Device and system for continuously pressing and ironing clothing cut parts

A garment cutting and cutting technology, which is applied in the field of clothing production, can solve the problems of reducing the aesthetics of finished clothing, stains on the cutting, and high investment costs, so as to facilitate the stacking and collection of multiple cuttings, easy control, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention are described in detail below:

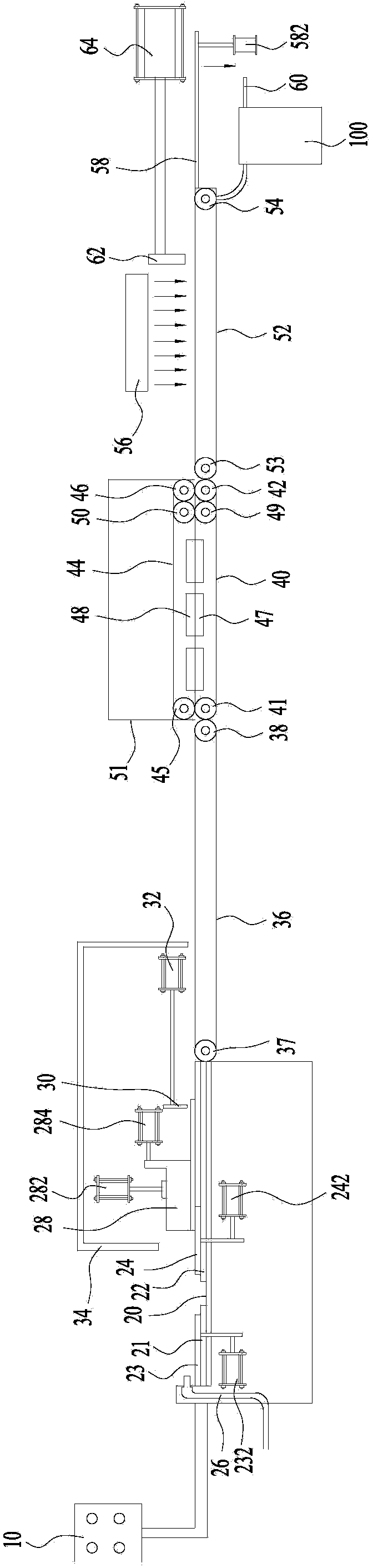

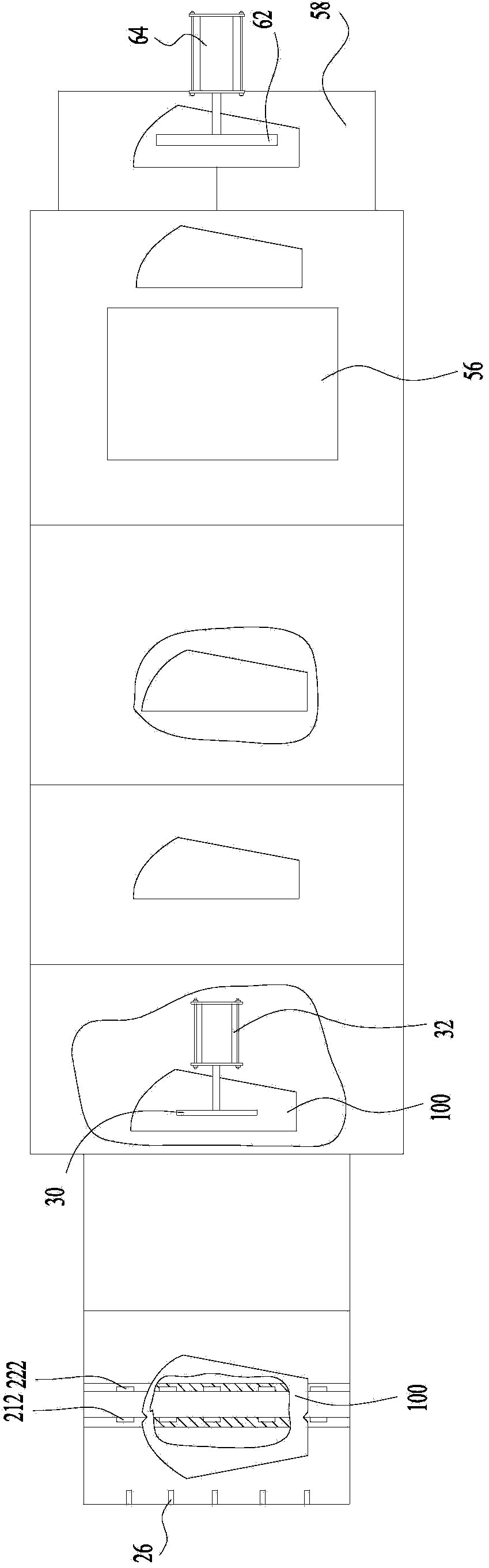

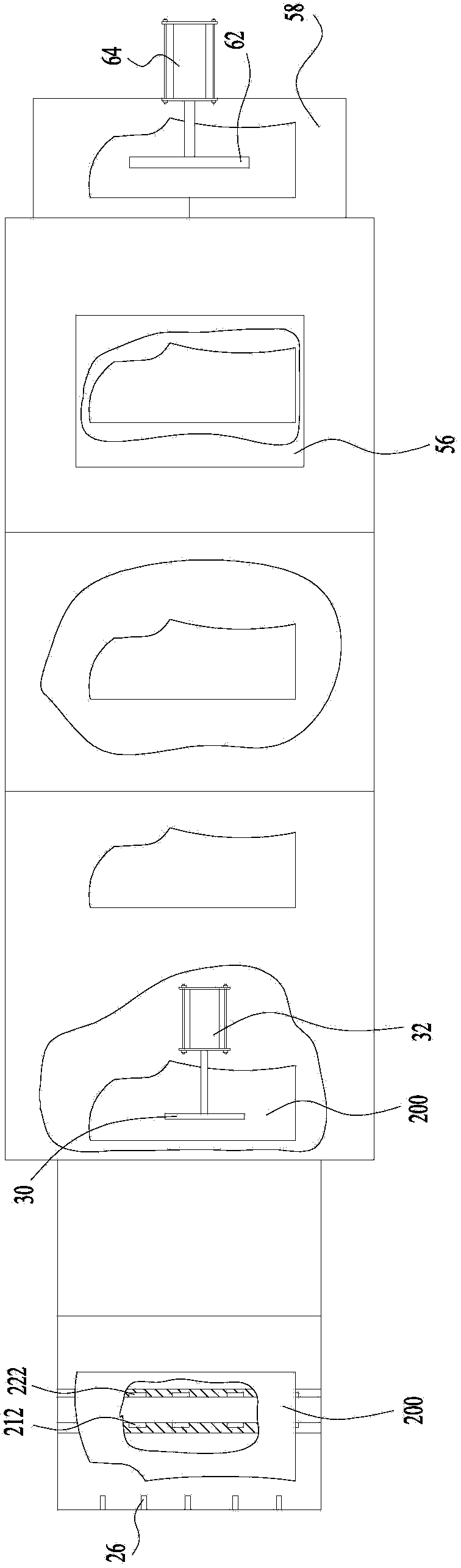

[0037] Such as figure 1 As shown, a continuous pressing device for cutting clothing pieces includes a controller 10, a piece folding device connected to the controller 10 and connected in sequence, a piece feeding device, a piece transmission device, and a pressing device , Cut piece transfer device and cut piece collection device. Wherein, the cut pieces are transferred between the cut piece folding device and the cut piece transmission device through the cut piece input device, the cut piece output device transfers the cut pieces to the cut piece collecting device, The piece collection device collects the pieces for the next process; and a cooling device is installed above the piece delivery device, and the pressed pieces are quickly cooled and shaped by the cooling device to keep the pieces in a folded state .

[0038]Manually place the cut piece on the cut piece folding device, and complete the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com