Dynamic coupling system

A technology of power coupling system and power unit, which is applied to the arrangement of multiple different prime movers of power plant, pneumatic power plant, and general power plant, etc., can solve the problems such as the failure of the motor to work and the loss of the reverse driving function of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

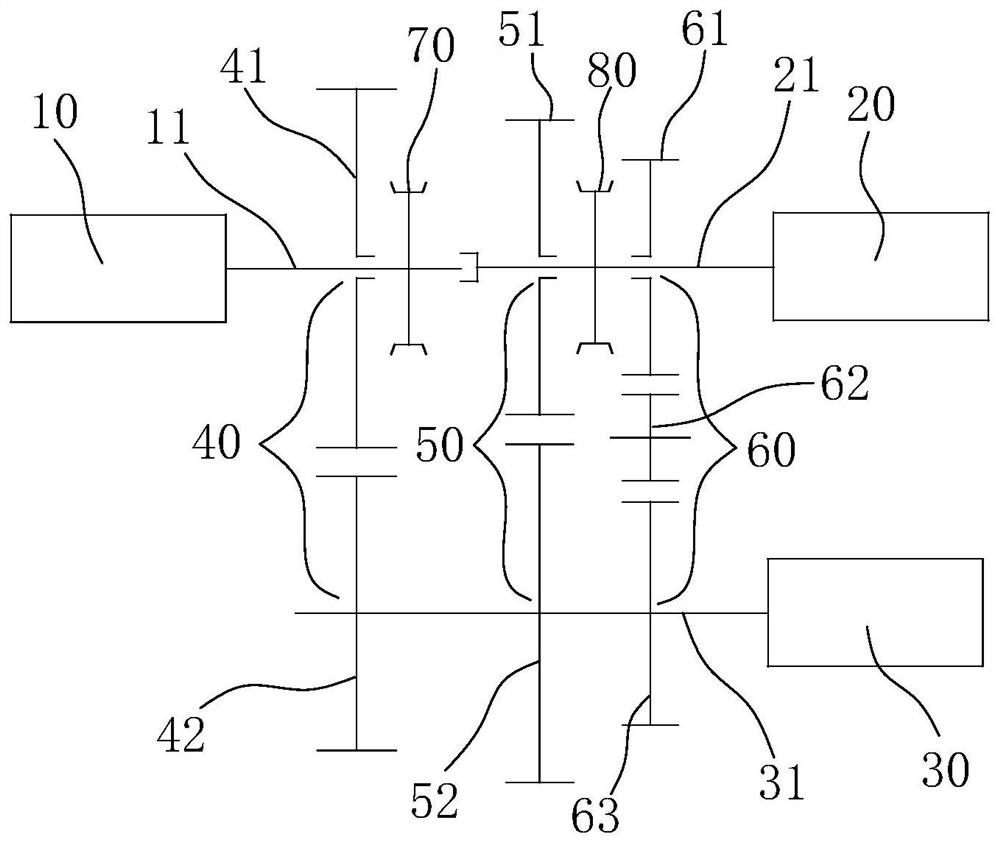

[0009] The technical scheme of the present invention is further described in conjunction with accompanying drawing:

[0010] A power coupling system, comprising an engine power unit 10 and a motor power unit 20, the engine power unit 10 and the motor power unit 20 respectively drive a power output unit 30 through an independent normal driving gear transmission pair, the power of the engine power unit 10 Between the output shaft 11 and the power output unit 30, a reverse gear transmission pair 60 including a transition gear 62 is arranged to transmit power, and the meshing state of the above gear transmission pair is switched by the power switching mechanism during normal driving and reverse driving of the vehicle. When the motor power unit 20 breaks down and cannot work normally, power is transmitted between the power output shaft 11 of the engine power unit 10 and the power output unit 30 through the reverse gear transmission pair 60 of the transition gear 62 to realize the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com