Major-diameter airframe test loading clamp

An aircraft fuselage, large-diameter technology, applied in the field of large-diameter aircraft fuselage test loading fixtures, can solve problems such as constraints, and achieve the effect of ensuring rationality, good constraints, and convenient weighting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

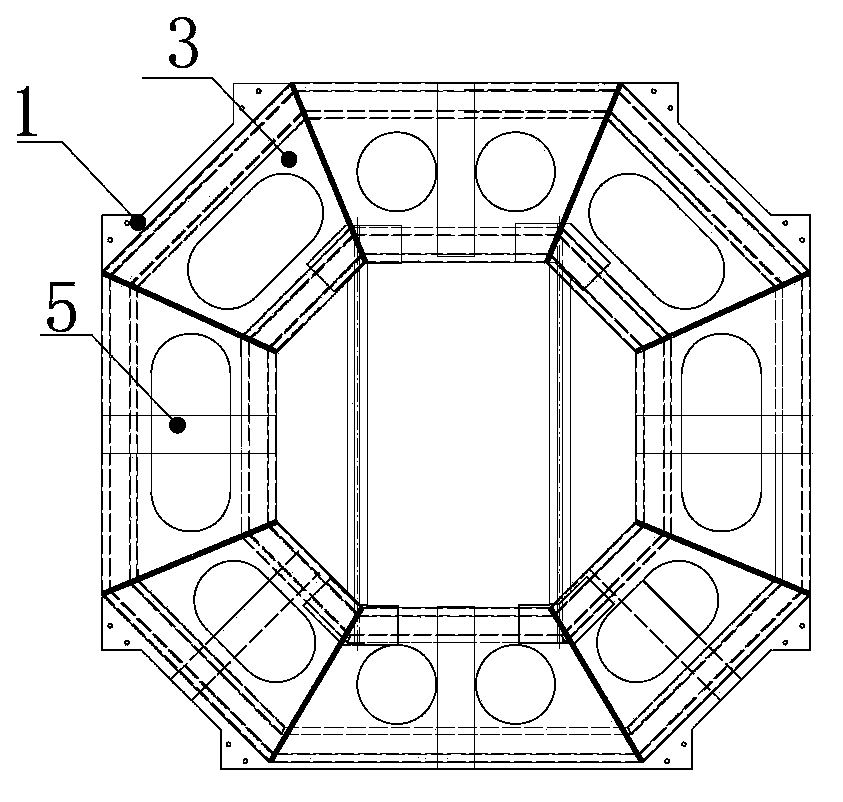

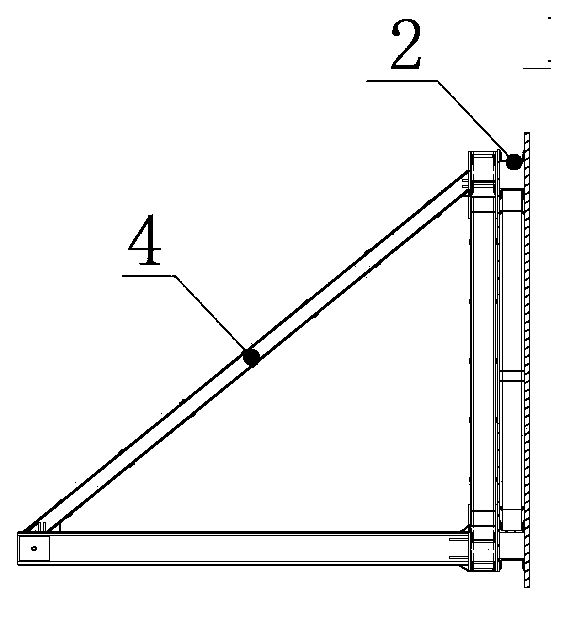

[0018] see figure 1 , The large-diameter aircraft fuselage test loading fixture of the present invention includes a butt end plate, a uniform force ring, a skin, a triangular beam, and a loading beam. The butt end plate is a ring structure matching the transition section of the fuselage, and the uniform force ring surrounds the inner and outer rings of the butt end plate. One side of the equal force ring is connected to the butt end plate, and the other side is connected through the skin to apply a concentrated load. Load the device.

[0019] Among them, the structural design features and functions of each component are as follows:

[0020] Butt-joint end plate—design according to the size of the butt-joint end frame of the test piece. The center ring of the butt-joint end plate is the butt-joint ring that is docked with the butt joint bolts of the test piece. The force...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com