A process for eliminating micro-short circuits in the production of functional chips by using a megohmmeter

A process method and megohmmeter technology, applied in the direction of circuit, semiconductor/solid-state device testing/measurement, electrical components, etc., can solve problems such as inability to cut with sharp blades, so as to avoid secondary defects, improve pass-through rate, and reduce scrap rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

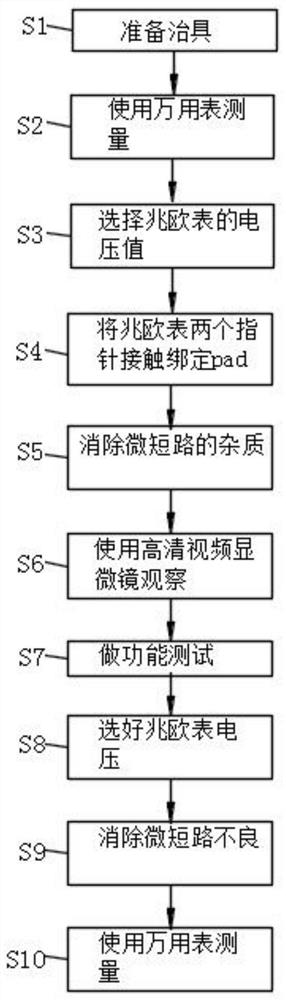

[0029] The invention provides a technical scheme, such as Figure 1 As shown in, a process method for eliminating micro short circuit in the production of functional chips by using a megohmmeter comprises the following specific steps:

[0030] Step 1. Prepare fixture: multimeter, megohmmeter and HD video microscope with m European file. The model of multimeter is victorvc9807a +, the model of megohmmeter is victorvc60b +, and the model of HD video microscope is TTL HK, 15-45 times.

[0031] Step 2. After the silver paste laser etching, use a multimeter to measure and check the silver paste line micro short circuit. The multimeter is adjusted to 200m Ω for measurement. The two pointers contact two adjacent ITO channels. The multimeter shows that it is a micro short circuit if it is greater than 0.1M Ω. The ITO channel is the test channel impedance, which is greater than 0.1M Ω, and it is a micro short circuit between 0 and tens of M Ω.

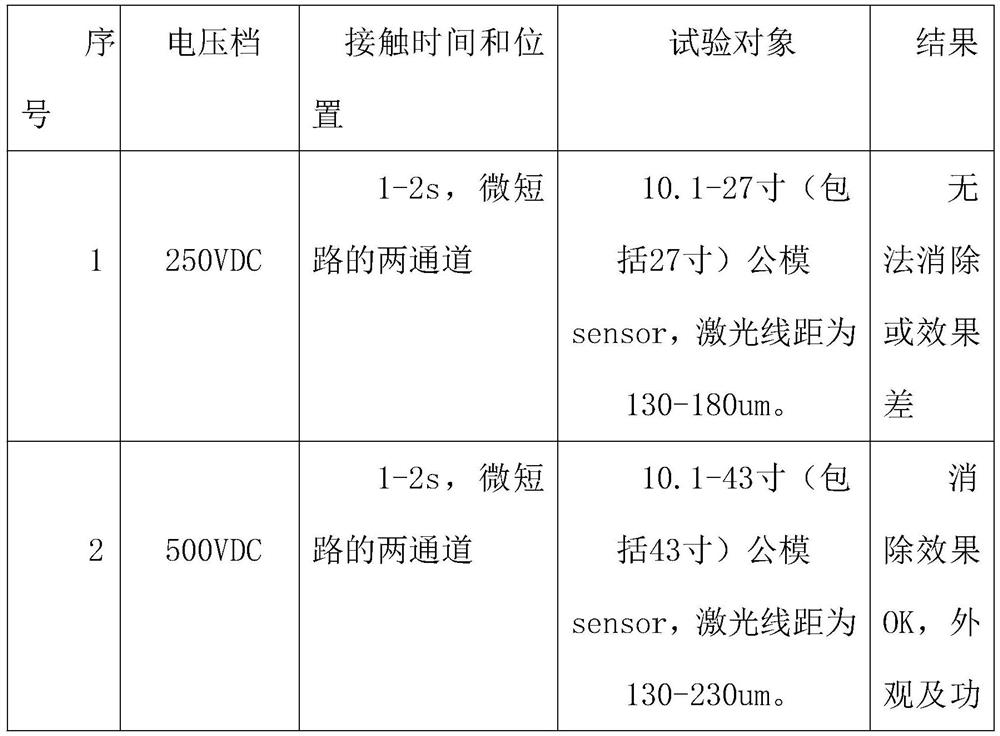

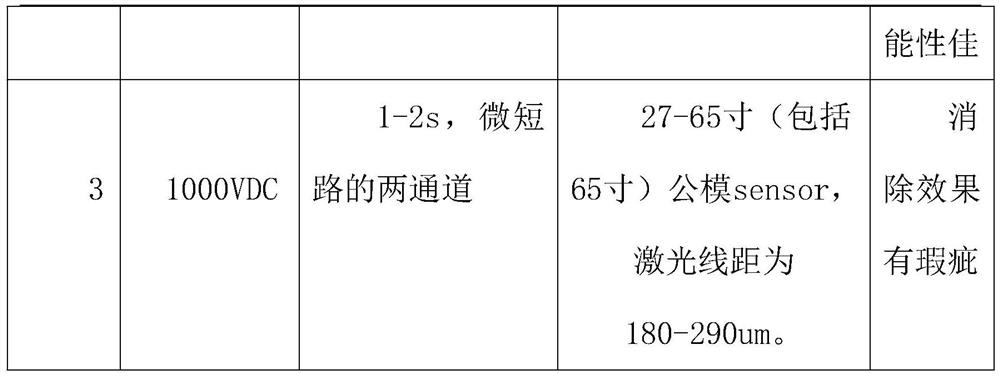

[0032] Step 3: select the voltage value of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com