Printed circuit board, manufacturing method thereof and electronic device

A technology for printed circuit boards and manufacturing methods, applied in printed circuit parts, structural connection of printed circuits, multi-layer circuit manufacturing, etc., can solve problems such as poor drop resistance and lack of elasticity in the PCB area, and achieve strong drop resistance , to achieve the effect of sticking devices on both sides and facilitating the shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The main realization principles, specific implementation modes and corresponding beneficial effects of the technical solutions of the embodiments of the present invention will be described in detail below in conjunction with each accompanying drawing.

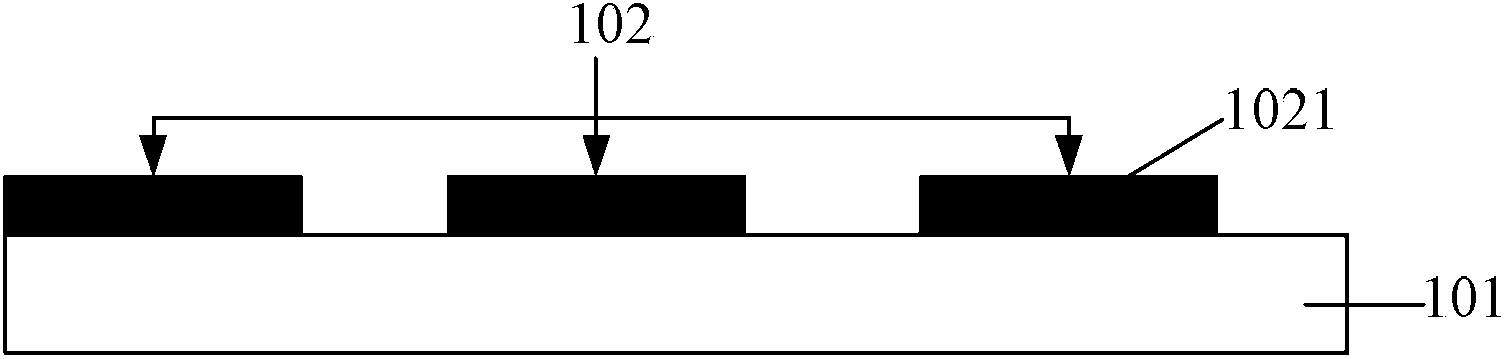

[0035] In order to solve the problems existing in the prior art, the embodiment of the present invention provides a printed circuit board, such as figure 1 shown, including:

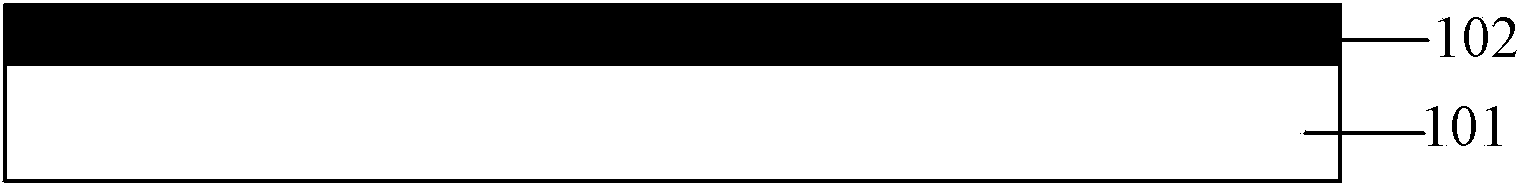

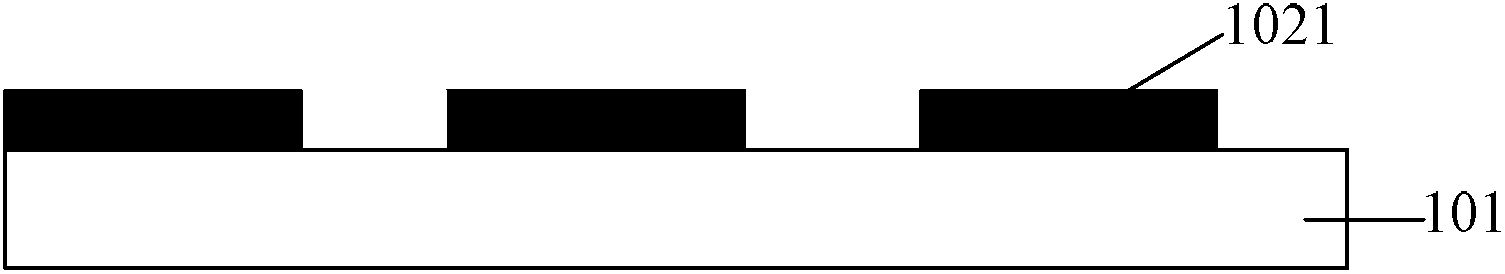

[0036] The first circuit board 101 whose etched flexibility parameter is the first parameter and the second circuit board 102 whose etched flexibility parameter is the second parameter, the first parameter is greater than the second parameter;

[0037] Wherein, the etched first circuit board 101 is connected to the etched second circuit board 102 .

[0038] When the etched second circuit board 102 includes at least two independent second circuit sub-boards 1021, at least two of the independent second circuit sub-boards 1021 pass through at least a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com