Multidimensional laser printing device and method capable of manufacturing large-angle cantilever structure workpiece

A technology of multi-dimensional printing and structural parts, which is applied in the direction of improving process efficiency and energy efficiency, and can solve problems such as small forming range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

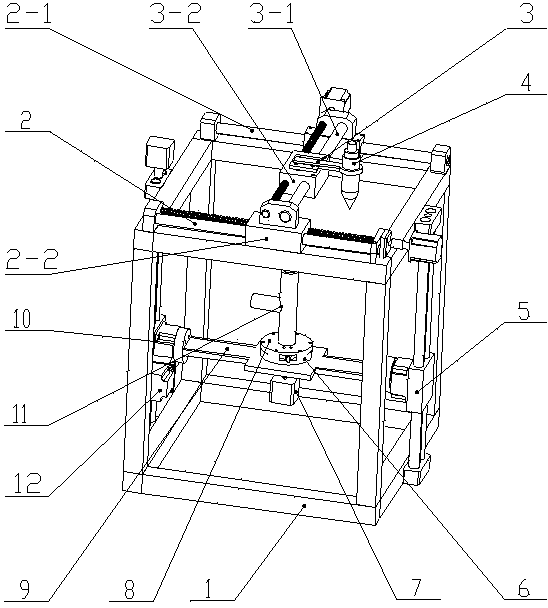

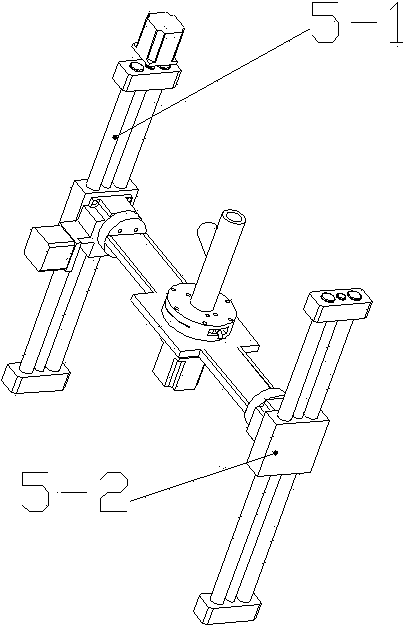

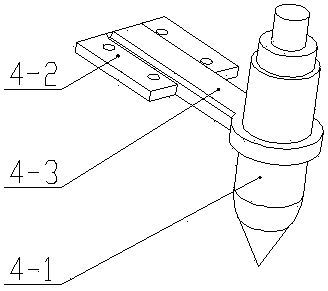

[0033] The present invention is a laser multi-dimensional printing device and method capable of manufacturing large-angle cantilever structural parts. Software technology is used to distinguish the main part and the cantilever part of the workpiece, and the laser cladding head parallel to the Z axis is used to form the main part on the horizontal plane. Two-dimensional scanning and gradually changing the Z axis to complete three-dimensional forming; when forming the cantilever part, use two rotating devices to rotate the cantilever part so that its cross section is parallel to the horizontal plane, and then use the laser cladding head to perform two-dimensional scanning on the horizontal plane and gradually change The Z-axis completes three-dimensional forming, and finally obtains a large-angle cantilever structure workpiece manufactured directly by laser cladding without support.

[0034] The present invention will be further described below in conjunction with the accompanyin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com