High-precision standard eccentric shaft with adjustable eccentric distance

An adjustable eccentricity technology, applied in the direction of the eccentric shaft, can solve the problems of difficulty in meeting the accuracy requirements of the eccentricity and finding the highest and lowest points of positive eccentricity, and achieve the effects of simple structure, quick adjustment, and quick measurement and calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

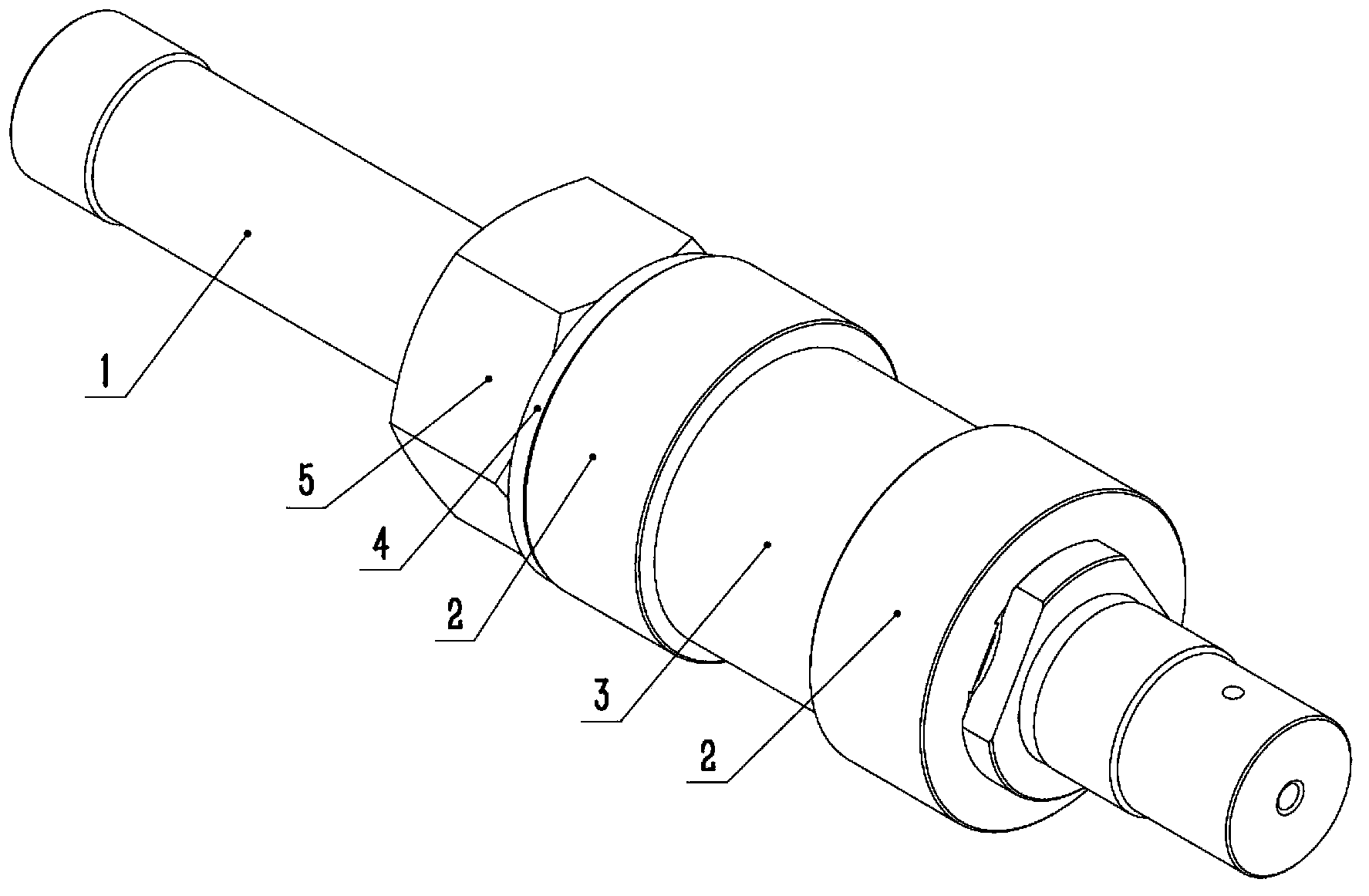

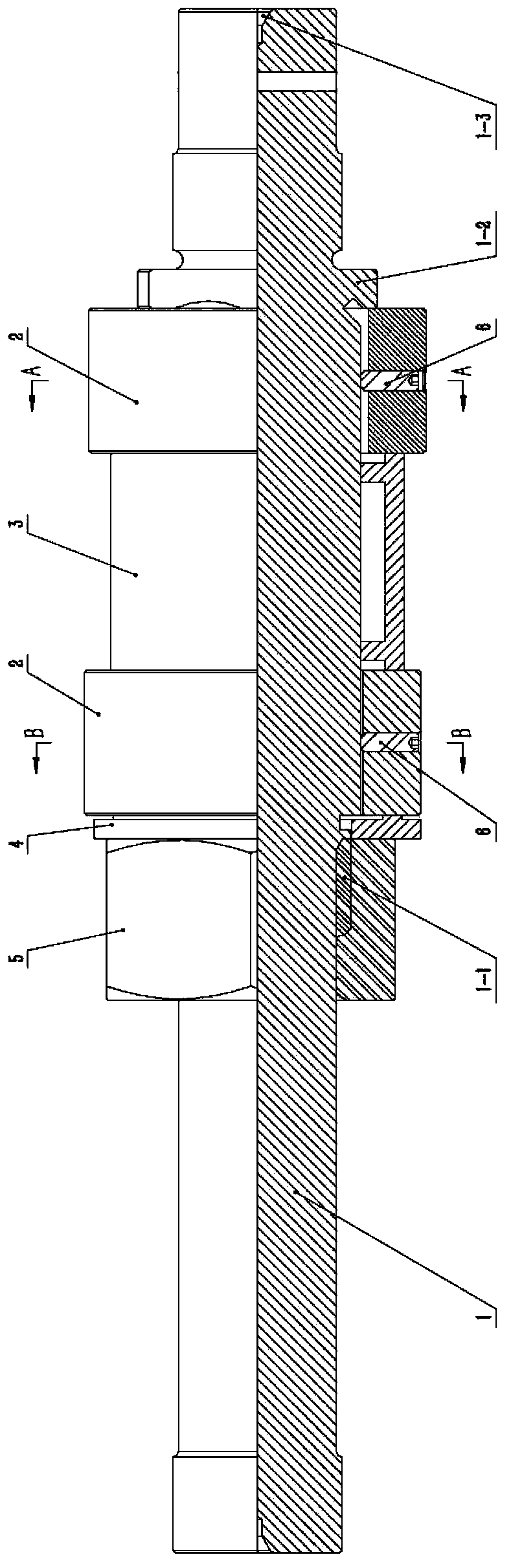

[0016] Such as figure 1 and figure 2 As shown, a high-precision standard eccentric shaft with adjustable eccentricity, which is mainly used for the calibration of