Pipeline explosion-proof device capable of automatically replacing anti-explosion sheets

An explosion-proof device and automatic replacement technology, applied in the valve operation/release device, valve device, engine components, etc., can solve the problems of time-consuming and laborious, affecting the combustion state of the industrial furnace burner, affecting the stable operation of the system, etc., to achieve fast replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

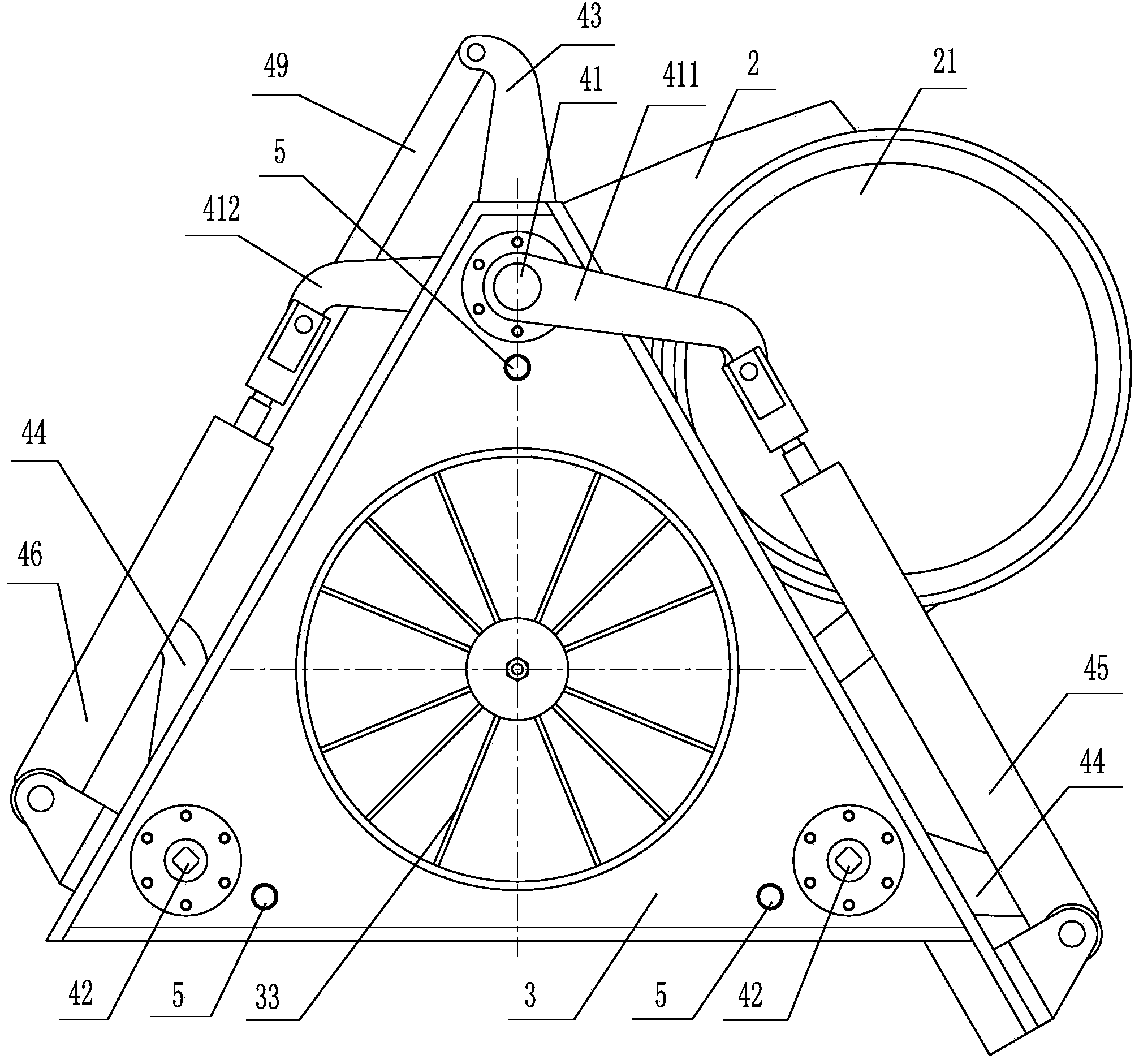

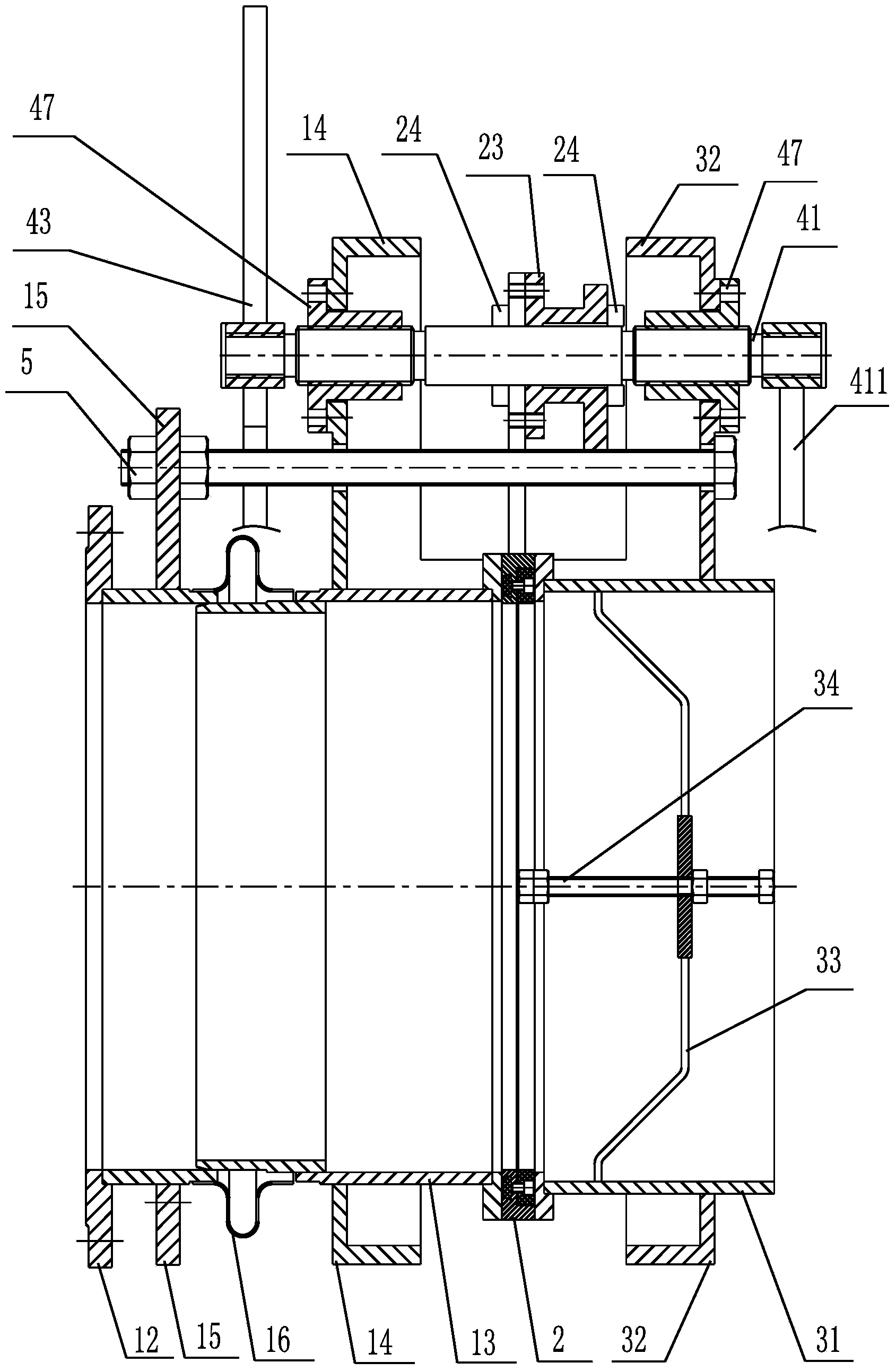

