A profile and non-profile connection structure

A connection structure, non-profile technology, applied in the direction of slender components, building components, etc., can solve the problems of high appearance requirements, high connection method requirements, low positioning accuracy, etc., to achieve excellent appearance, firm and reliable connection methods, and easy installation high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

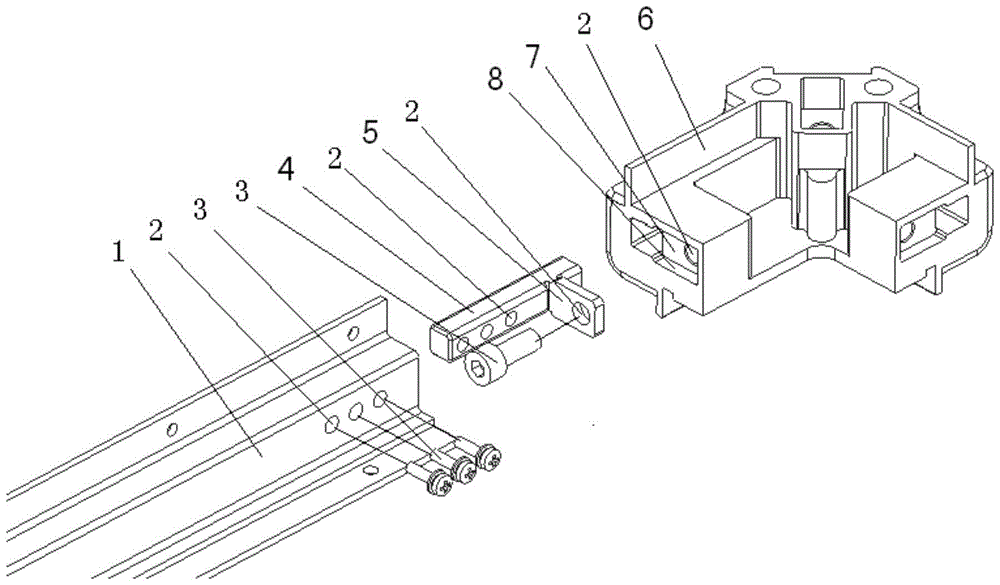

[0019] Such as figure 1 As shown, the profile 1 is a hollow cavity, and the side wall of the profile end is processed with three through holes 2; the pin shaft 4 is processed with three corresponding through holes 2, and the connecting arm 5 has a through hole 2; figure 1 The non-profile 6 used in is a corner block with a positioning groove 8 on it. The mounting surface of the positioning groove 8 has a fixing groove 7 corresponding to the connecting arm 5 and a through hole 2. The through hole 2 is arranged in the fixing groove 7 Inside. During installation, one end of the front part of the pin shaft 4 is inserted into the inner cavity of the terminal part of the profile 1, the through hole 2 on the front part of the pin shaft 4 corresponds to the through hole 2 on the inner cavity of the terminal part of the profile 1, and the screw 3 passes through the end of the profile 1 The through hole 2 on the inner cavity of the connection part is connected with the through hole 2 on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com