Mortar preparation raw material and method for producing insulation board from same

A thermal insulation board and raw material technology, applied in the direction of chemical instruments and methods, manufacturing tools, lamination auxiliary operations, etc., can solve problems that are difficult for ordinary consumers to accept, affect the aesthetics of exterior walls, and safety hazards of silicon-calcium boards, etc., to achieve Strong anti-deformation ability, excellent heat insulation performance, good sound absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A raw material for mortar preparation, which is made of the following raw materials in parts by weight: 450 parts of sand screened through a 600-800 mesh screen, 180 parts of cement, 220 parts of mineral powder, 35 parts of resin powder, 25 parts of calcium powder, and fibers with a length of 2-6 cm 25, accelerator 8, early strength agent 8, water 360, rubber powder 22, cellulose 5.

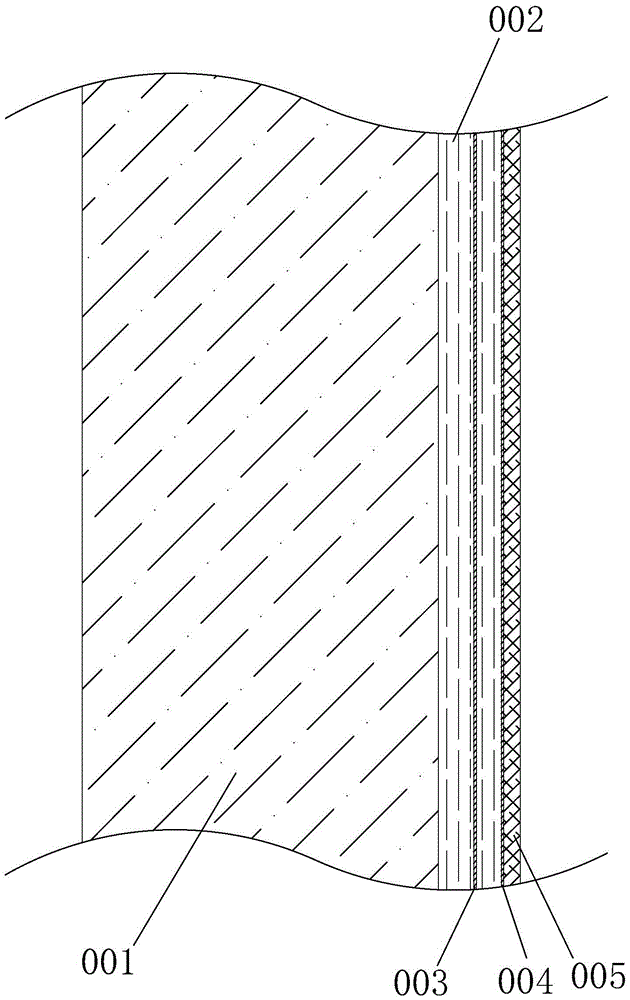

[0034] Such as figure 1 figure 2 Shown, utilize above-mentioned mortar preparation raw material to make the method for insulation board, comprise the following steps:

[0035] Step 1. Dry material mixing

[0036] Take sand, cement, mineral powder, resin powder, calcium powder, fiber, quick-setting agent, and early-strength agent in parts by weight and fully mix them with a mixing device to form a dry material;

[0037] Step 2. Prepare glue

[0038] Take rubber powder and cellulose by weight, add half of the total weight of water, fully stir to make glue;

[0039] Step 3: Prepare mort...

Embodiment 2

[0057] A raw material for mortar preparation, which is made of the following raw materials in parts by weight: 550 sand obtained by screening through a 600-800 mesh screen, 220 cement, 180 mineral powder, 45 resin powder, 15 calcium powder, and fibers with a length of 2-6 cm 15. Accelerator 12, Early Strength Agent 12, Water 400, Rubber Powder 25, Cellulose 8.

[0058] Such as figure 1 figure 2 Shown, utilize above-mentioned mortar preparation raw material to make the method for insulation board, comprise the following steps:

[0059] Step 1. Dry material mixing

[0060] Take sand, cement, mineral powder, resin powder, calcium powder, fiber, quick-setting agent, and early-strength agent in parts by weight and fully mix them with a mixing device to form a dry material;

[0061] Step 2. Prepare glue

[0062] Take rubber powder and cellulose by weight, add half of the total weight of water, fully stir to make glue;

[0063] Step 3: Prepare mortar

[0064] Mix the dry materia...

Embodiment 3

[0081] A raw material for mortar preparation, which is made of the following raw materials in parts by weight: 500 parts of sand screened through a 600-800 mesh screen, 200 parts of cement, 200 parts of mineral powder, 40 parts of resin powder, 20 parts of calcium powder, and fibers with a length of 2-6 cm 20, accelerator 10, early strength agent 10, water 380, rubber powder 24, cellulose 7.

[0082] Such as figure 1 figure 2 Shown, utilize above-mentioned mortar preparation raw material to make the method for insulation board, comprise the following steps:

[0083] Step 1. Dry material mixing

[0084] Take sand, cement, mineral powder, resin powder, calcium powder, fiber, quick-setting agent, and early-strength agent in parts by weight and fully mix them with a mixing device to form a dry material;

[0085] Step 2. Prepare glue

[0086] Take rubber powder and cellulose by weight, add half of the total weight of water, fully stir to make glue;

[0087] Step 3: Prepare mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com