Method for manufacturing light emitting diode

A technology of light-emitting diodes and manufacturing methods, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of poor installation adaptability and single installation method, and achieve the effect of strong installation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

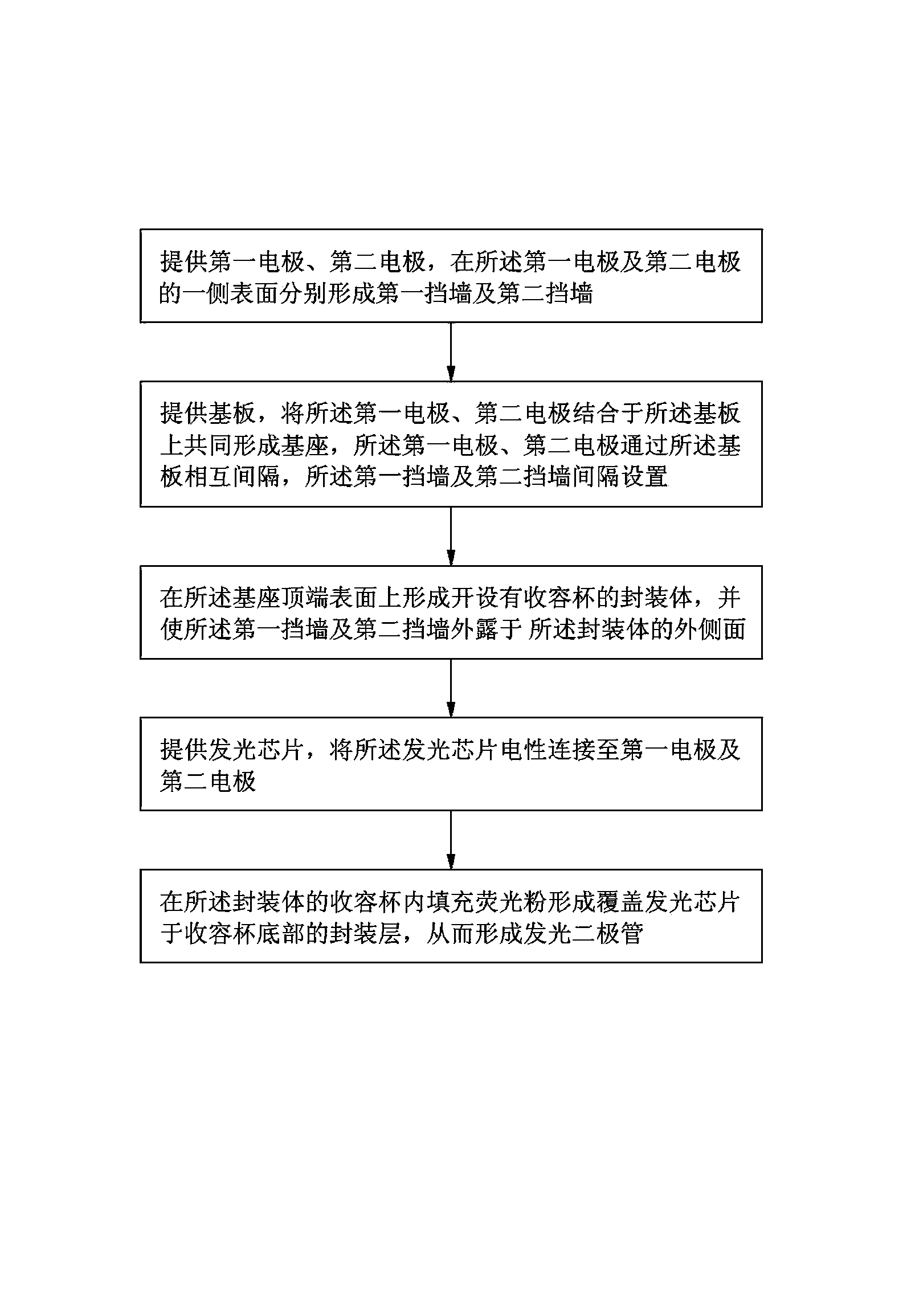

[0020] figure 1 A schematic diagram of the production process of the light-emitting diode provided by the present invention is shown, which includes:

