Ultrasonic motor driver

A technology of ultrasonic motor and driver, applied in the direction of generator/motor, electrical components, piezoelectric effect/electrostrictive or magnetostrictive motor, etc., can solve the problems of dispersion, low control precision, insufficient frequency resolution, etc. Achieve the effects of increasing current detection and protection, solving large fluctuations in speed, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the technical scheme of invention is described in detail:

[0029] The controllable clock module of this controller adopts a voltage-controlled oscillator.

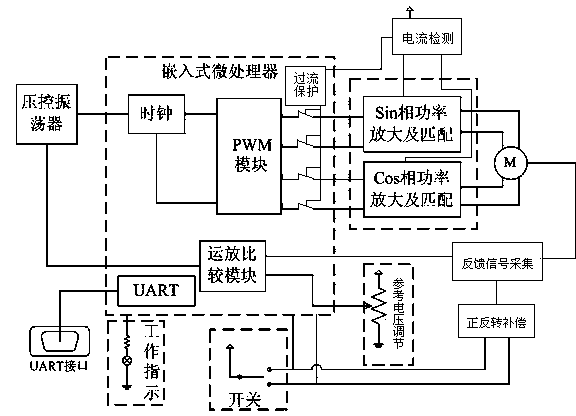

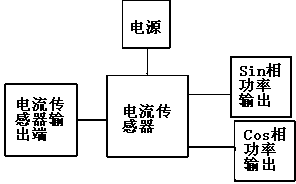

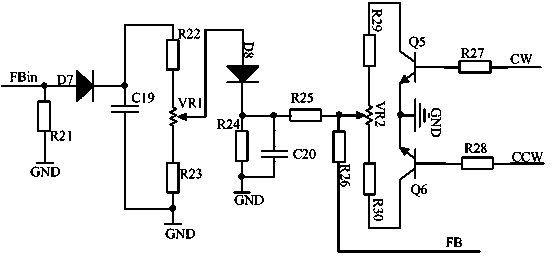

[0030] Such as figure 1 As shown, an ultrasonic motor driver includes an embedded microprocessor, a voltage-controlled oscillator, a two-phase power amplification and matching module, a feedback signal acquisition module, a current detection module, a forward and reverse compensation module, a switch, a working indication module, and a reference Voltage regulation module, UART interface module; Wherein, described embedded microprocessor comprises clock module, PWM module, operational amplifier comparison module, UART module; Described two-phase power amplification and matching module are Sin phase power amplification and matching module and Cos Phase power amplification and matching module; the output of the voltage-controlled oscillator is connected to the input sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com