Limp home oil system for CVT with wet clutch

A technology of continuously variable transmission and wet clutch, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc. It can solve the problems of inability to transmit power, inconvenience for users, and inability to return to the repair shop with its own power, so as to achieve reliability And the effect of improved robustness and good inheritance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

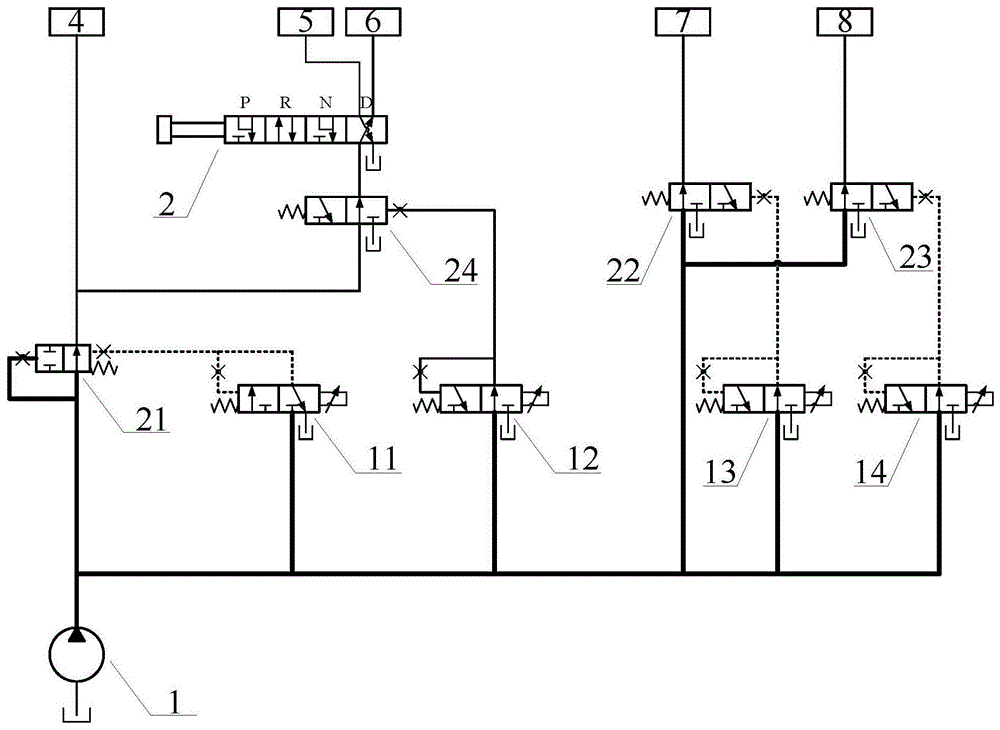

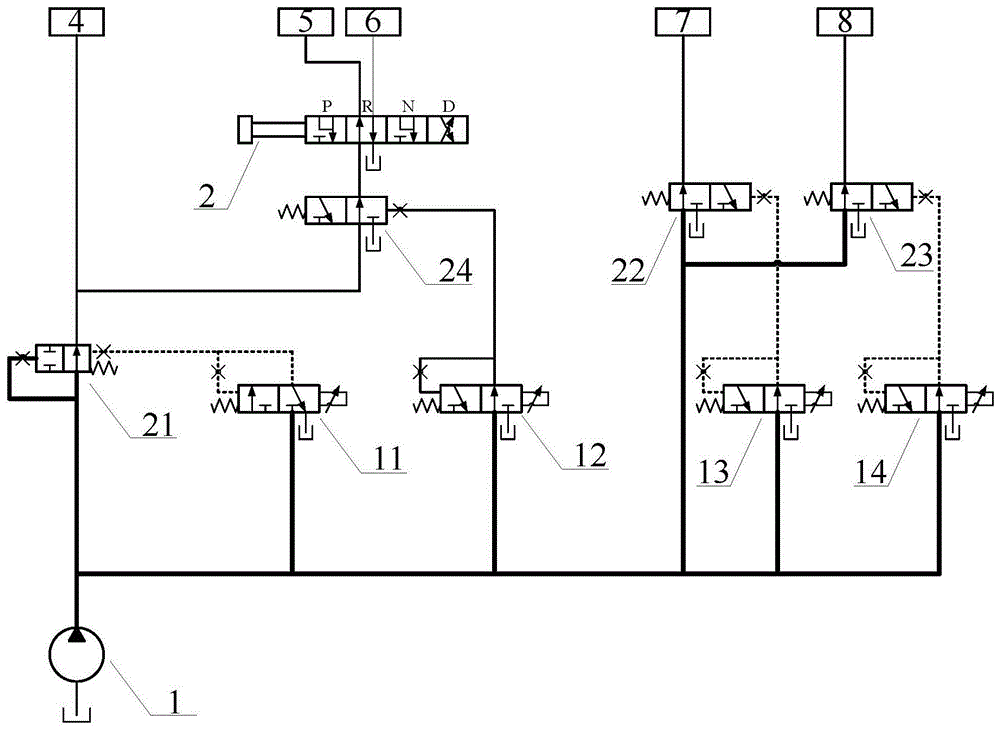

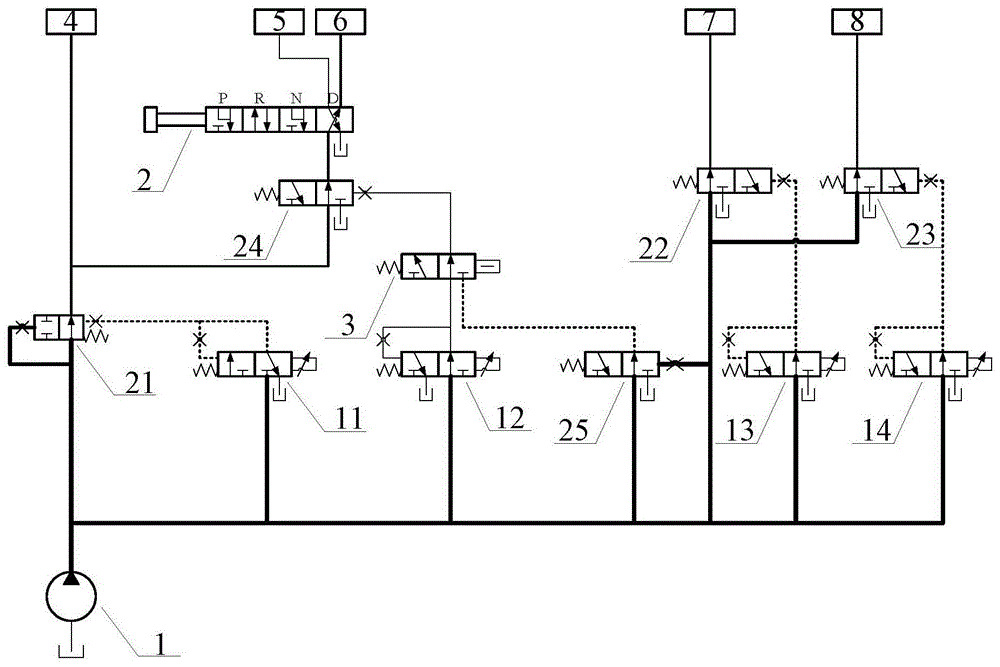

[0029] The limp home oil circuit system of the continuously variable transmission CVT with wet clutch provided by the present invention, such as Figure 3 to Figure 6 As shown, in the conventional wet clutch CVT hydraulic oil circuit (such as figure 1 , figure 2 As shown), there is no need to change the gearbox body structure on the basis, as long as the on-off valve 3 and the fifth mechanical valve 25 are added. The on-off valve 3, the fifth mechanical valve 25, the second solenoid valve 12 and the fourth mechanical valve 24 are used for oil circuit switching between the normal working mode and the limp home mode; when the transmission electronic control unit is working normally, the on-off valve 3 is in the open state, the control oil route of the fourth mechanical valve 24 is controlled by the second solenoid valve 12; Five mec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com