Seedling separation and seedling taking assembly of artemisia selengensis cutting machine

A seedling separating device and cutting machine technology, applied in planting methods, transplanting machinery, horticulture, etc., can solve the problems of high labor intensity, high labor consumption, low operating efficiency, etc., and achieve the effect of improving reliability and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

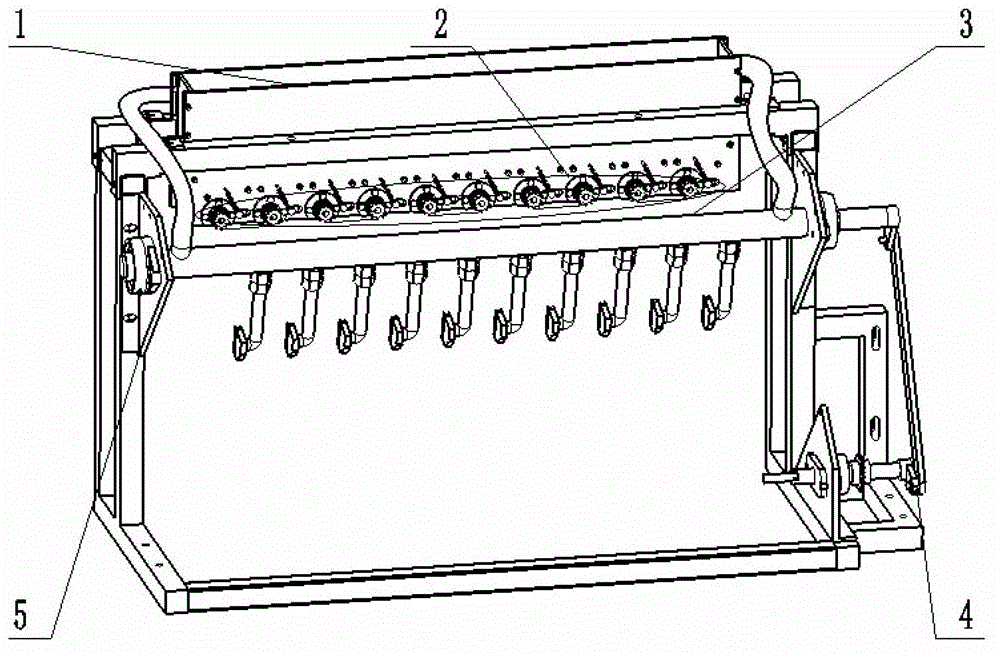

[0031] refer to Figure 1 to Figure 11 , the device for separating seedlings and taking seedlings of a kind of Artemisia quinoa cuttage machine of the present invention, comprises seedling case 1, separating device 2, taking seedlings device 3, crank rocker mechanism 4 and frame 5.

[0032] in:

