Sugarcane harvest machine cutting conveying system with strong feeding capacity

A technology for harvesting machinery and conveying systems, applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of increased vibration of the cutting system, high rate of sugarcane head breakage, and blockage, so as to prevent accumulation blockage, increase Effect of roller pitch and improvement of conveying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

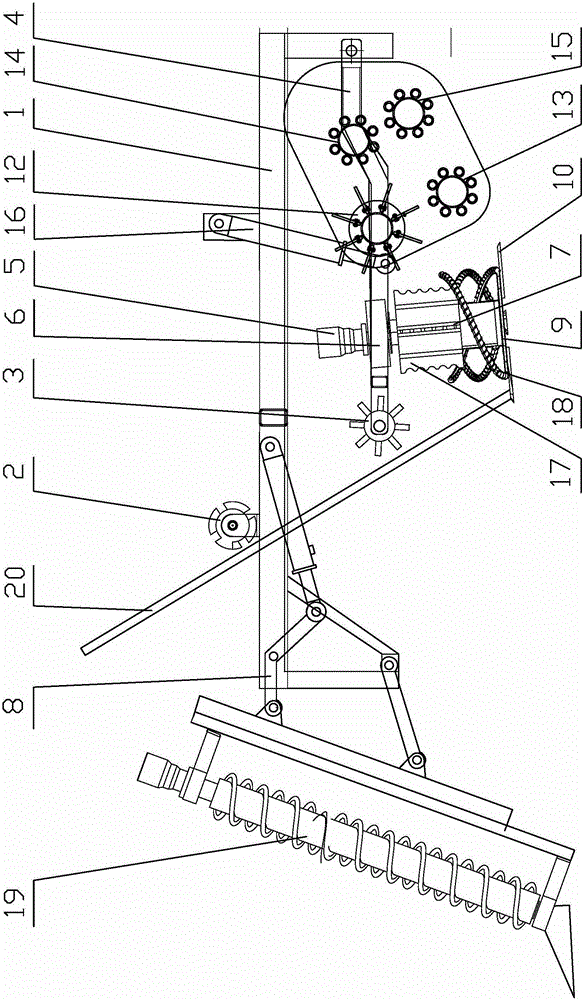

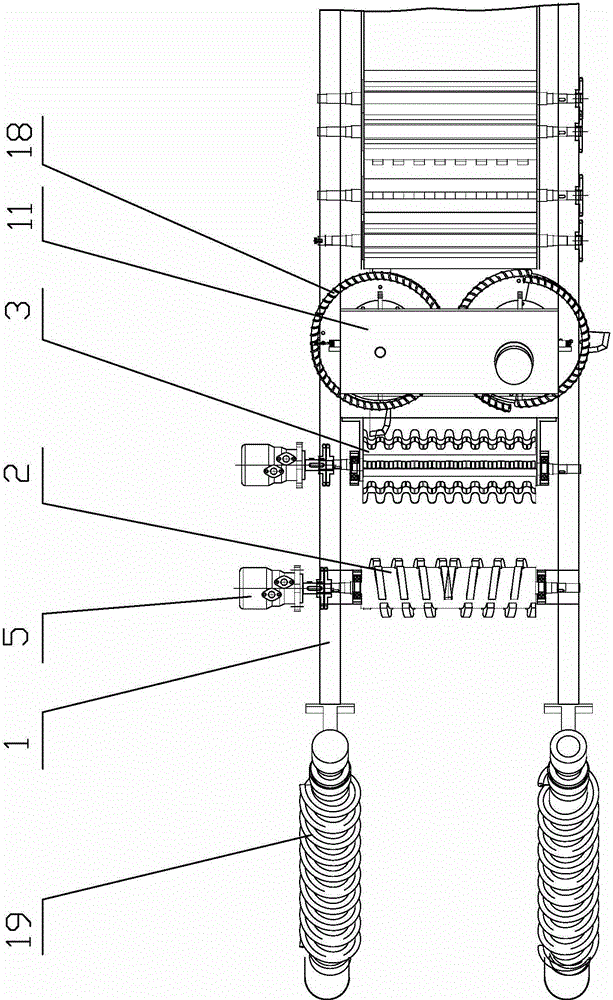

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] The sugarcane harvesting machinery cutting and conveying system with strong feeding capacity of the present invention includes a cane pressing device, a cutting device and a feeding device arranged sequentially from front to back. After the cane-supporting roller 19 is installed on the longitudinal beam front end of the frame 1 by the cane-supporting frame 8), the feeding device is followed by a stripping and cutting device installed on the frame 1, and the cutting device and the feeding device Installed on the cutting frame 4, the tail end of the cutting frame 4 is hinged with the vertical beam at the rear end of the frame 1, and the middle part of the cutting frame 4 is connected to the longitudinal beam of the frame 1 through an oblique lifting cylinder 16, specifically the piston of the lifting cylinder 16 The bar hinges the cutting...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap