A wire receiving jig

A technology of wires and jigs, which is applied in the manufacture of cables/conductors, devices with bendable leads, electrical components, etc. It can solve problems that affect the collection speed, machine damage, and the collection rack cannot continue to rotate and collect, so as to achieve fast collection. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

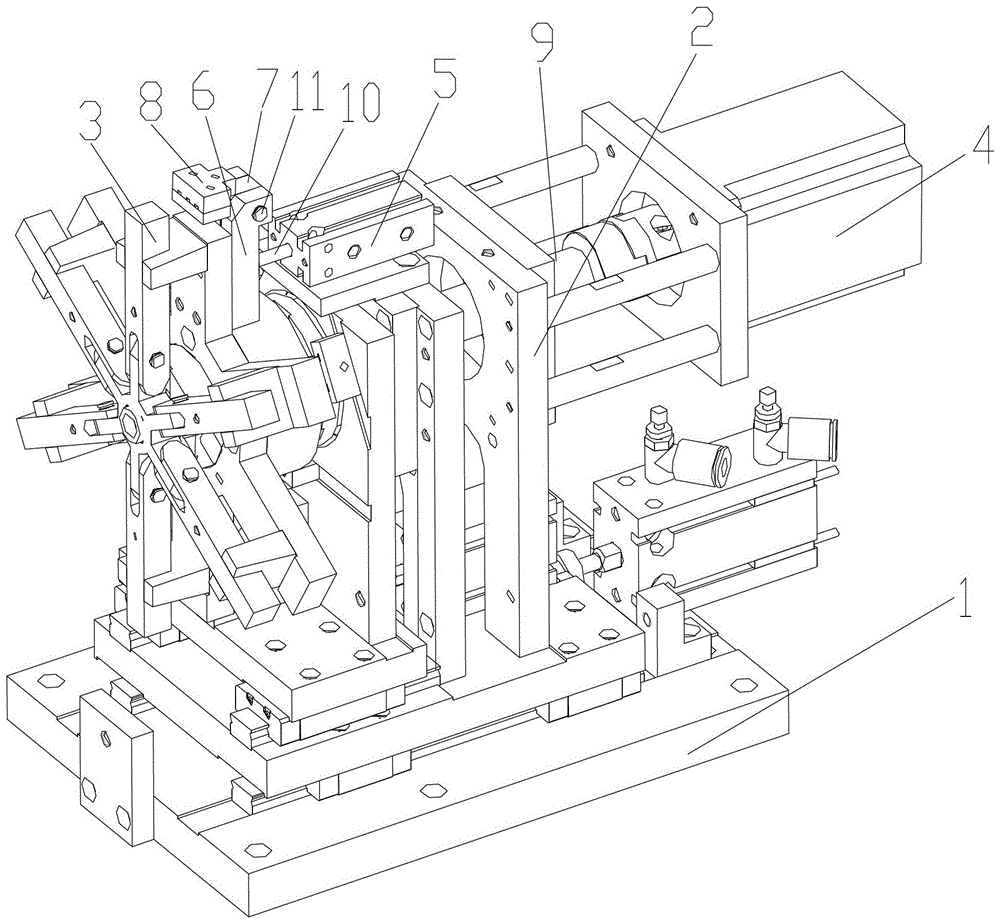

[0011] Such as figure 1 As shown, a wire receiving fixture includes a base 1, a connecting plate 2, a receiving rack 3, a motor 4, a cylinder 5, a fixed seat 6, a rotating arm 7 and a pressing block 8, and a connecting plate is arranged above the base 1 2. A receiving frame 3 is arranged in front of the connecting plate 2, the output shaft 9 of the motor 1 passes through the connecting plate 2 and is connected to the center of the receiving frame 3, and a cylinder 5 is arranged on the top of the connecting plate 2, and the receiving frame 3 is provided with a fixed seat 6, the top of the rotating arm 7 is flexibly connected in the fixed seat 6 through a pin shaft 11, and a pressure block 8 is connected to the front end of the top of the rotating arm 7, and the rear end of the rotating arm 7 is connected to the cylinder of the cylinder 5 Rod 10 is connected. During de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com