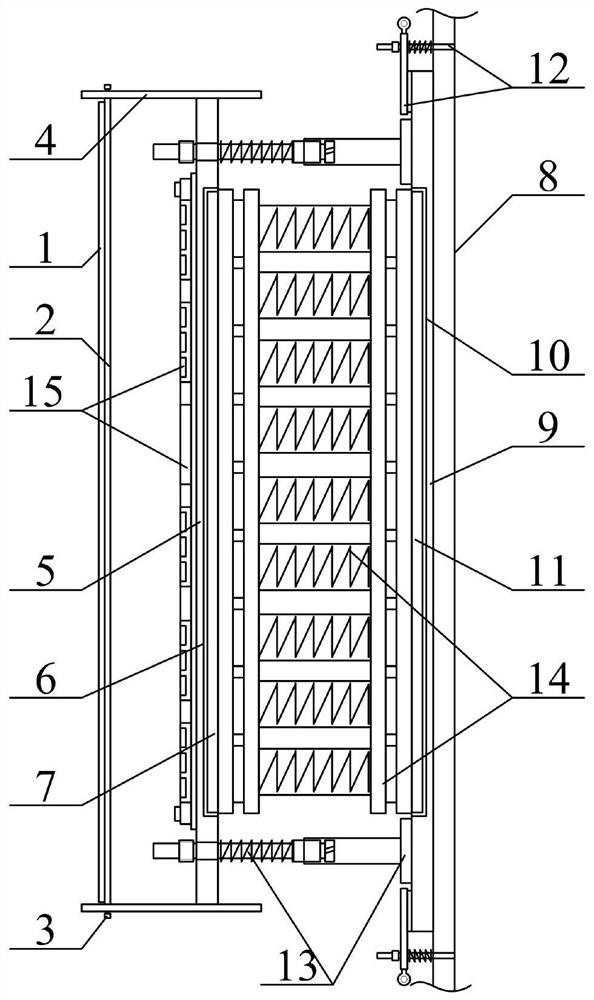

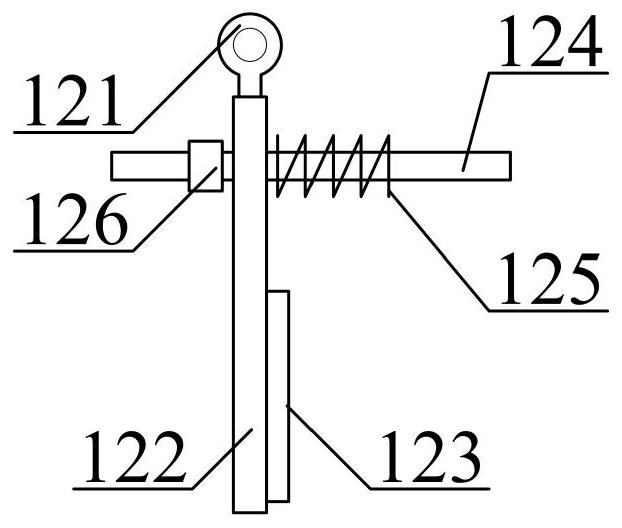

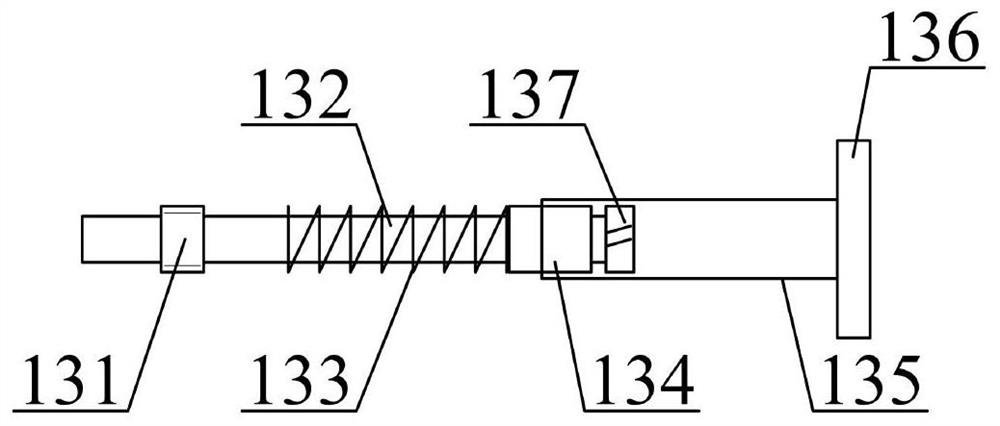

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as appended figure 1 And attached figure 2As shown, the intelligent thermal insulation formwork cast-in-place concrete cavity-free composite wall insulation system includes a transparent plate 1, a light-transmitting plate 2, a fixing bolt 3, an installation guard plate 4, a primary thermal insulation formwork 5, and a primary card slot 6. First-level block 7, building wall 8, second-level insulation formwork 9, second-level card slot 10, second-level block 11, rotary quick-installation clamp structure 12, adjustable spacing support rod structure 13, buffer noise reduction The sound insulation board structure 14 and the intelligent detection auxiliary warning cover structure 15 at night, the transparent board 1 is longitudinally screwed on the left surface of the light-transmitting board 2; The inner left part between them; the horizontal right end bolts of the installation gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com