Sprouts cultivation device

A cultivation device and sprout vegetable technology, which is applied in the field of sprout vegetable cultivation equipment, can solve the problems of low utilization rate per unit area, complex construction structure, limited planting amount, etc., so as to improve the utilization rate per unit area and reduce the probability of rot , the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

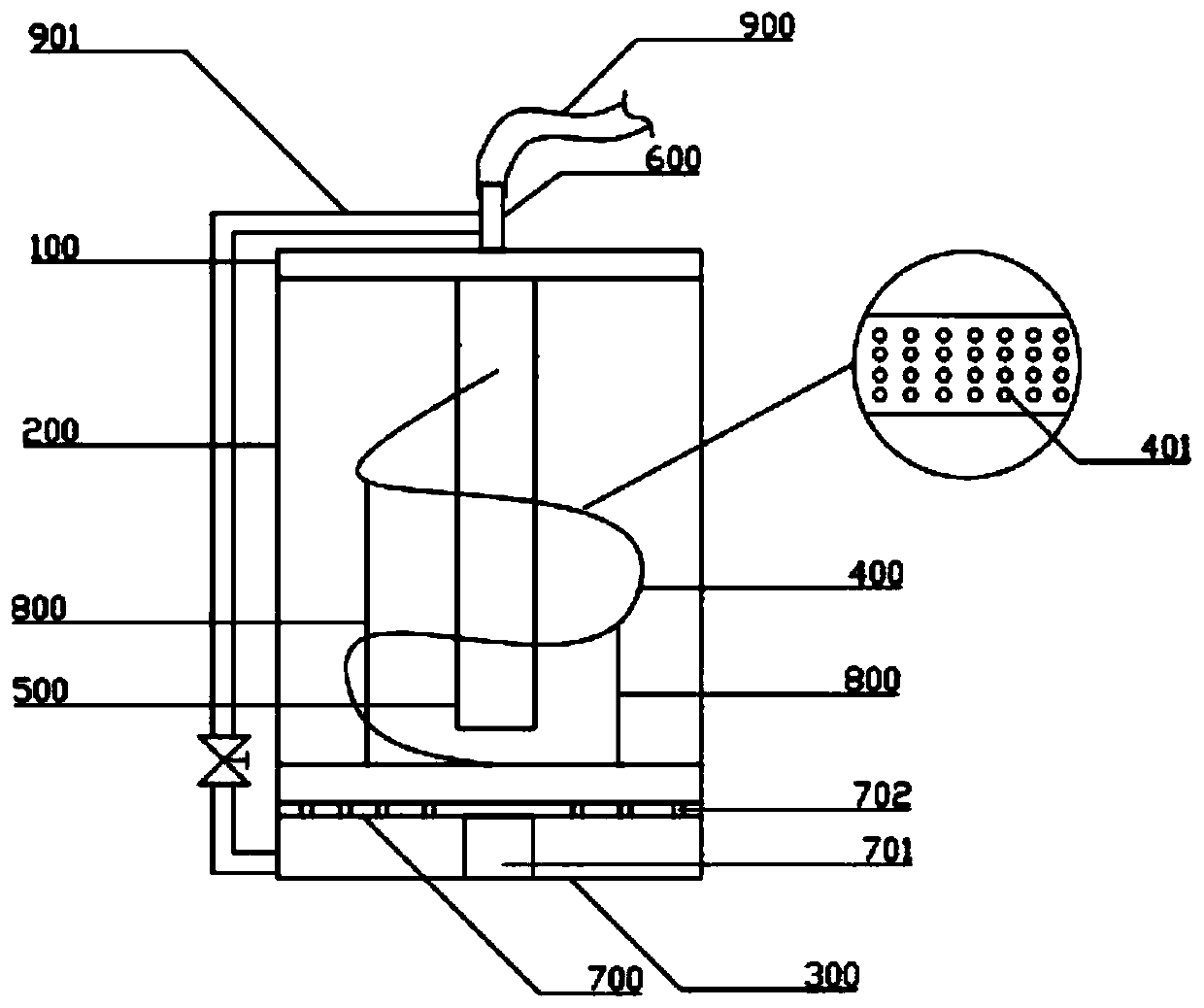

[0037] Depend on Figure 1 ~ Figure 3 , the present invention provides a sprout vegetable cultivation device, comprising a transparent barrel body 200, an upper cover 100 and a base 300 respectively movably connected to the upper and lower edges of the transparent barrel body, and the base 300 is welded with a A spiral support frame 400 of cultivation substrate is laid on it, and the cultivation substrate is sponge or non-woven fabric.

[0038] The lower surface of the upper cover 100 is provided with a supply part 500 for irradiating sprouts and replenishing water. After the upper cover 100 is covered on the transparent barrel body 200, the supply part 500 is inserted into the spiral support frame 400 hollow positions.

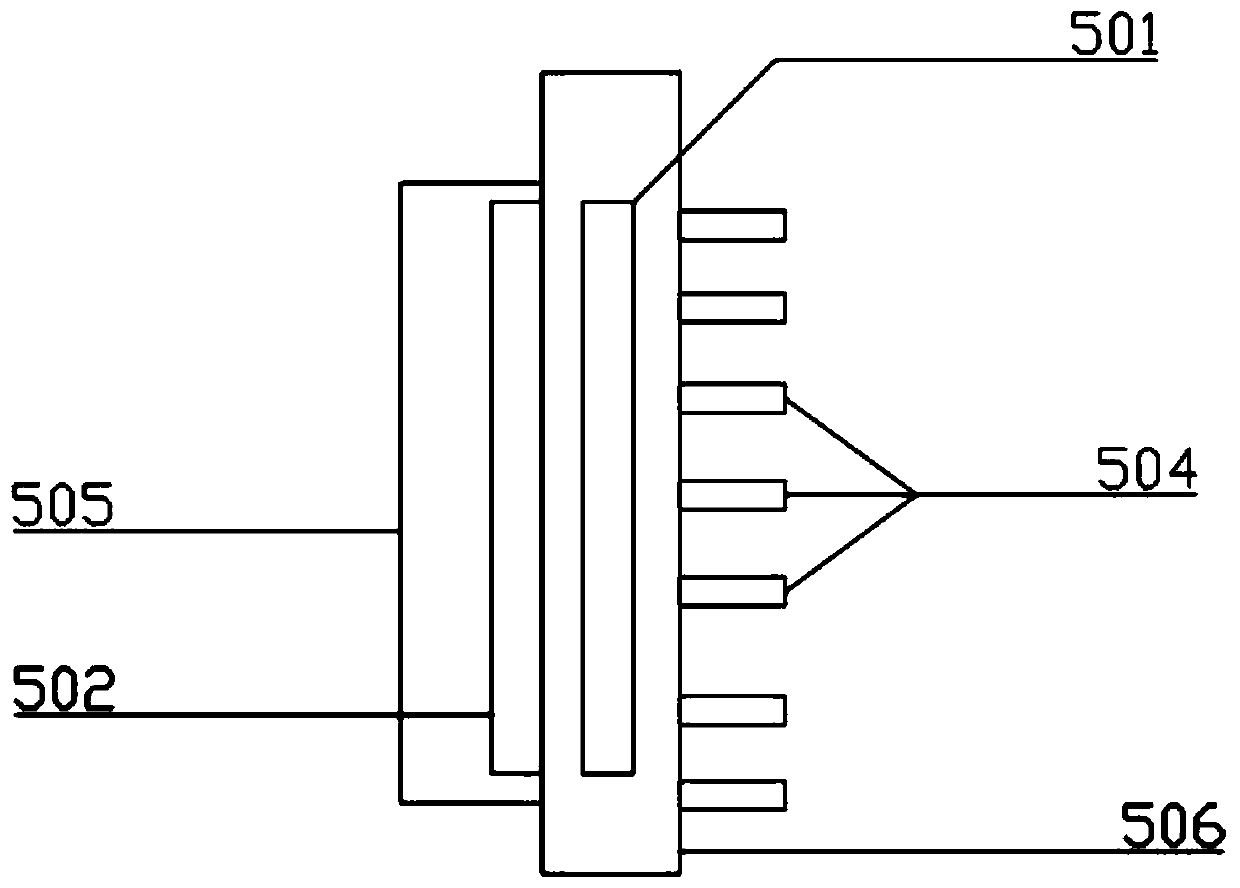

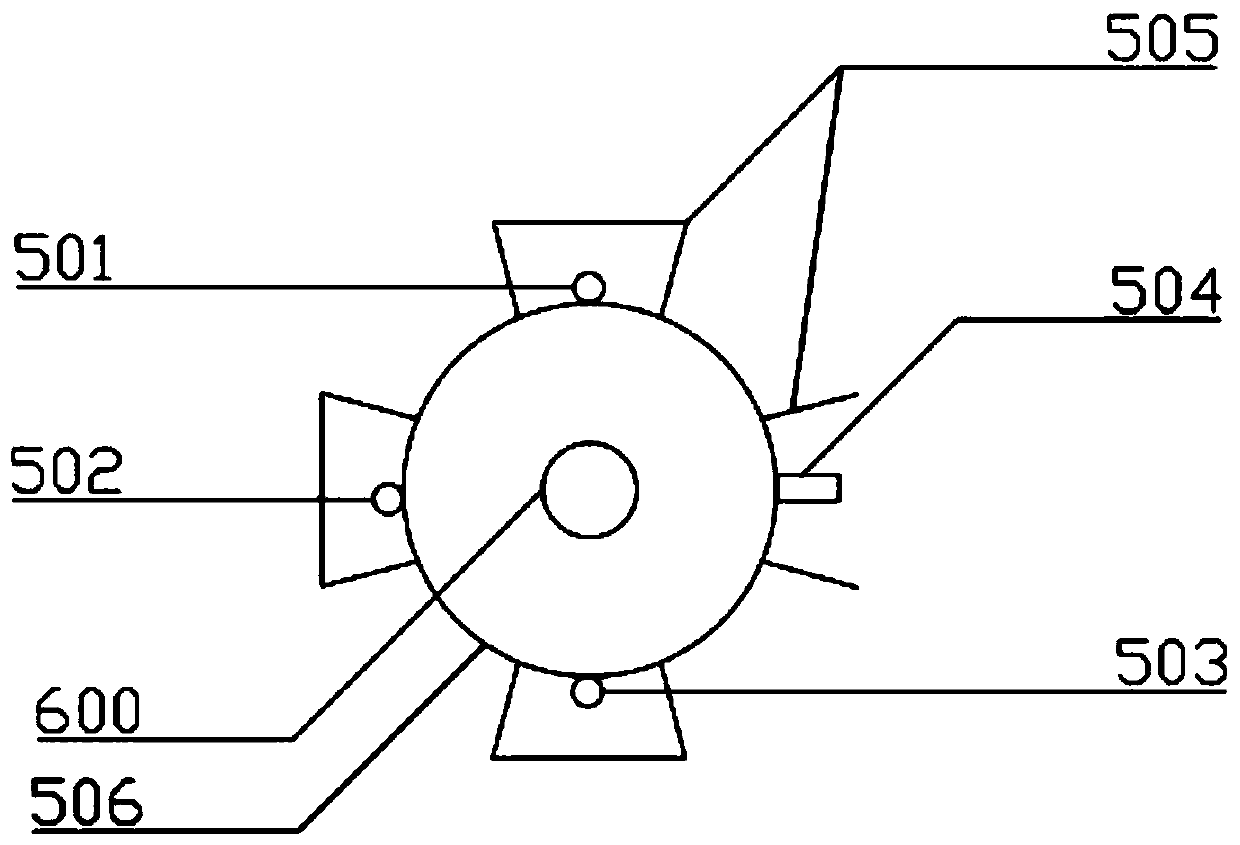

[0039] The supply part 500 includes a water supply structure and an illumination structure. The water supply structure includes a hollow water supply chamber 506 located on the lower surface of the upper cover, (the hollow water supply chamber 506 is a cylin...

Embodiment 2

[0048] Such as figure 1 , figure 2 and Figure 4 As shown, the present invention provides a sprout vegetable cultivation device, comprising a transparent barrel body 200, an upper cover 100 and a base 300 respectively movably connected to the upper and lower edges of the transparent barrel body, and the base 300 is welded with an upwardly extending And a spiral support frame 400 of a cultivation substrate is spread thereon, and the cultivation substrate is sponge or non-woven fabric.

[0049] The lower surface of the upper cover 100 is provided with a supply part 500 for irradiating sprouts and replenishing water. After the upper cover 100 is covered on the transparent barrel body 200, the supply part 500 is inserted into the spiral support frame 400 hollow positions.

[0050] The supply part 500 includes a water replenishment structure and an illumination structure. The water replenishment structure includes a hollow water replenishment cavity 506 located on the lower sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com