crankshaft and camshaft calibration instruments, includes a main shaft 1, one side of the main shaft 1 has an external thread segment 1-1, and the other side has a shaft shoulder 1 -2, there are top holes 1-3 at both ends; the outer thread section 1-2 is set with a washer 4 and a lock nut 5 that can be screwed with the outer thread section;

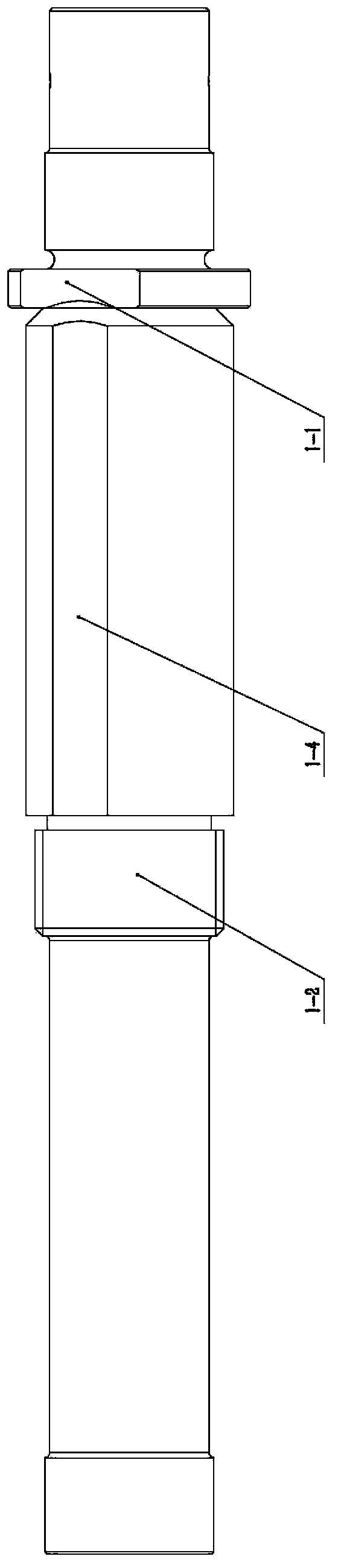

[0017] Spindle 1 is structured as image 3 As shown, there are two slopes 1-4 between the external thread section 1-1 of the main shaft 1 and the shaft shoulder 1-2, and the angle between the slopes 1-4 is 60 degrees, and the distance from the main axis is R mm. Body symmetry.

[0018...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com