A deburring mechanism and method for a flux-cored steel strip

A steel strip and flux core technology, applied in turning equipment, tool holder accessories, metal processing equipment, etc., can solve the problems of irregular wire drawing die service life, lax seam, reduction, etc., to improve wire drawing die life, Simple and practical effect processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

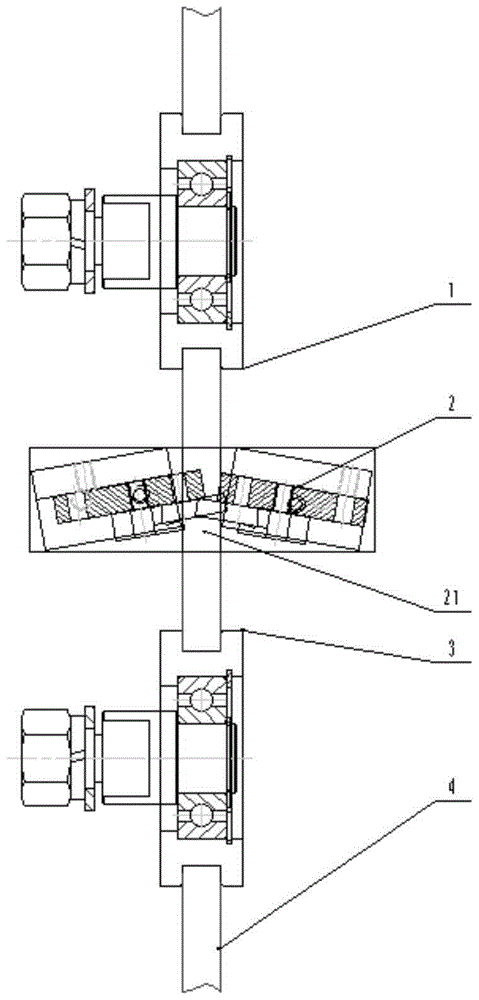

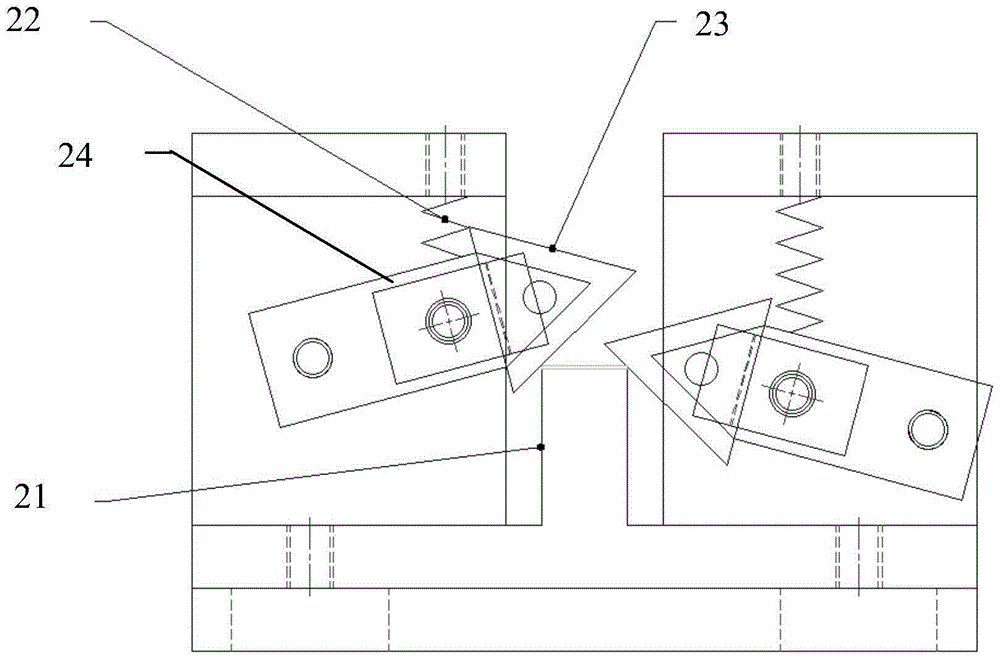

[0017] Such as figure 1 As shown, the mechanism for deburring the flux-cored steel strip provided by the present invention is characterized in that it includes a front guide wheel part (1), a rear guide wheel part (3) and a front guide wheel part (1), a rear guide wheel part ( 3) Between the scraping part (2), the scraping part (2) includes a cutter head assembly, and a steel belt support (21) arranged at the lower part of the cutter head assembly, and one end of the steel belt support (21) is connected The other end of the front guide wheel part (1) is connected to the rear guide wheel part (3). The beneficial effect of adopting this structure is that the cut cored steel strip is placed on the steel strip support (21), after being positioned by the front guide wheel part (1), it enters the scraping part (2) for deburring, and then passes through The rear guide wheel part (3) is positioned for subsequent processing, and the deburring of the flux-cored steel strip (4) is more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com