Method for detecting loss of fluid or blockage in a hydraulic circuit using exponentially weighted moving average (EWMA) filter

A hydraulic circuit, hydraulic fluid technology, applied in the direction of components with teeth, gear lubrication/cooling, transmission control, etc., can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

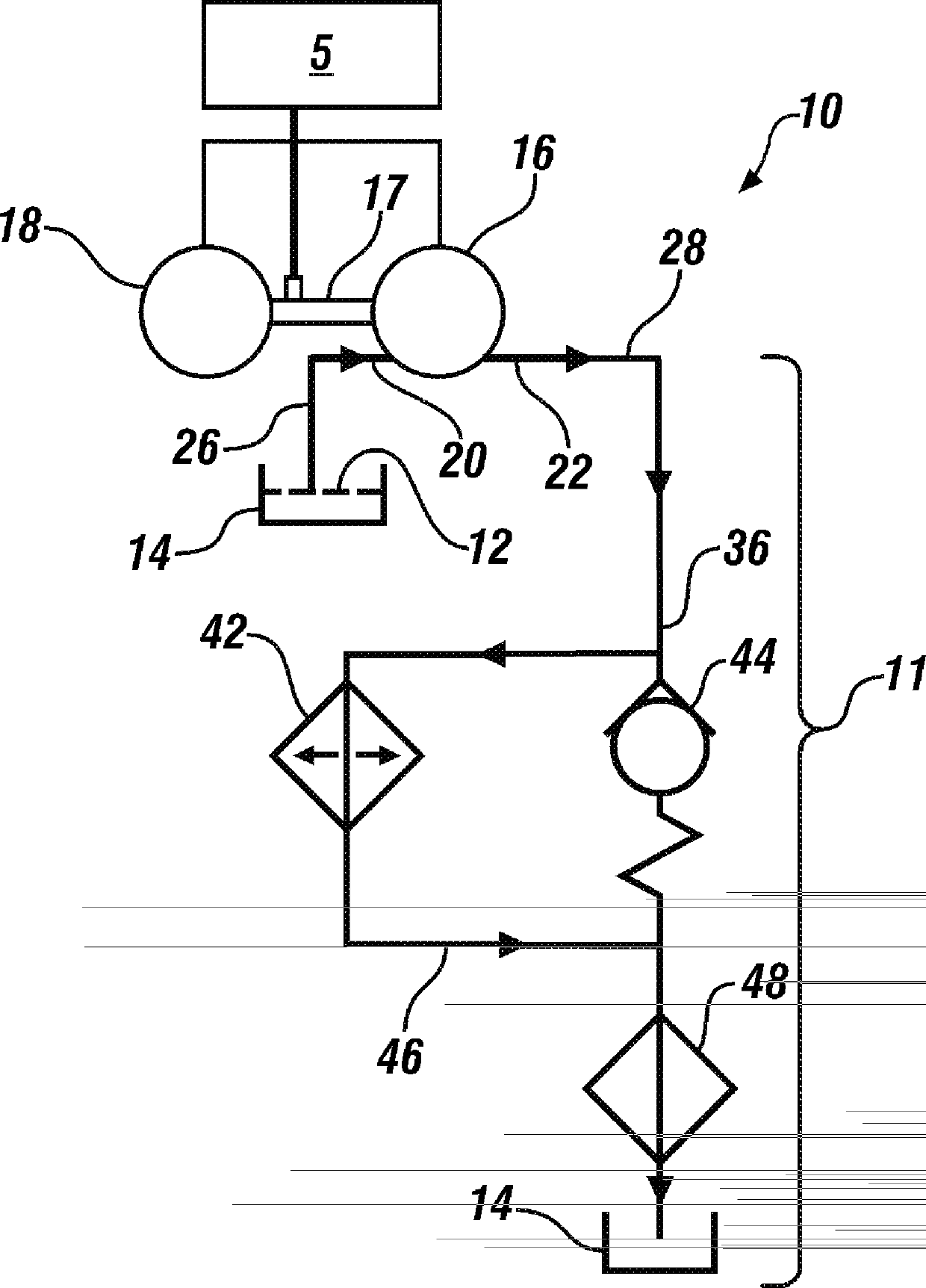

[0068] Referring now to the drawings, in which are shown for the purpose of illustrating certain exemplary embodiments only and not for the purpose of limiting these embodiments, figure 1 An exemplary hydraulic control system 10 for a transmission is schematically shown. In one exemplary embodiment, the transmission is a direct range transmission for a battery electric vehicle. Accordingly, direct gear transmissions do not include a gear selection system that utilizes hydraulically activated and deactivated torque-transmitting devices. The hydraulic control system 10 is used to lubricate the transmission and provide temperature management of the transmission by communicating hydraulic fluid 12 from a sump 14 to at least one of a plurality of subsystems of the hydraulic circuit 11 . The various subsystems of the hydraulic circuit 11 may include a cooler subsystem 42 and a lubrication and temperature management subsystem 48 . However, in some embodiments, hydraulic circuit 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com