Vapor condensation heat-exchange test device

A technology of steam condensation and thermal testing, applied in the field of heat exchangers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

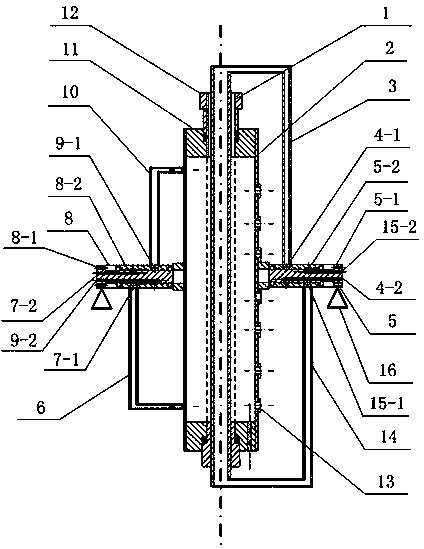

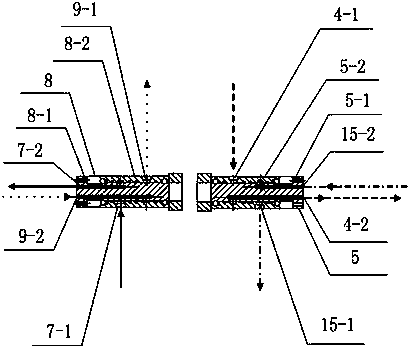

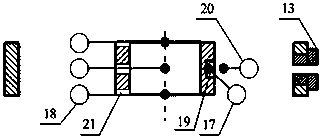

[0016] Referring to the accompanying drawings, the present invention provides a steam condensation heat exchange test device, wherein the test device includes a heat exchange inner tube 1, a condensation section shell 2, a material outlet pipe 3, a first two-way rotary joint 5, a steam outlet pipe 6, The second two-way rotary joint 8, steam inlet pipe 10, sealing gasket 11, internal thread sleeve 12, material inlet pipe 14, fixed base 16, pipe wall thermocouple 17, pipe fluid thermocouple 18, pipe outer steam thermocouple 20. The test device is divided into three parts: the shell of the condensation section, the two-way rotary joint, and the heat exchange inner tube. As shown in the figure, the material flows into the heat exchange inner tube 1 through the material inlet flow path 15-2 through the first two-way rotary joint 5 and the material inlet pipe 14 by an external force (such as a circulating pump), and then passes through the heat exchange circular tube and then passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com