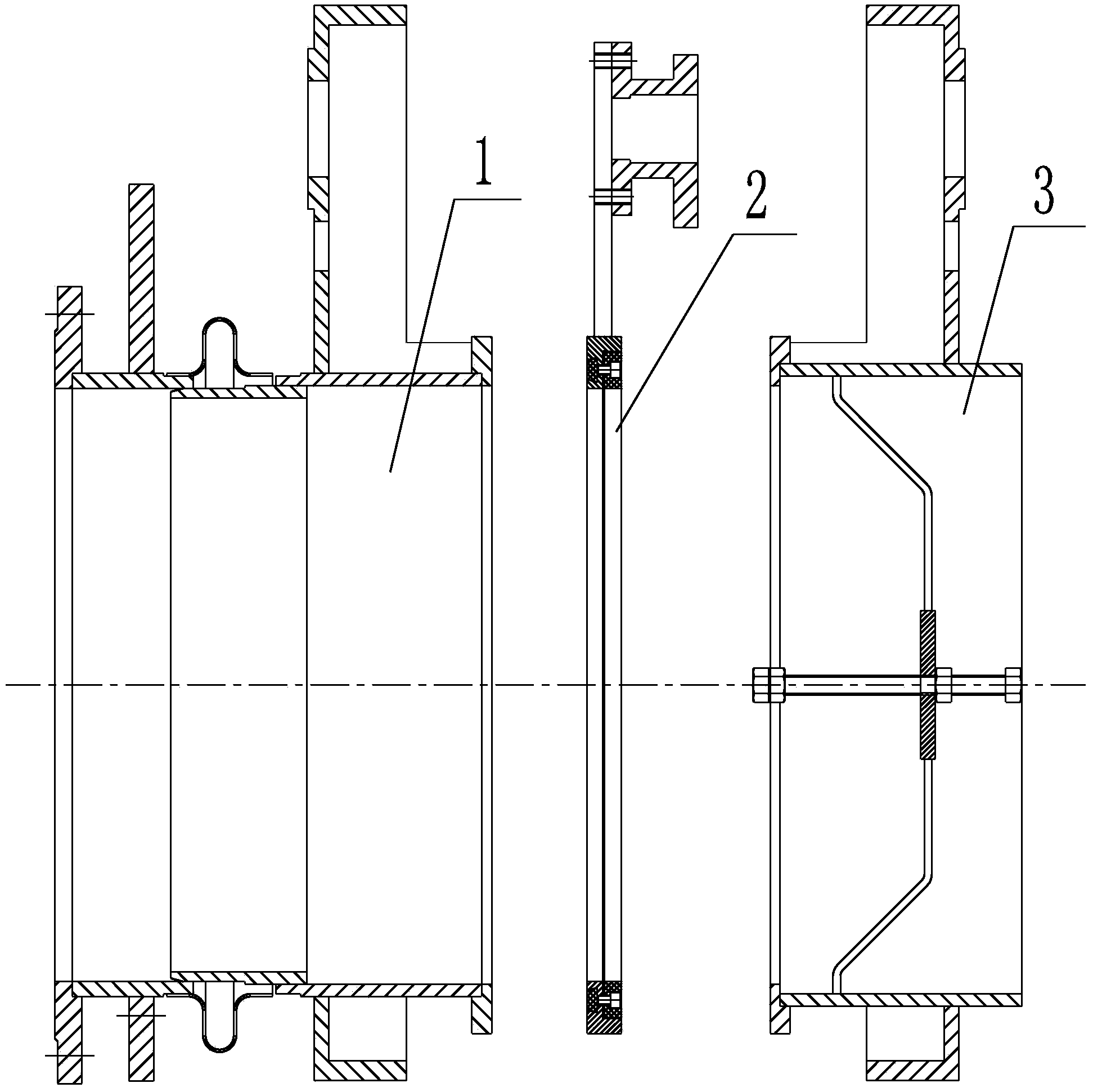

[0032] In order to understand the present invention better, below in conjunction with embodiment and accompanying drawing, the technical solution of the present invention will be further described (see Figure 1-Figure 7 ).

[0033] Such as Figure 1 to Figure 7 As shown, a pipeline explosion-proof device that can automatically replace the explosion-proof disc, which includes a flange connection device 1, a double-hole gate 2, a fixing device 3 and a linkage device 4; the flange connection device 1, the double-hole gate 2 and the fixing The device 3 is connected through the linkage device 4, and the double-hole gate 2 is tightly clamped between the flange connection device 1 and the fixing device 3;

[0034] The flange connection device 1 includes a connecting flange 12 and a connecting pipe 13, the connecting flange 12 and the connecting pipe 13 are fixedly connected as one, and the connecting flange 12 is fixedly connected with the end of the pipeline; the connecting pipe 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com