Automatic power supply equipment and power supply method for closed track running inspection trolley

A technology for automatic power supply and rail operation, which is applied in the directions of running rail devices, vehicle parts, transportation and packaging, etc. It can solve the problems of complex mechanical structure, affecting the operation of mobile trolleys, and inability to operate, so as to achieve simple and reliable mechanical structure and avoid duplication. The effect of route operation, simple and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with accompanying drawing:

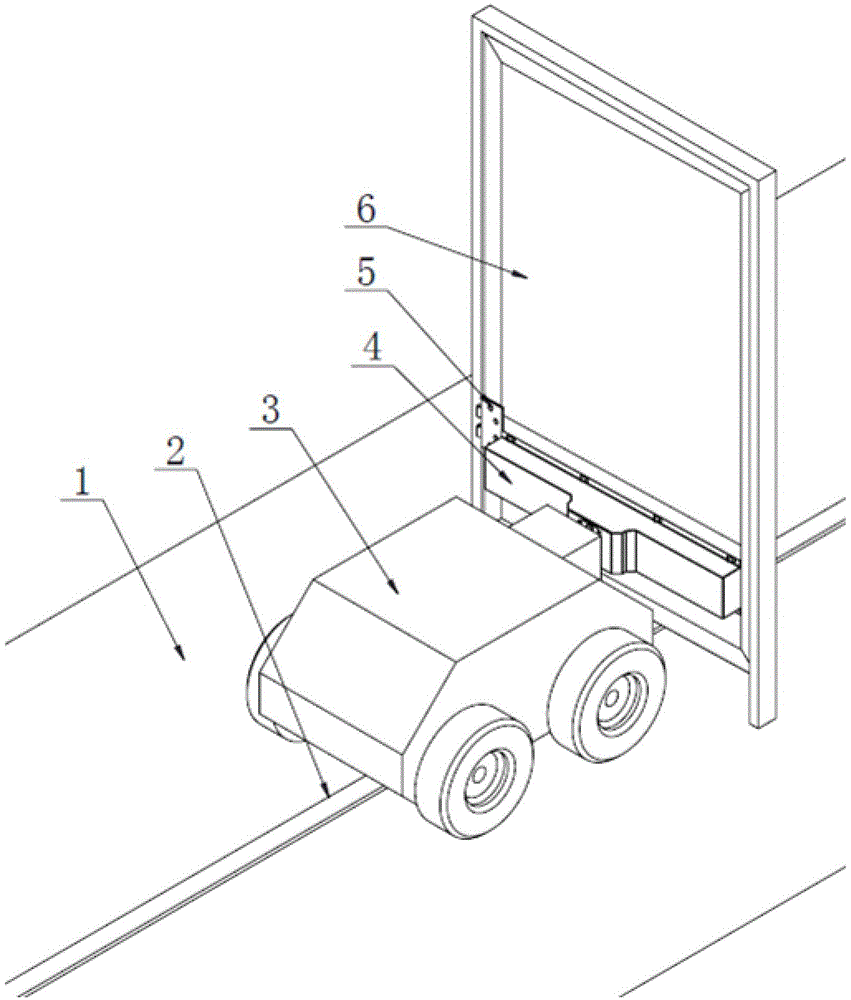

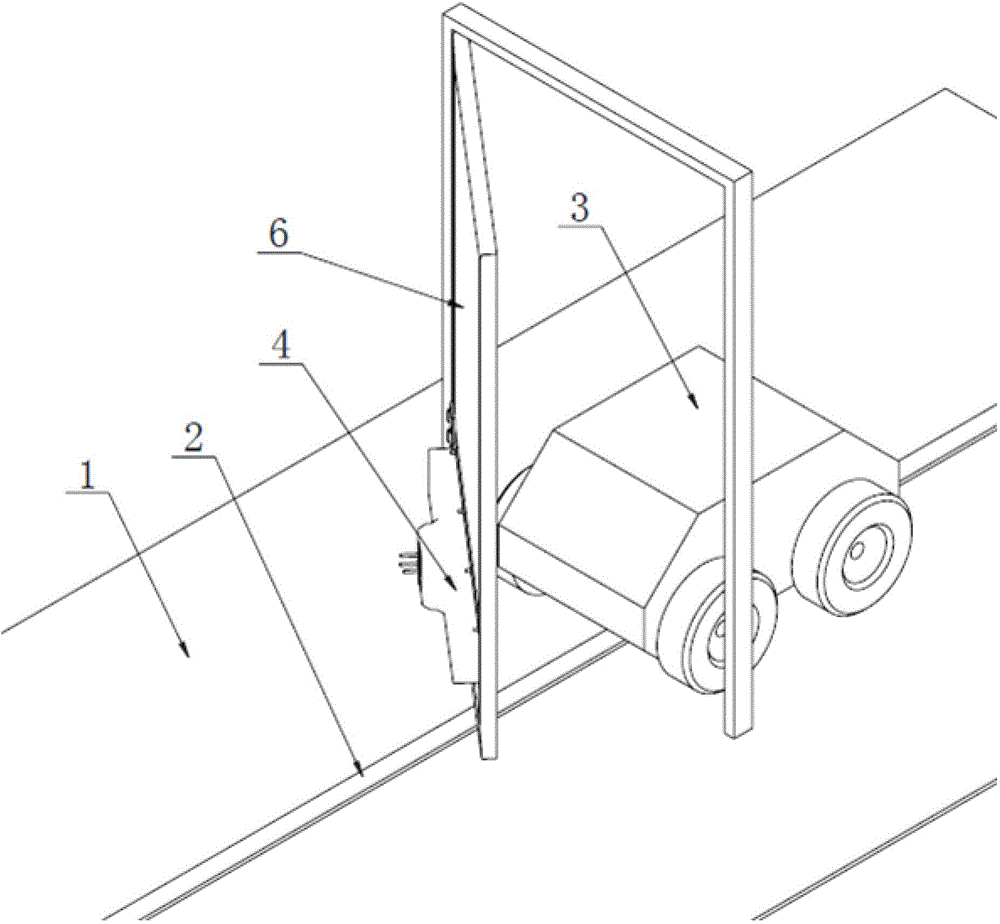

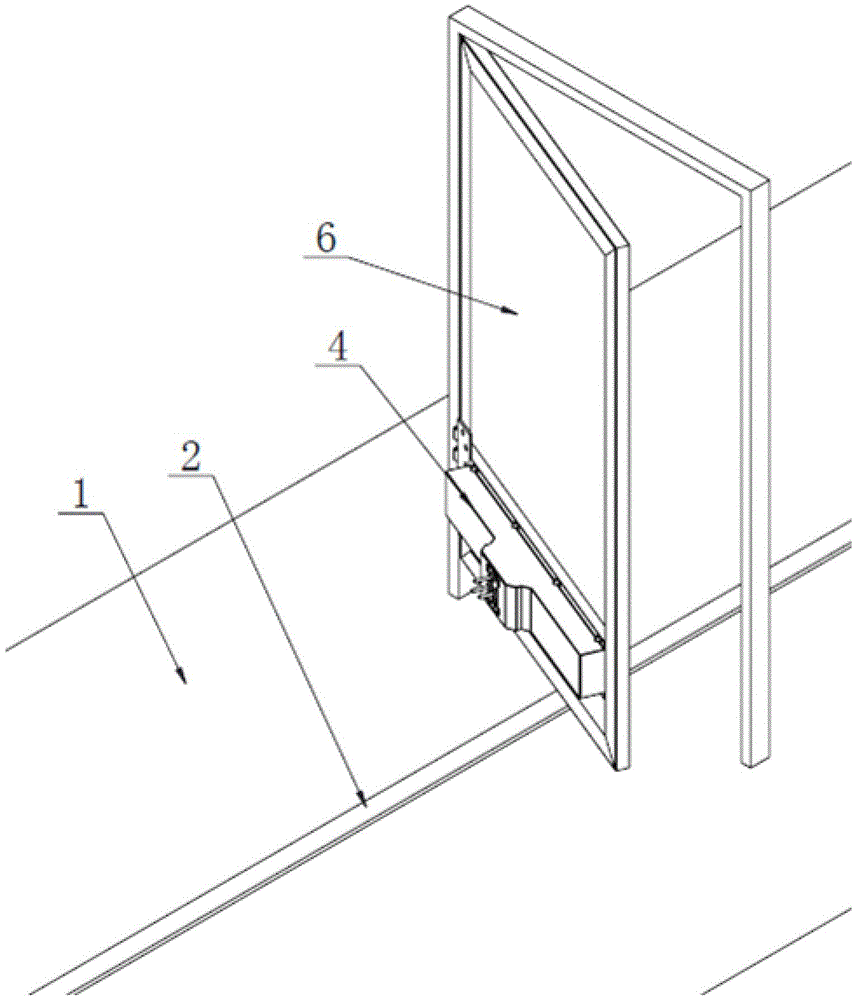

[0027] Such as Figure 1 to Figure 6 As shown: the present invention is an automatic power supply device for a patrol trolley running on a closed track. The navigation rail 2 is laid on the ground 1, and the patrol trolley 3 is placed on the navigation rail 2 and can move along the navigation rail 2. The automatic power supply equipment includes One-way door 6 and automatic door closing device 5, one-way door 6 is arranged on the top of navigation rail 2, the door-opening direction of setting one-way door 6 is the direction from back to front, and the rear end of mobile trolley 3 is equipped with charging plug or Charging socket (4 in the figure represents charging plug or charging socket), and corresponding charging socket or charging plug is installed on the rear side surface of one-way door 6, and automatic door closing device 5 is installed between the facade and door f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap