Glass bottle with good crack resistance and preparation process thereof

A technology of anti-crack performance and preparation process, which is applied in the direction of glass recycling, bottles, rigid containers, etc., can solve the problems of inability to recycle, unfavorable energy saving and environmental protection, and general corrosion resistance, so as to improve the safety of use and benefit energy saving and environmental protection , The effect of strong alkali corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

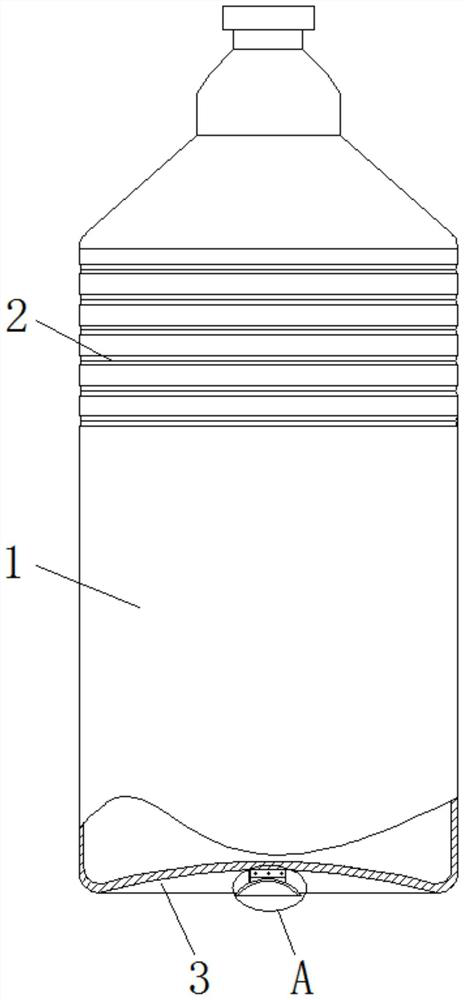

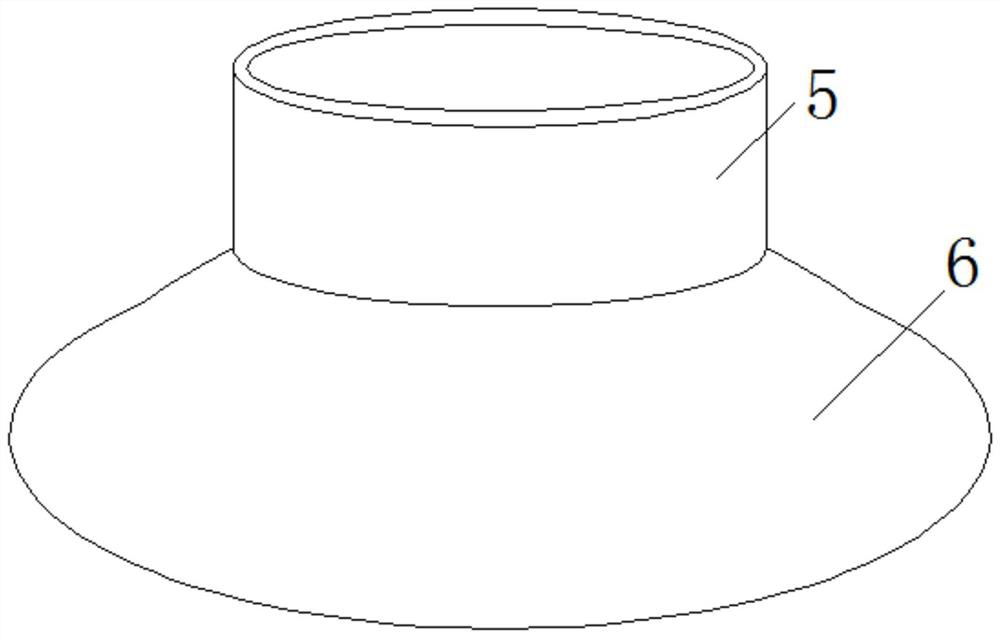

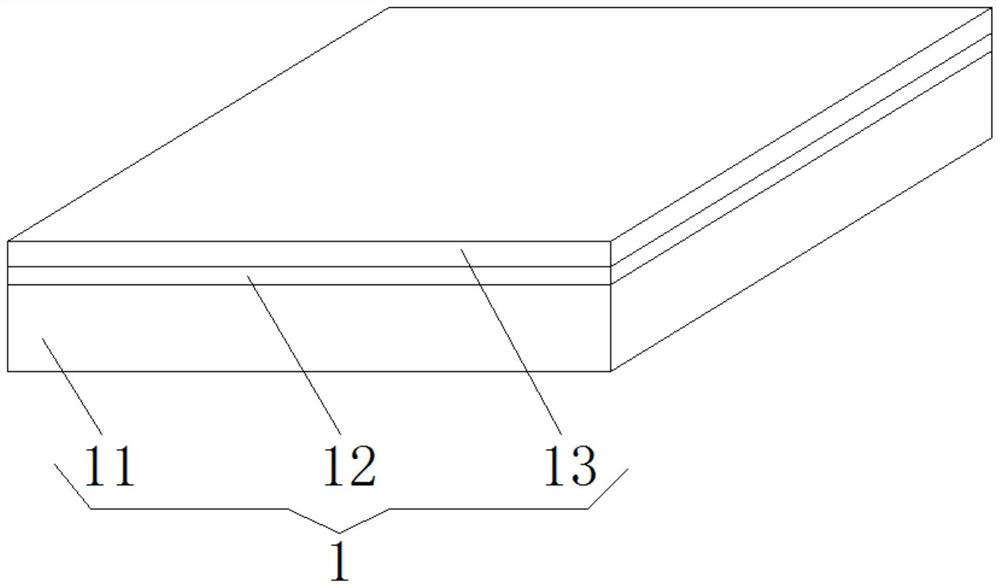

[0028] see Figure 1-Figure 4 , a glass bottle with good crack resistance, comprising a bottle body 1, the outer wall of the bottle body 1 is provided with an anti-slip groove 2, and the upper half of the bottle body 1 is evenly provided with an anti-slip groove 2 to avoid slipping during the hand-held process, The bottom of the bottle body 1 is provided with a recessed groove 3, the middle of the recessed groove 3 is provided with a cylinder 4, the outer wall of the cylinder 4 is sleeved with a rubber sleeve 5, and the bottom of the rubber sleeve 5 is provided with a suction cup 6, and the bottom of the suction cup 6 extends to Below the bottom of the bottle body 1, it is convenient to adsorb the desktop when placed. The interior of the bottle body 1 is sequentially provided with a base layer 11, a thermal insulation layer 12 and a corrosion-resistant layer 13 from the outside to the inside. The tin material can improve the heat insulation ability and prevent the contents fro...

Embodiment 2

