Short-circuit discharge device for polypropylene film capacitor

A polypropylene film and discharge device technology, applied in the direction of measuring device, measuring electricity, measuring electrical variables, etc., can solve the problems of easily crushed capacitor terminal, uncertain contact state, uneven electrode surface, etc., to achieve reusable High performance, stable contact state and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

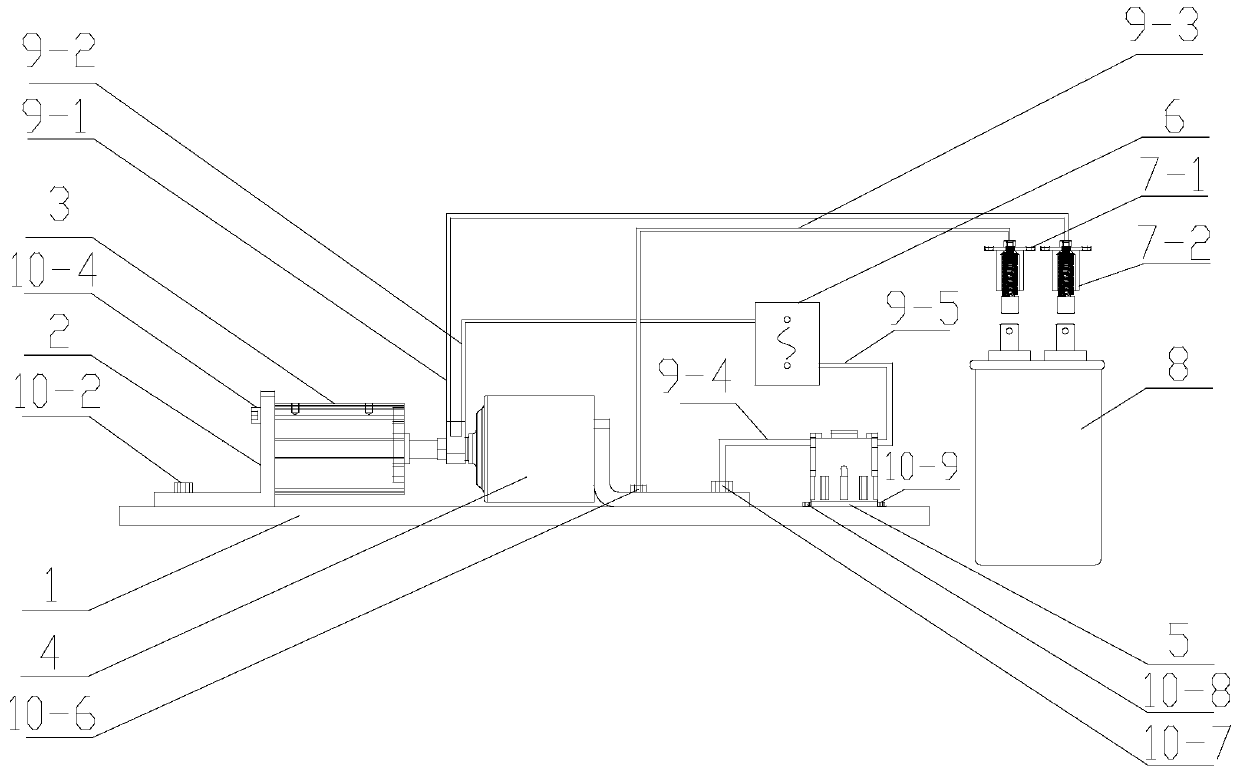

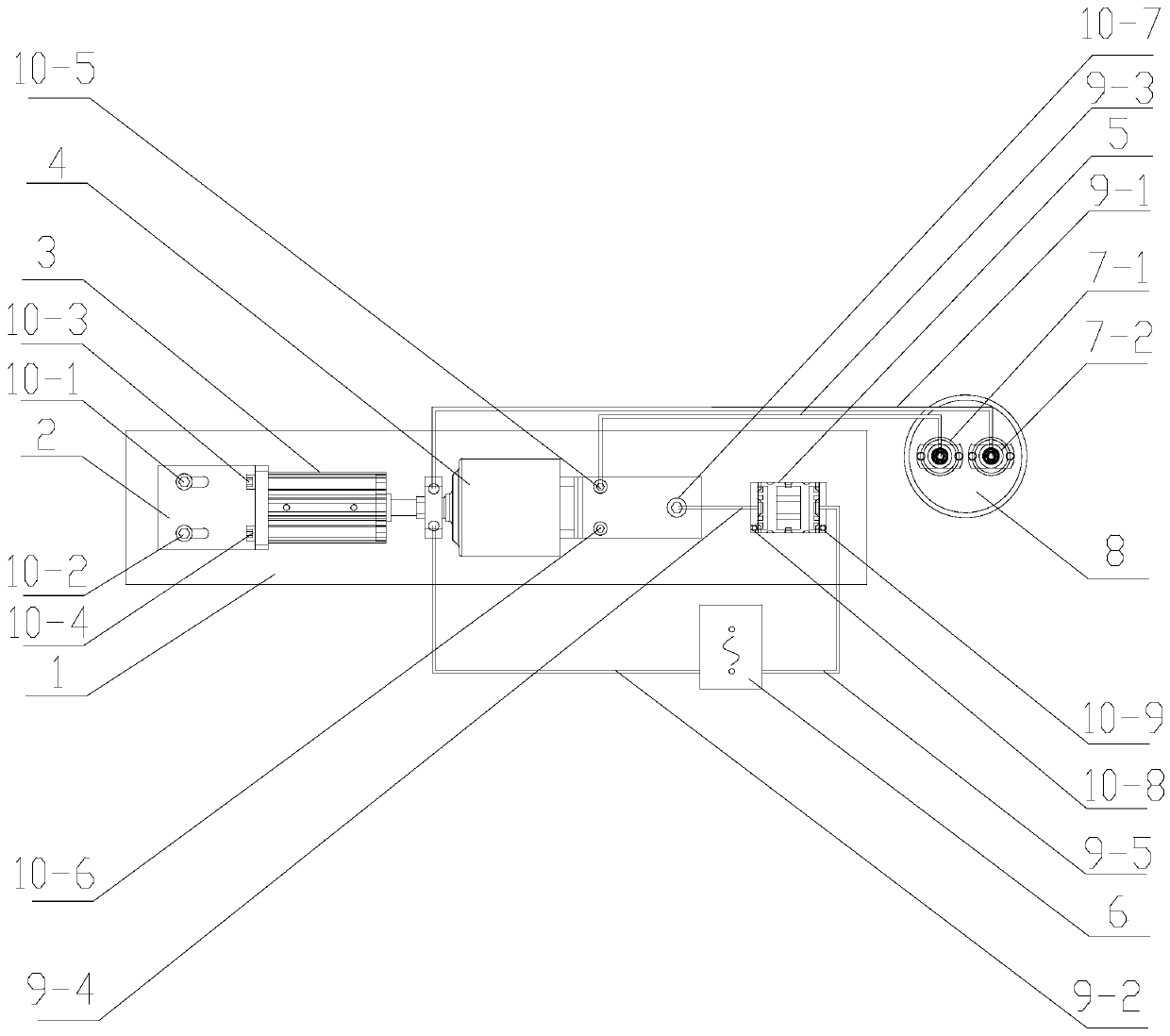

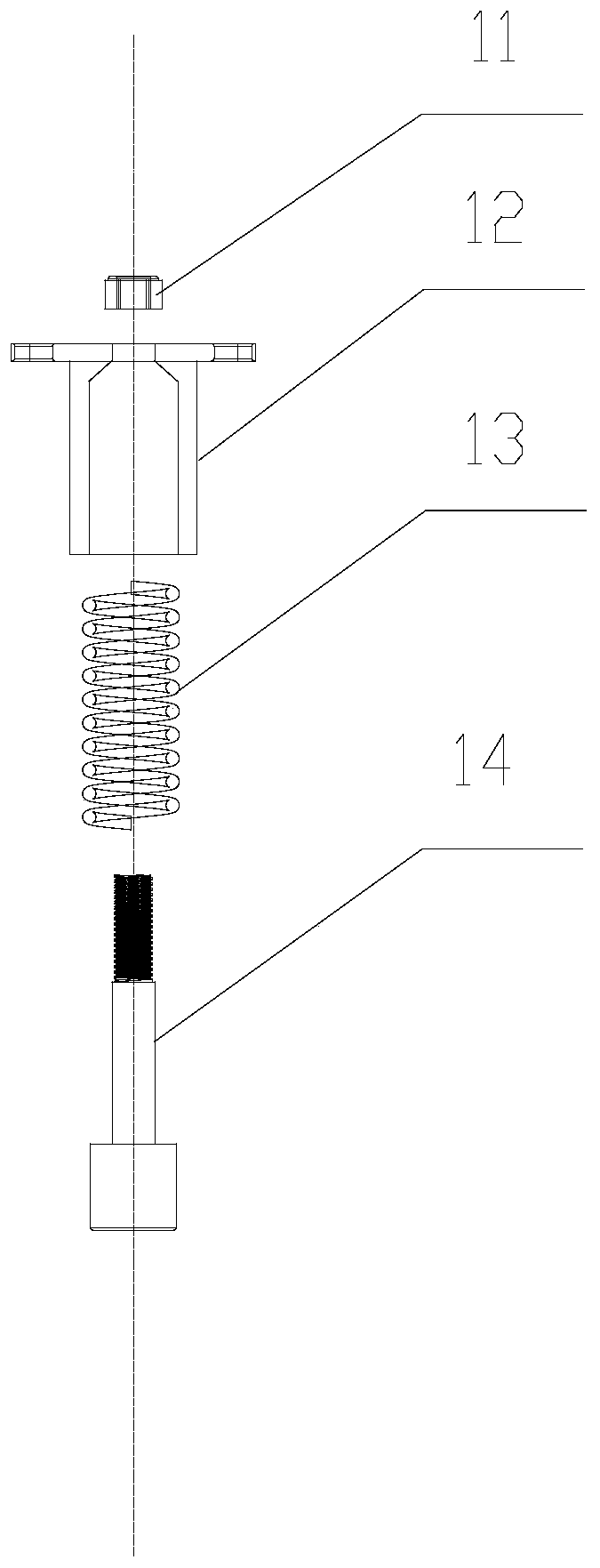

[0020] Figure 1~3 Including base plate 1, fixed bracket 2, cylinder 3, vacuum interrupter 4, AC contactor 5, power supply 6, first contact electrode 7-1, second contact electrode 7-2, capacitor to be measured 8, first Connecting lead 9-1, second connecting lead 9-2, third connecting lead 9-3, fourth connecting lead 9-4, fifth connecting lead 9-5, first fixing nut 10-1, second fixing nut 10-2, the third fixed nut 10-3, the fourth fixed nut 10-4, the fifth fixed nut 10-5, the sixth fixed nut 10-6, the seventh fixed nut 10-7, the eighth fixed nut 10- 8. Ninth fixing nut 10-9, connecting nut 11, fixing casing 12, protection spring 13, electrode tip 14, etc.

[0021] Such as Figure 1~3 As shown, the present invention is a short-circuit discharge device for polypropylene film capacitors, including a base plate 1, the surface of the base plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com