Driver air conditioner test bed system

A test bench and air conditioner technology, applied in the direction of railway vehicle testing, etc., can solve the problems of high maintenance cost, inability to accurately judge the air conditioner failure, and long debugging cycle, so as to improve the maintenance quality, improve the product maintenance quality, and avoid disassembly and maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

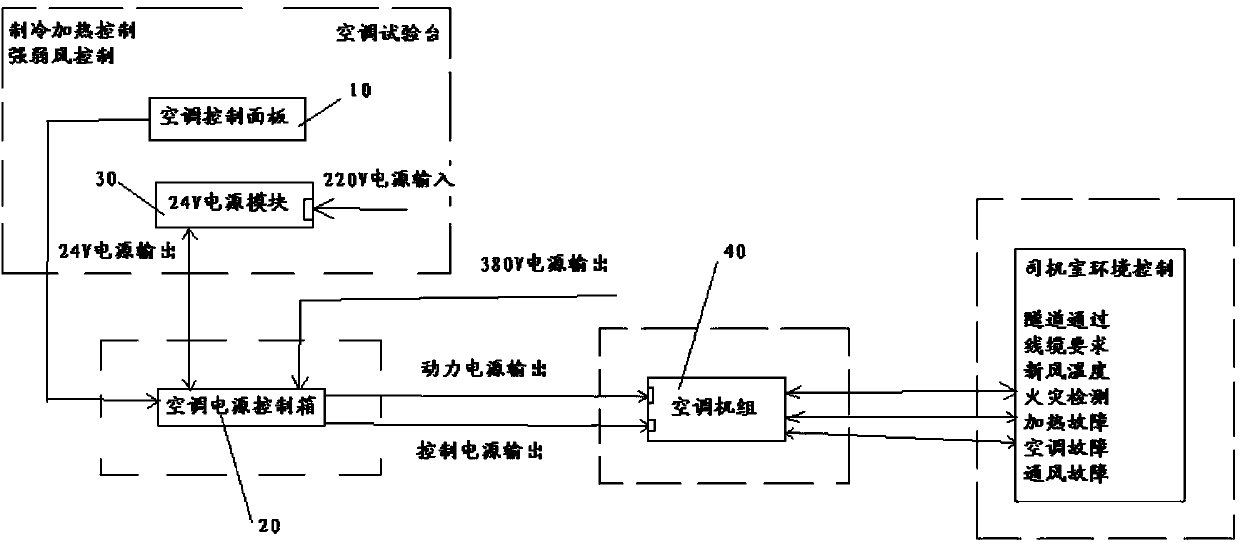

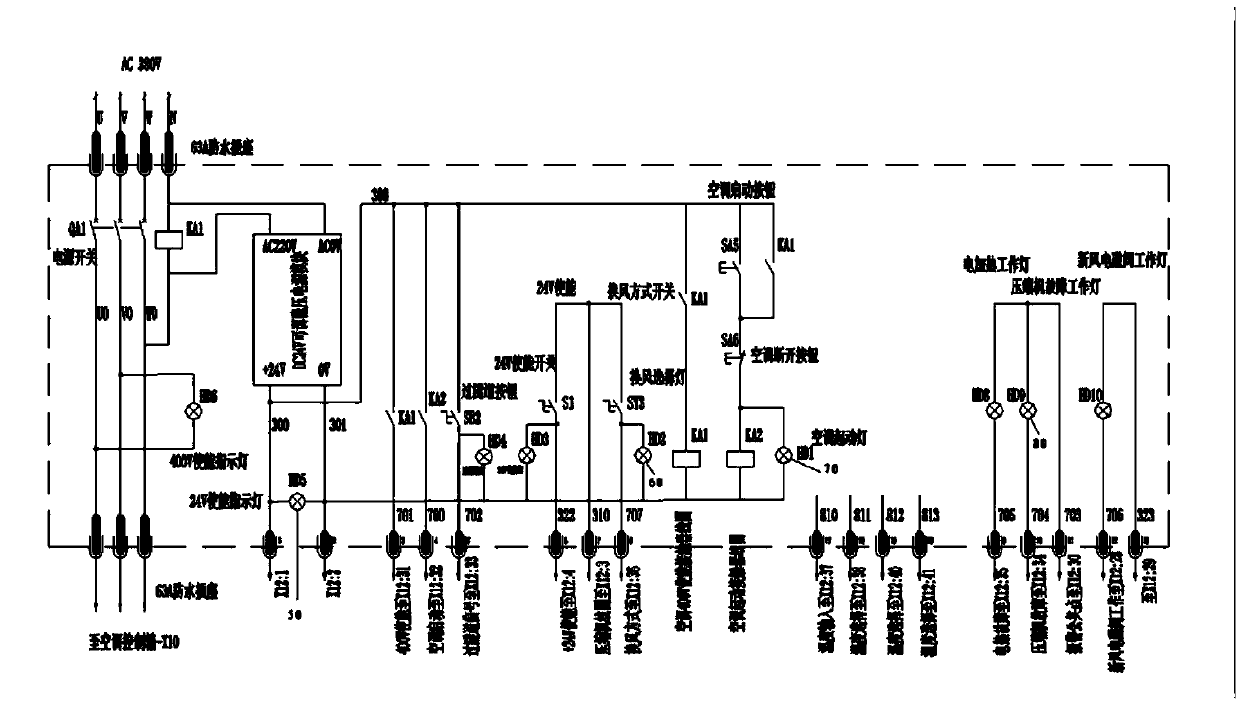

[0027] see figure 1 and figure 2 , the embodiment of the present invention provides a driver's air conditioner 40 test bench system for testing the driver's air conditioner 40 , wherein the driver's air conditioner 40 test bench system includes a controller 10 , an air conditioner power control box 20 and a power module 30 . The controller 10 has a liquid crystal display; the air conditioner power control box 20 is electrically connected to the control panel, and the control panel is used to send control signals to the air conditioner power control box 20; the power module 30 is connected to the air conditioner The power control box 20 is electrically connected; wherein, the air conditioner power control box 20 is used for electrically connecting with the driver's air conditioner 40 to be tested.

[0028] The driver’s air conditioner test bench system provided by the above technical proposal is to provide a practical process platform for the maintenance test of the driver’s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com