Normal temperature debugging system and normal temperature debugging method based on hot-swappable optical module

An optical module and thermal technology, applied in the field of optical communication, can solve the problems of reducing optical power, reducing the production pass-through rate of XFP optical modules, and increasing the cost of optical channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

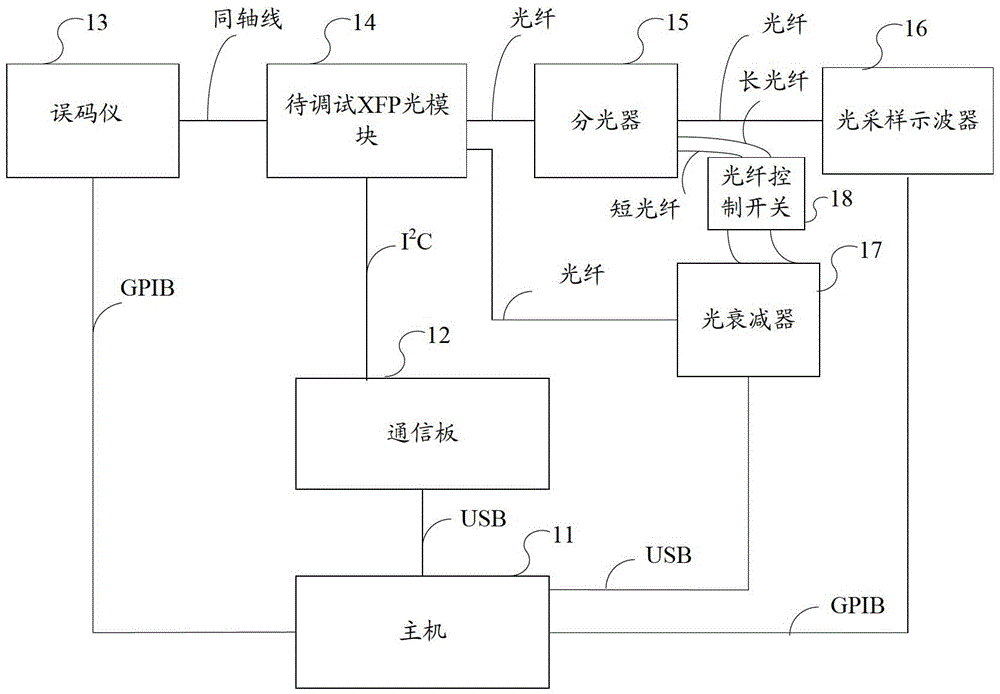

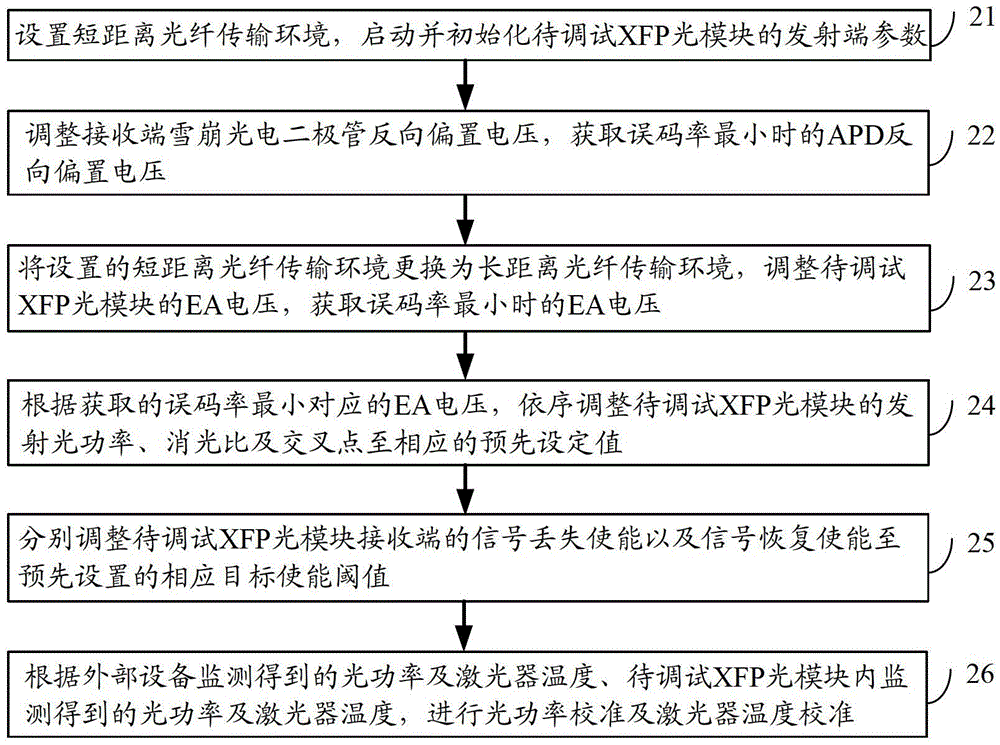

[0073] The technical solutions of the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

[0074] In the prior art, in the normal temperature debugging process, a fixed EA voltage is used or the EA voltage is only adjusted to a point where the extinction ratio is satisfied. After the optical channel cost test fails to meet the standard, the EA voltage value during the normal temperature debugging needs to be changed, and then the entire optical module is adjusted. Re-commissioning and testing, such repeated round trips, will cause a lot of waste of manpower and material resour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com