Non-formwork-removable lightweight interior partition wall panel and its integral grouting construction method

An internal partition wall, lightweight technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of unpopular use, short fire resistance time, wall cracks, etc., to achieve good overall use effect, strong fire resistance, and prevent arch cracking or cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

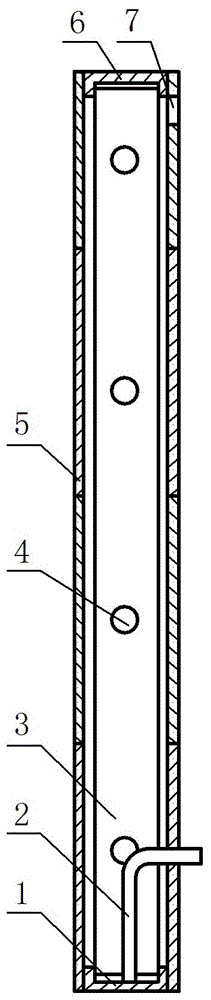

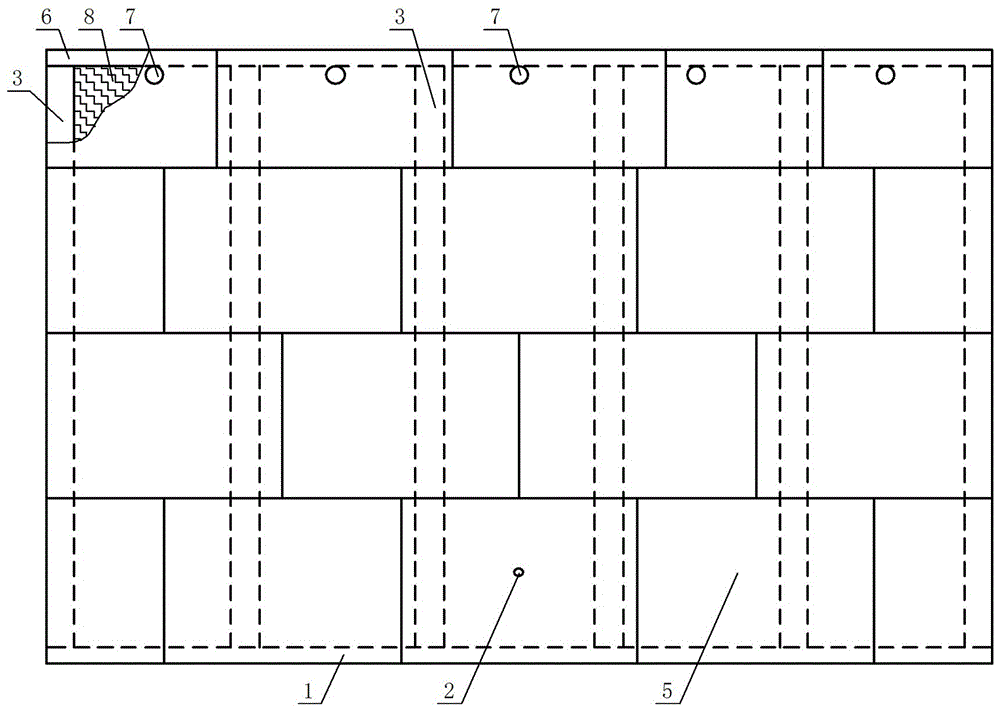

[0033] Example: see figure 1 and figure 2 , in the figure, 1-lower channel iron, 2-water and electricity piping, 3-column, 4-flow hole, 5-engineering fiberboard, 6-upper channel iron, 7-grouting hole, 8-filling slurry.

[0034] The non-removable lightweight inner partition wall panel includes a column 3 and a panel, wherein: the upper end and the lower end of the column 3 are fixedly connected with the upper channel iron 6 and the lower channel iron 1 respectively, and the two sides of the column 3 are respectively provided with engineering fiber boards 5 as The upper end of the engineering fiberboard 5 on one side of the panel is provided with grouting holes 7 at intervals, the gap between the engineering fiberboards 5 on both sides is filled with filling slurry 8, and there are multiple columns 3 arranged at intervals, and the columns 3 are provided with flow pulp hole.

[0035] There is a gap of 1-2mm between the top of the column 3 and the top of the upper channel iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com