Vehicle pneumatic tires

一种车辆、轮胎的技术,应用在充气轮胎的增强层、重型轮胎、重型车辆等方向,能够解决有限带束耐用性等问题,达到减小滚动阻力、提高滚动阻力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

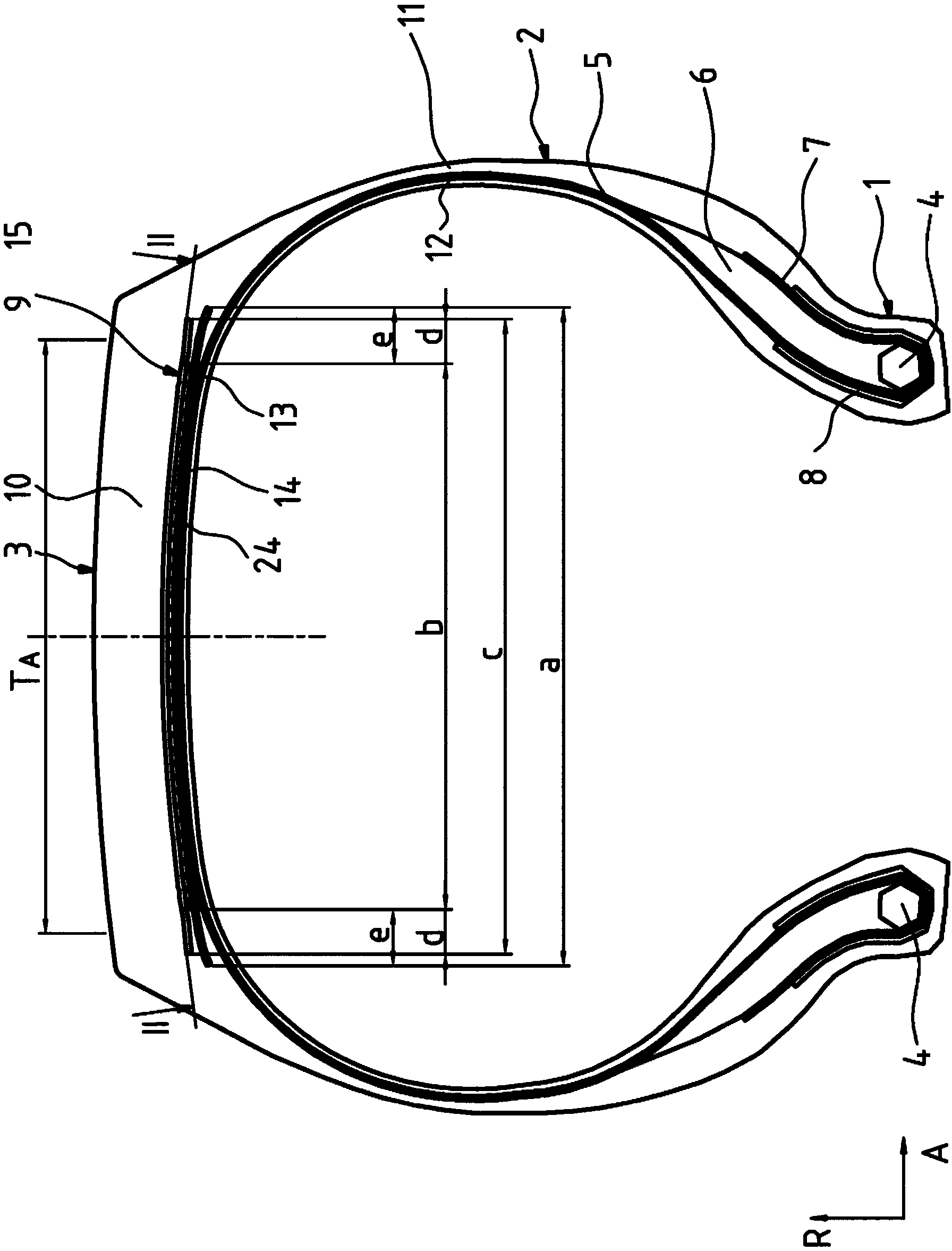

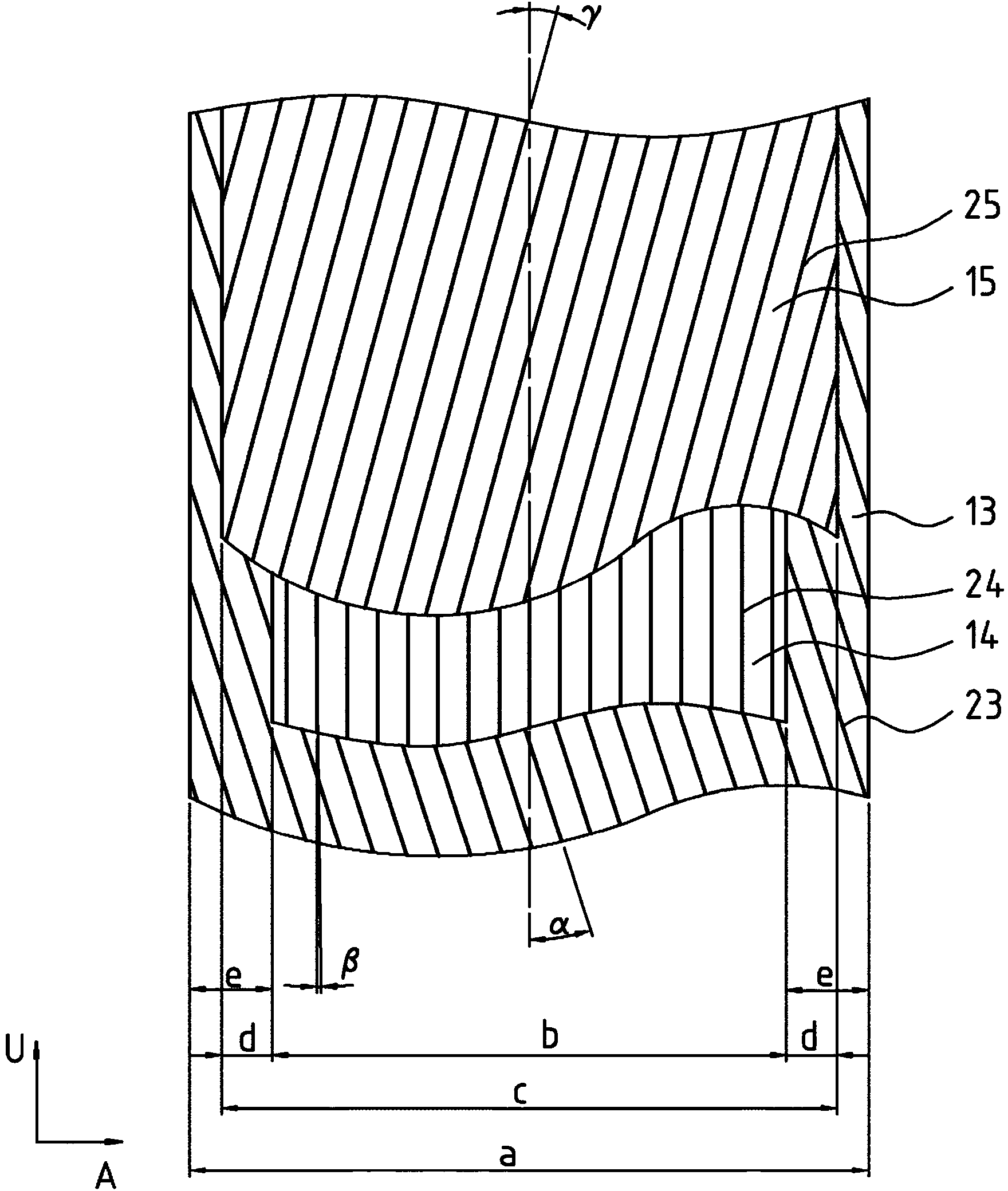

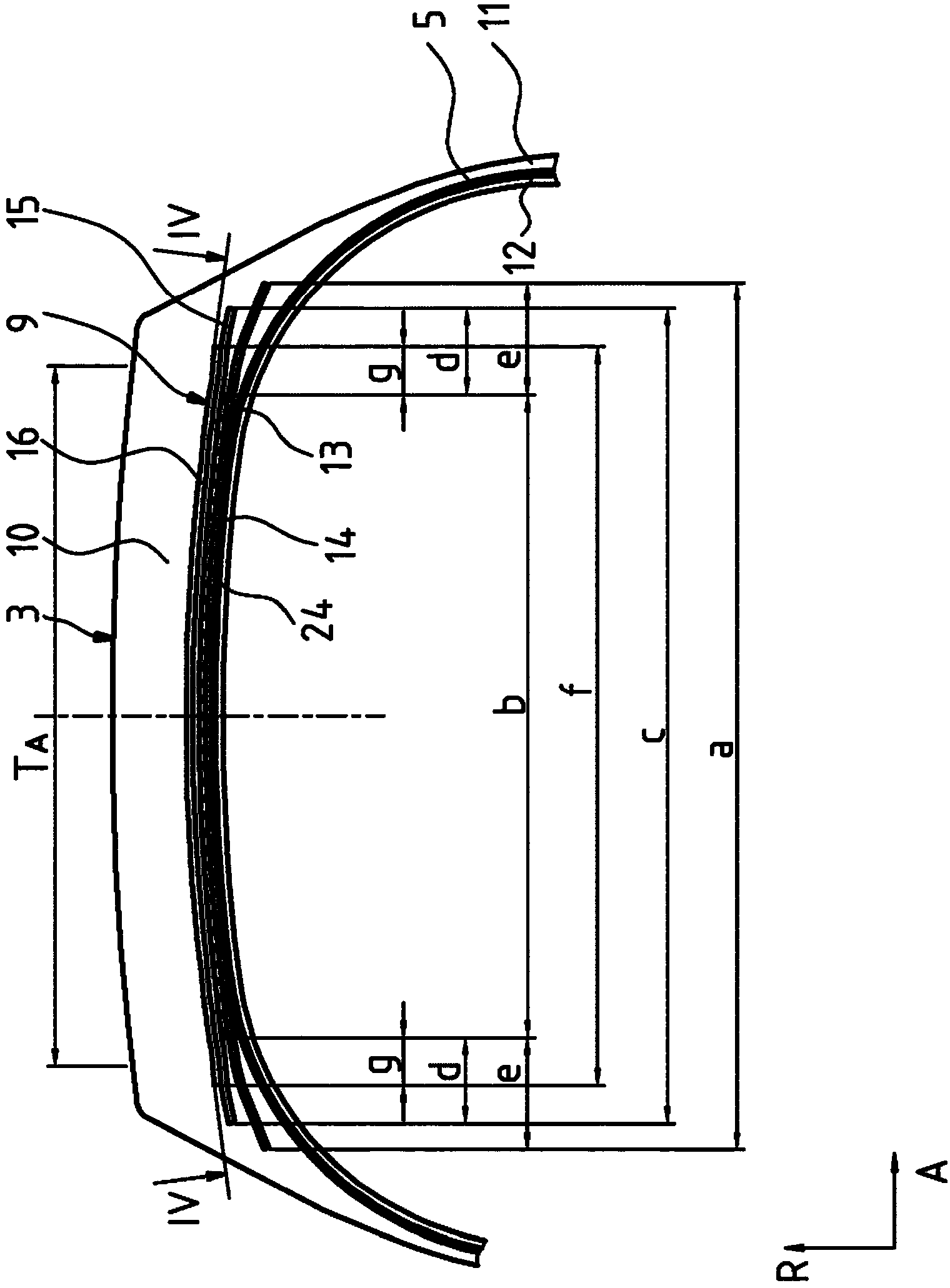

[0054] figure 1 and figure 2 A pneumatic tire of radial design for a utility vehicle is shown, having two side walls 2 extending in the direction R of the vehicle tire, and an axially formed between them A crown area3. These side walls are each formed on their radially inwardly directed extension ends with a bead region 1 in which a bead core 4 of known design is formed, the bead core It has a high tensile strength in the circumferential direction U and extends over the circumference of the tire in this circumferential direction. The bead cores 4 are formed by winding in a known manner steel wires extending in the circumferential direction U of the pneumatic vehicle tire and embedded in rubber. A tip 6 having a triangular cross section is formed on the bead core 4 by a hard rubber material. The pneumatic vehicle tire is formed with a carcass 5 extending outward in the radial direction R of the pneumatic vehicle tire from a bead core 4 formed in the left bead region 1 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com