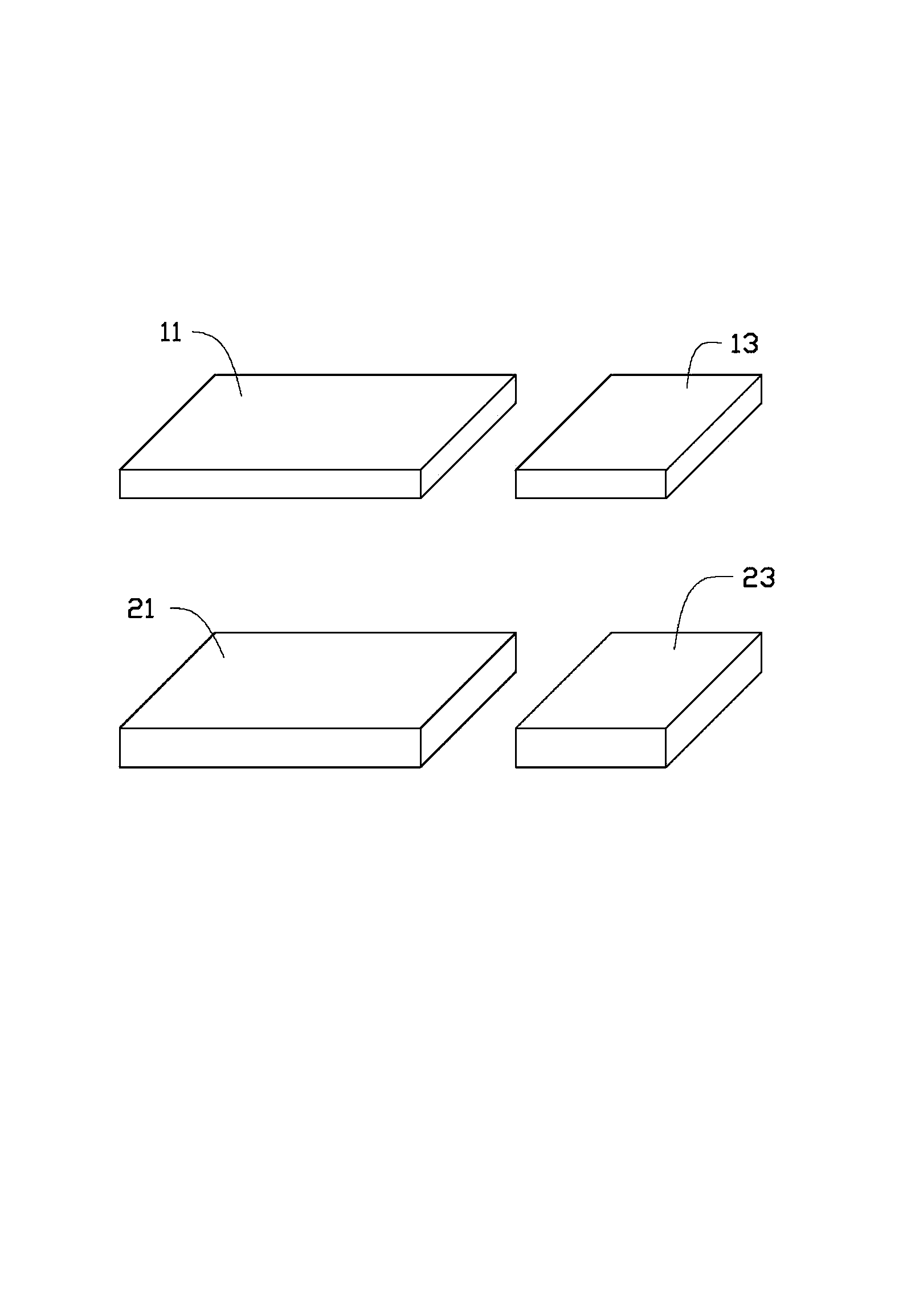

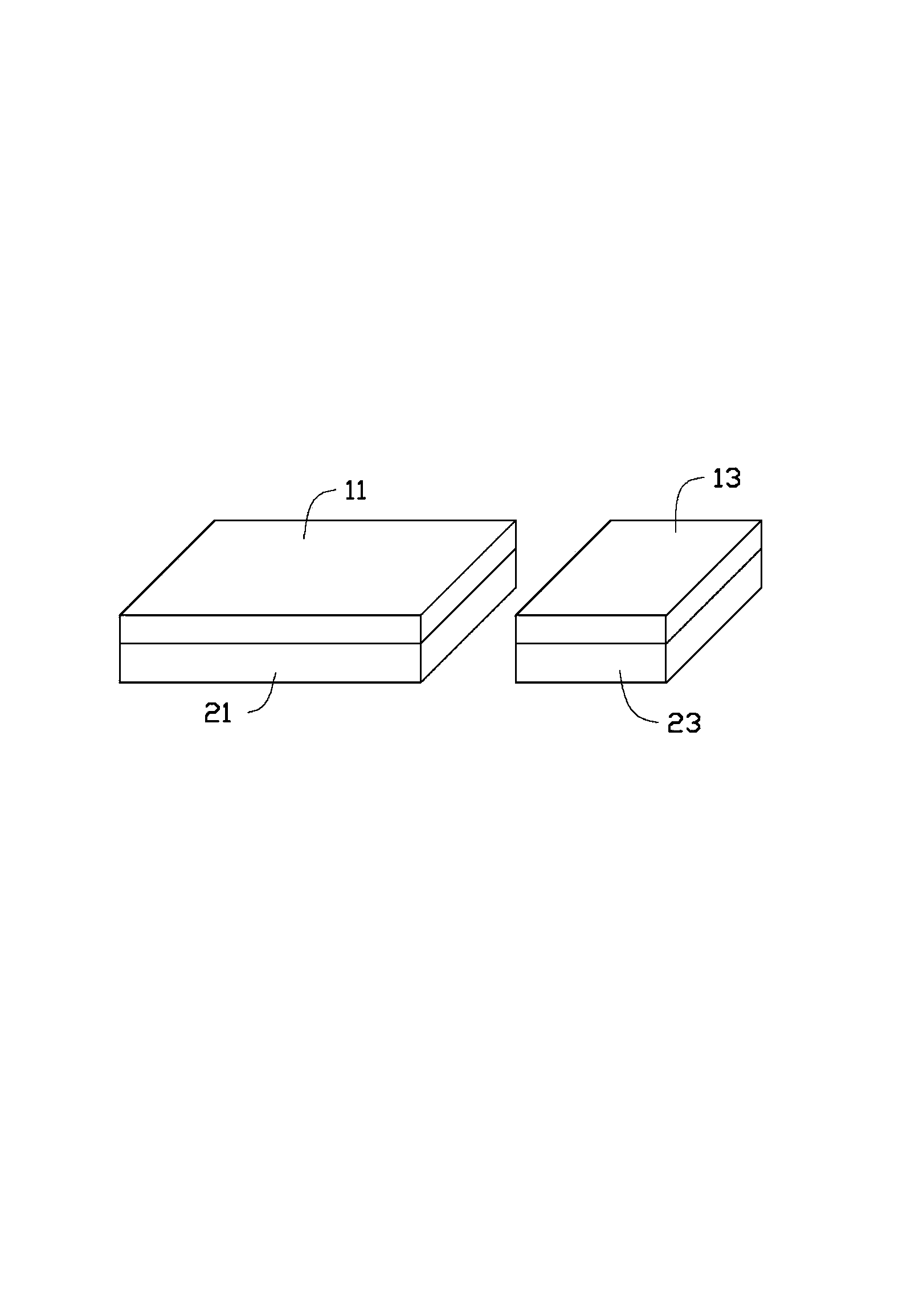

[0021] A first electrode 11 and a second electrode 13 are provided, and a first barrier wall 15 and a second barrier wall 17 are respectively formed on one side surface of the first electrode 11 and the second electrode 13;

[0022] A substrate 30 is provided, the first electrode 11 and the second electrode 13 are combined on the substrate 30 to form a base 40, the first electrode 11 and the second electrode 13 are separated from each other by the substrate 30, and the first electrode 11 and the second electrode 13 are separated from each other by the substrate 30. A retaining wall 15 and a second retaining wall 17 are arranged at intervals;

[0023] A package body 50 with a receiving cup 51 is formed on the top surface of the base 40, and the first retaining wall 15 and the second retaining wall 17 are exposed on the outer su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com