[0039] see Figure 1-Figure 4 , a glass bottle with good crack resistance, comprising a bottle body 1, the outer wall of the bottle body 1 is provided with an anti-slip groove 2, and the upper half of the bottle body 1 is evenly provided with an anti-slip groove 2 to avoid slipping during the hand-held process, The bottom of the bottle body 1 is provided with a recessed groove 3, the middle of the recessed groove 3 is provided with a cylinder 4, the outer wall of the cylinder 4 is sleeved with a rubber sleeve 5, and the bottom of the rubber sleeve 5 is provided with a suction cup 6, and the bottom of the suction cup 6 extends to Below the bottom of the bottle body 1, it is convenient to adsorb the desktop when placed. The interior of the bottle body 1 is sequentially provided with a base layer 11, a thermal insulation layer 12 and a corrosion-resistant layer 13 from the outside to the inside. The tin material can improve the heat insulation ability and prevent the contents fro...

Embodiment 3

[0050] see Figure 1-Figure 4 , a glass bottle with good crack resistance, comprising a bottle body 1, the outer wall of the bottle body 1 is provided with an anti-slip groove 2, and the upper half of the bottle body 1 is evenly provided with an anti-slip groove 2 to avoid slipping during the hand-held process, The bottom of the bottle body 1 is provided with a recessed groove 3, the middle of the recessed groove 3 is provided with a cylinder 4, the outer wall of the cylinder 4 is sleeved with a rubber sleeve 5, and the bottom of the rubber sleeve 5 is provided with a suction cup 6, and the bottom of the suction cup 6 extends to Below the bottom of the bottle body 1, it is convenient to adsorb the desktop when placed. The interior of the bottle body 1 is sequentially provided with a base layer 11, a thermal insulation layer 12 and a corrosion-resistant layer 13 from the outside to the inside. The tin material can improve the heat insulation ability and prevent the contents fro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com