Horizontal sliding rear flush unit system and its manufacturing process

A manufacturing process and unit body technology, which is applied to building components, building insulation materials, walls, etc., can solve problems such as drop, inconsistent materials, and occupying indoor area, so as to reduce randomness, reduce processes, and improve indoor perception Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

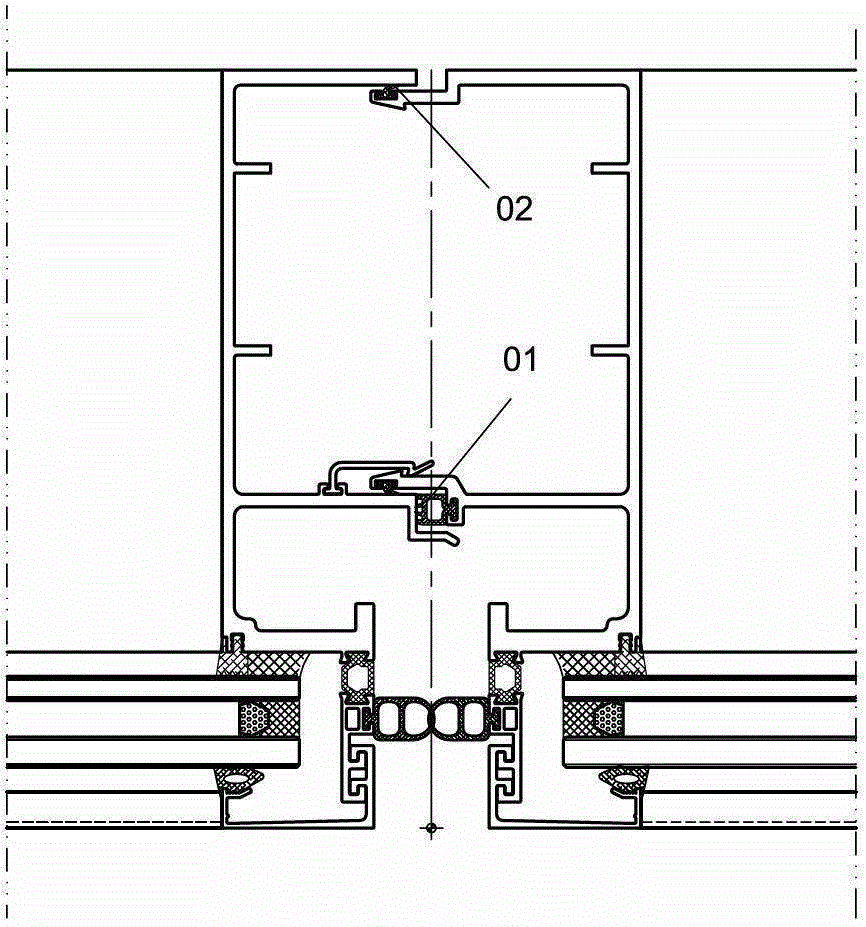

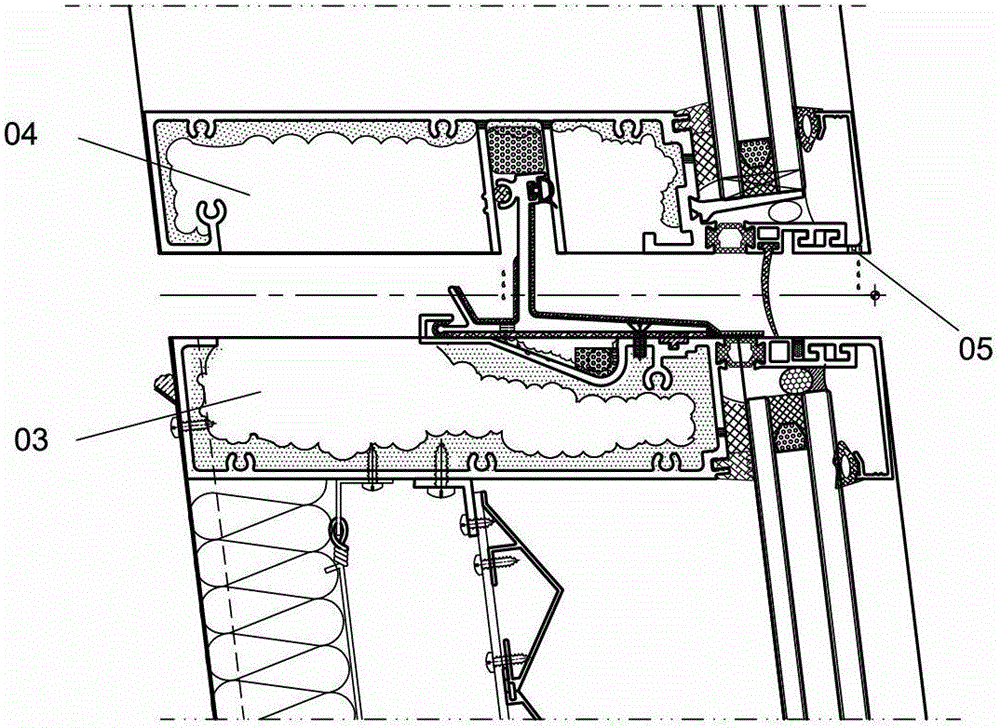

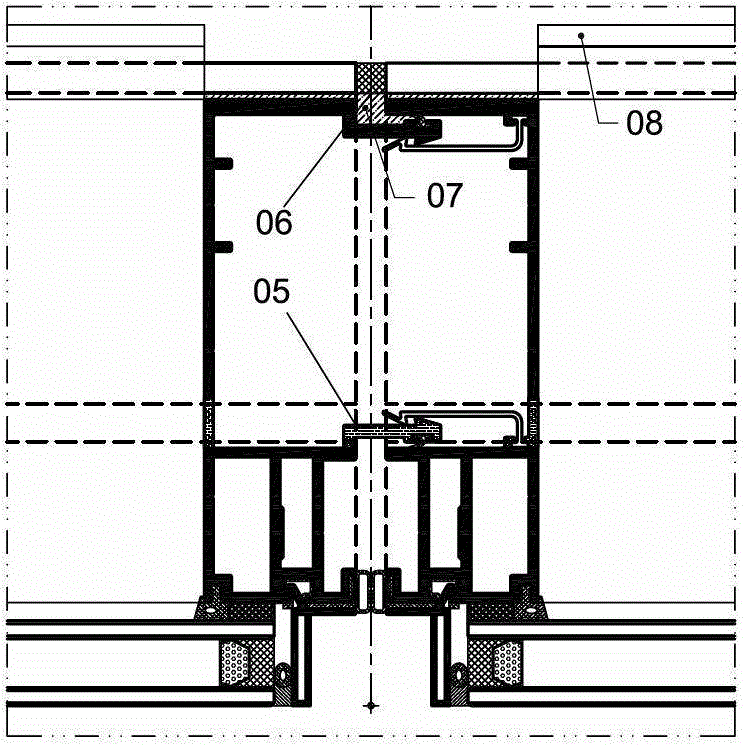

[0039] The horizontal sliding rear flush unit body system provided by the present invention, such as Figure 6 , 8 , 9 and 10, including curtain wall panel 1, profile public column 2 and female column 3 connected to the left and right edges of the curtain wall panel, and profile upper rail 4 and profile lower rail connected to the upper and lower edges of curtain wall panel 1 5. The public column 2 and the female column 3 on the adjacent curtain wall panel 1 are fitted together and form two front and rear sealing structures at the joint joint: the first vertical sealing structure a (with sealing strip B) and The second vertical sealing structure b (with sealing strip B1) (see Figure 9 ), between the upper cross member 4 and the lower cross member 5 on the adjacent curtain wall panel 1 through the front first insertion leg 41 and the rear second insertion leg 42 arranged on the upper end surface of the upper cross member 4 and The plug-in structure on the lower rail 5 fits t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com