Cooperate with pneumatic workbench to realize circuit board rapid cycle plating fixture

A pneumatic workbench, rapid cycle technology, applied in printed circuits, printed circuit manufacturing, electrical components, etc., can solve problems such as removing splints, product wrinkling and scrapping, etc., to improve production efficiency and improve product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In conjunction with the accompanying drawings, the present invention is described in detail, but the scope of protection of the present invention is not limited to the following examples, that is, all simple equivalent changes and modifications made with the patent scope of the present invention and the content of the specification are still patents of the present invention. covered.

[0025] In this embodiment, the jig for fast cycle electroplating of circuit boards is realized by cooperating with the pneumatic workbench. The pneumatic workbench (not shown in the figure) includes a stepping device and a work surface:

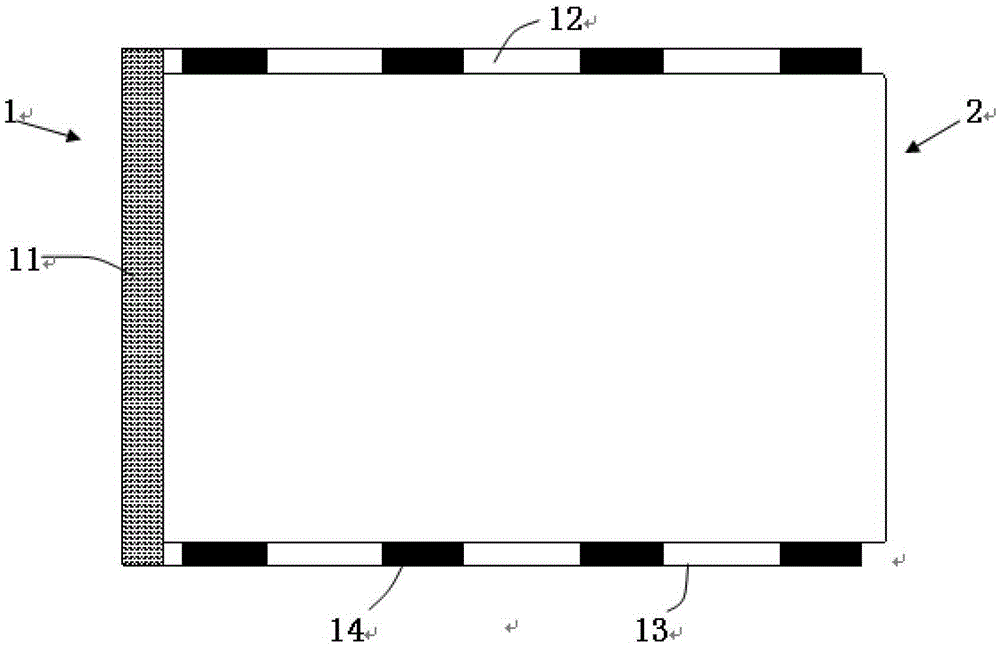

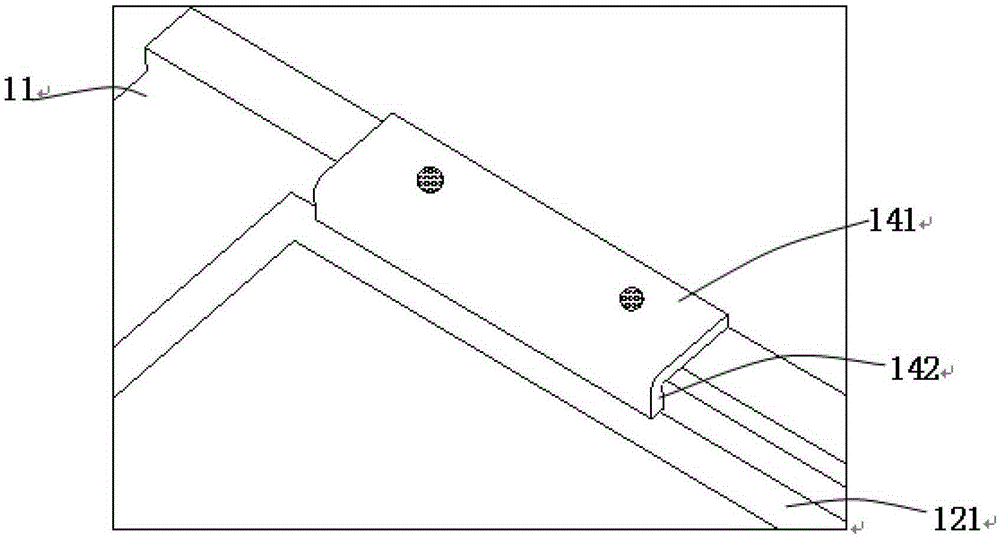

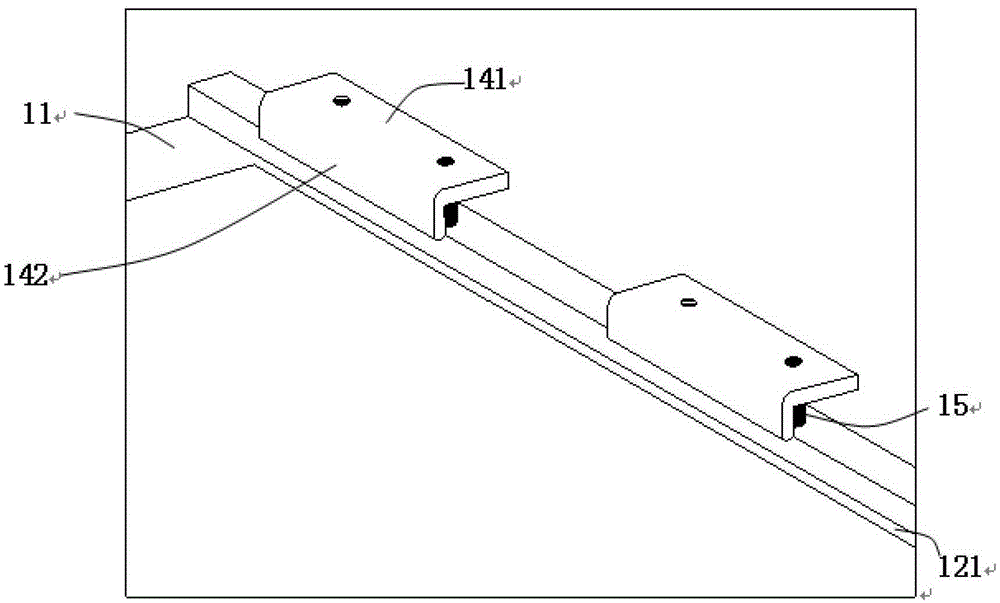

[0026] The working surface is provided with grooves (not shown) that are used to cooperate with the layout of the clamps, and the clamps can be fixed on the working surface through the grooves. The clamps are a frame 1 that matches the specifications of the circuit board 2. The size of the frame 1 can be According to the size setting of the circuit board...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com