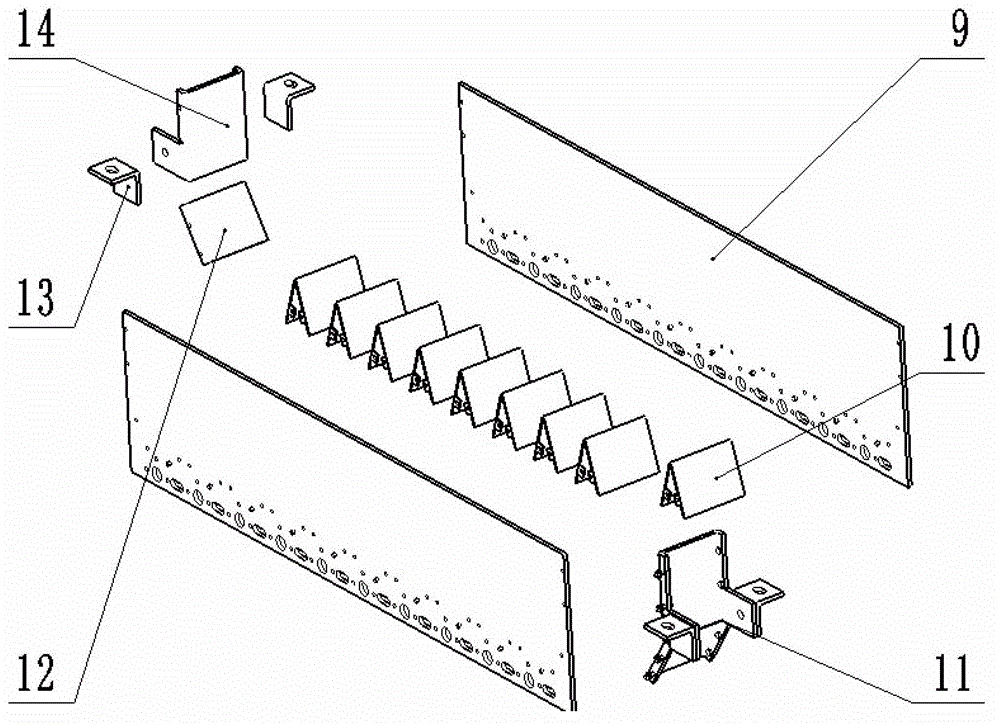

[0033] Described seedling box 1 comprises front and back two main boards 9, dividing plate 10 and left and right two side supports 11; Side plate suspension 13 is arranged; Two main boards 9 are connected by bolts with two side supports 11, and dividing plate 10 is installed between two seedling box main boards 9 by bolts.

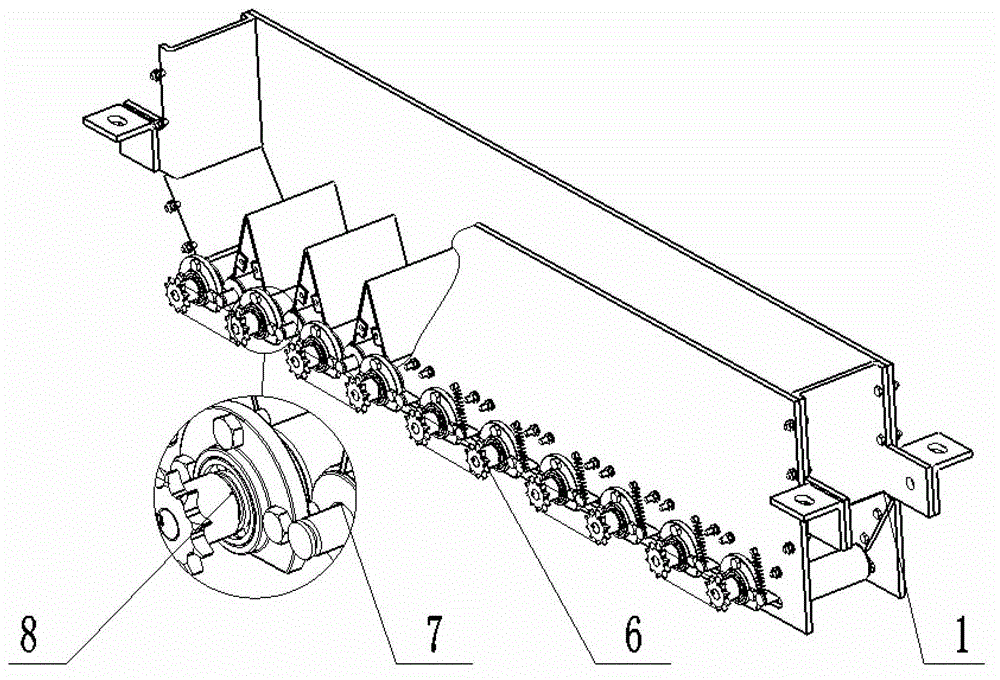

[0034]Described seedling separating device 2 comprises 1 dynamic fixed drum device 6, 9 moving drum devices 7, 10 fixed drum devices 8, and described fixed drum device 8 includes fixed drum 15, bearing seat 16, fixed drum shaft 17 And sprocket wheel 18, described fixed drum 15 is fixedly installed on the fixed drum shaft 17, and the two ends of described fixed d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com