Mashed tea beverage and production process thereof

A process and beverage technology, applied in the field of Leicha beverage and its production process, can solve the problems of insufficient health care function, obvious stratification, poor taste of salt, etc., and achieve the effect of improving the value of diet therapy, enhancing anti-virus, and preventing coronary heart disease.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

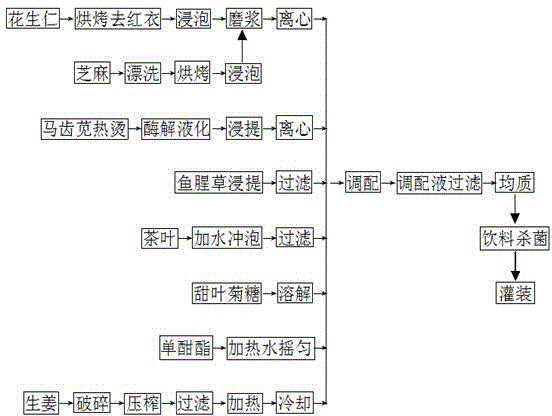

Image

Examples

Embodiment 1

[0042] To make 500kg of Lei Cha beverage, the specific formula is: mung bean 12kg; peanut 10kg; sesame 5kg; tea leaves 0.2kg; ginger 0.6kg; houttuynia cordata 2kg; purslane 1kg; stevia 0.1kg; Monoglyceride 0.2kg; D-sodium erythorbate 0.05kg; citric acid 0.5kg, the rest is water.

[0043] The technique of making above-mentioned lei cha beverage, concrete steps are as follows:

[0044] (1) Put the peanuts and sesame seeds in the oven, bake them at 155°C for about 20 minutes, put the peanut kernels without the red coat in the water containing soda, soak for 8 hours, and soak the sesame seeds in the water for 2.5 hours; The soaked peanuts and sesame are mixed, then defibrified, and then a suitable centrifuge is selected for centrifugation to obtain a sesame and peanut slurry.

[0045] (2) Blanch the purslane with hot water at 90°C that is 4 times the weight of the purslane, then liquefy it with pectin enzymatic hydrolysis for 10 minutes, and then extract it in a solvent with a pH...

Embodiment 2

[0055] A lei tea beverage, the formula according to weight percentage is: mung bean: 1.0%; peanut: 1%; ginger: 0.04%; sesame: 0.1%; tea: 0.02%; houttuynia cordata: 0.05%; 0.05%; stevioside: 0.01%; monoglyceride: 0.02%; sodium D-isoascorbate: 0.01%; citric acid: 0.05%; water: the balance.

[0056] The technique of making above-mentioned lei cha beverage, concrete steps are as follows:

[0057] (1) Put the peanuts and sesame seeds in the oven, bake them at 150°C for about 20 minutes, put the peanut kernels without the red coat in the water containing soda, soak for 8 hours, and soak the sesame seeds in the water for 2 hours; The soaked peanuts and sesame are mixed, then defibrified, and then a suitable centrifuge is selected for centrifugation to obtain a sesame and peanut slurry.

[0058] (2) Blanch the purslane with hot water at 85°C that is 4 times the weight of the purslane, then liquefy it with pectin enzymatic hydrolysis for 10 minutes, and then extract it in a solvent wi...

Embodiment 3

[0068] A lei tea beverage, the formula according to weight percentage comprises: mung bean: 3.0%; peanut: 3.0%; ginger: 0.15%; sesame: 1.5%; tea: 0.1%; houttuynia cordata: 1%; 0.5%; stevia sugar: 0.03%; monoglyceride: 0.05%; sodium D-isoascorbate: 0.015%; citric acid: 0.15%; water: the balance.

[0069] The technique of making above-mentioned lei cha beverage, concrete steps are as follows:

[0070] (1) Put the peanuts and sesame seeds in the oven, bake them at 160°C for about 20 minutes, put the peanut kernels without the red coat in water containing soda, soak for 8 hours, and soak the sesame seeds in water for 3 hours; The soaked peanuts and sesame are mixed, then defibrified, and then a suitable centrifuge is selected for centrifugation to obtain a sesame and peanut slurry.

[0071] (2) Blanch the purslane with hot water at 85-95°C that is 4 times the weight of the purslane, then liquefy it with pectin enzymatic hydrolysis for 10 minutes, and then extract it in a solvent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com